Tel

+44 (0)1424 856600

Fax

+44 (0)1424 856611

Technical Hotline

+44 (0)1424 856688

TECHNICAL INFORMATION

Technical information

252 |

Wire Basket

protects it against the action of external

agents. The passivation film or layer does not

allow these agents to interact, reducing or

stopping the chemical reaction from

happening.

IEC 61537 Standard classifies this steel’s

resistance to corrosion as Class 9B without the

passivation treatment and as Class 9Dwith

the passivation treatment.

Stainless Steel AISI 316L, denominated 14401

according to the numerical classification

established by the BS EN 10088 Standard has

the same characteristics regarding corrosion

as steel AISI 316, but o ers a higher degree of

welding and easier forming of the lengths

with a thickness of more than 6mm.

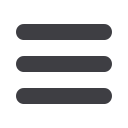

Dimensions

Height 35mm

StandardWire Basket

Working temperature

Material

Electrogalvanised (ELECTROZINC/EZ)

A steel base coatedwith a zinc layer by

electrolysis, bymeans of submerging the

lengths in a bath composed of a zinc solution,

in accordancewith BS EN ISO 2081. Depending

on the type of zinc layer, it shall have a di erent

degree of protection on the steel, avoiding

corrosion and enhancing the visual

appearance of the length.This treatment is

carried out once the length has been formed.

The IEC 61537 Standard classifies the degree

of resistance to corrosion of the system’s

components depending on the steel’s

electrolytic covering, belonging to Class 1

those with a minimum thickness of 5µm and

to Class 2 those of 12µm. Marshall-Tu ex uses

Class 2 as its standardmaterial in order to

guarantee the quality of its products against

corrosion. This treatment is used in dry

environments free of pollutants.

Hot Dip Galvanised Steel (HDG)

Laminated or rust removed galvanised after

forming steel according to BS EN ISO 1461

Standard. The steel’s protection is covered by a

zinc coating which varies depending on the

steel’s thickness, o ering a uniform covering.

The zinc coating’s thickness depends on the

thickness of the base material. The IEC 61537

Standard classifies the resistance against

corrosion of these galvanised steels as Class 5

for the covering of 45µm, Class 6 for 55µm,

Class 7 for 70µm and Class 8 for 85µm. Hot dip

galvanised steel is used in humid

environments, granting a high protection

during adverse atmospheric situations, light

chemical situations, light marine situations

and urban situations.

Stainless Steel AISI 316 (I316)

Denominated 14401 according to the

numerical classification established by the BS

EN 10088 Standard. Steel’s protection

happens due to the great a nity which

metals such as chromiumhave with oxygen,

which gives place to the creation of a

protective chromium oxide layer which avoids

the corrosion of iron. Type I316 stainless steels

are similar to type 1304, but they contain a

2.5% of molybdenumwhich confers it a

greater resistance to localised corrosion. It is

ideal for use in very corrosive environments,

even at high temperatures. Under special

conditions, and always under order, there is

the possibility of conducting a passivation

process. Passivation is a treatment which

enhances stainless steel’s protection against

corrosion by means of forming a relatively

inert film on the surface of a material which

Height 65mm

StandardWire Basket and Fast-CouplingWire

Basket

Height 105mm

StandardWire Basket and Fast-CouplingWire

Basket

Cover

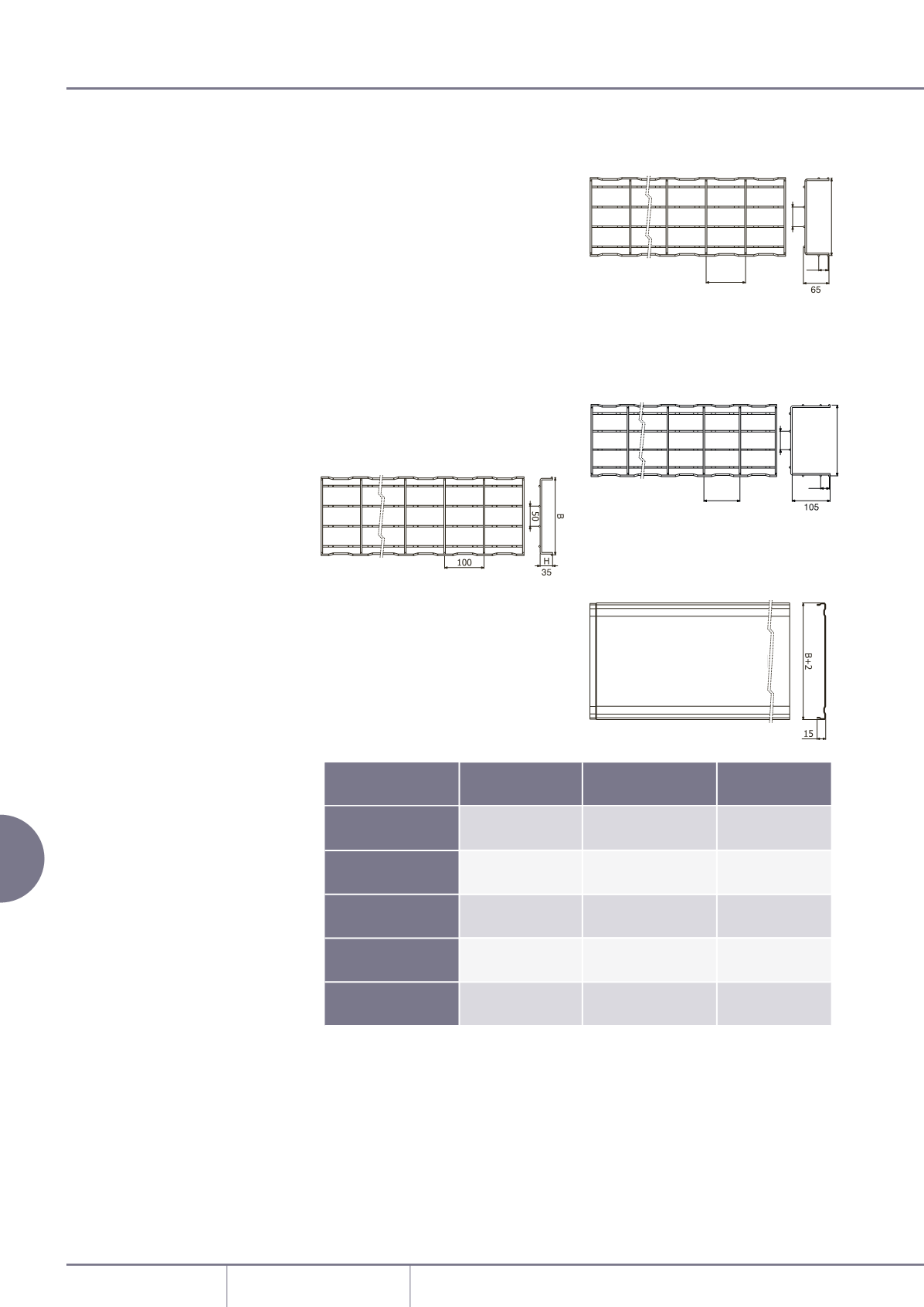

Minimum working Maxiumum working According to

temperature

temperature

Standard

Standard Wire

-50°c

+150°c

IEC 61537

Basket 35mm

Standard Wire

-50°c

+150°c

IEC 61537

Basket 65mm

Standard Wire

-50°c

+150°c

IEC 61537

Basket 105mm

Fast-Coupling Wire

-50°c

+150°c

IEC 61537

Basket 65mm

Fast-Coupling Wire

-50°c

+150°c

IEC 61537

Basket 105mm

100

B

50

25

H

100

B

50

25

H

15