91

All dimensions (mm) are nominal

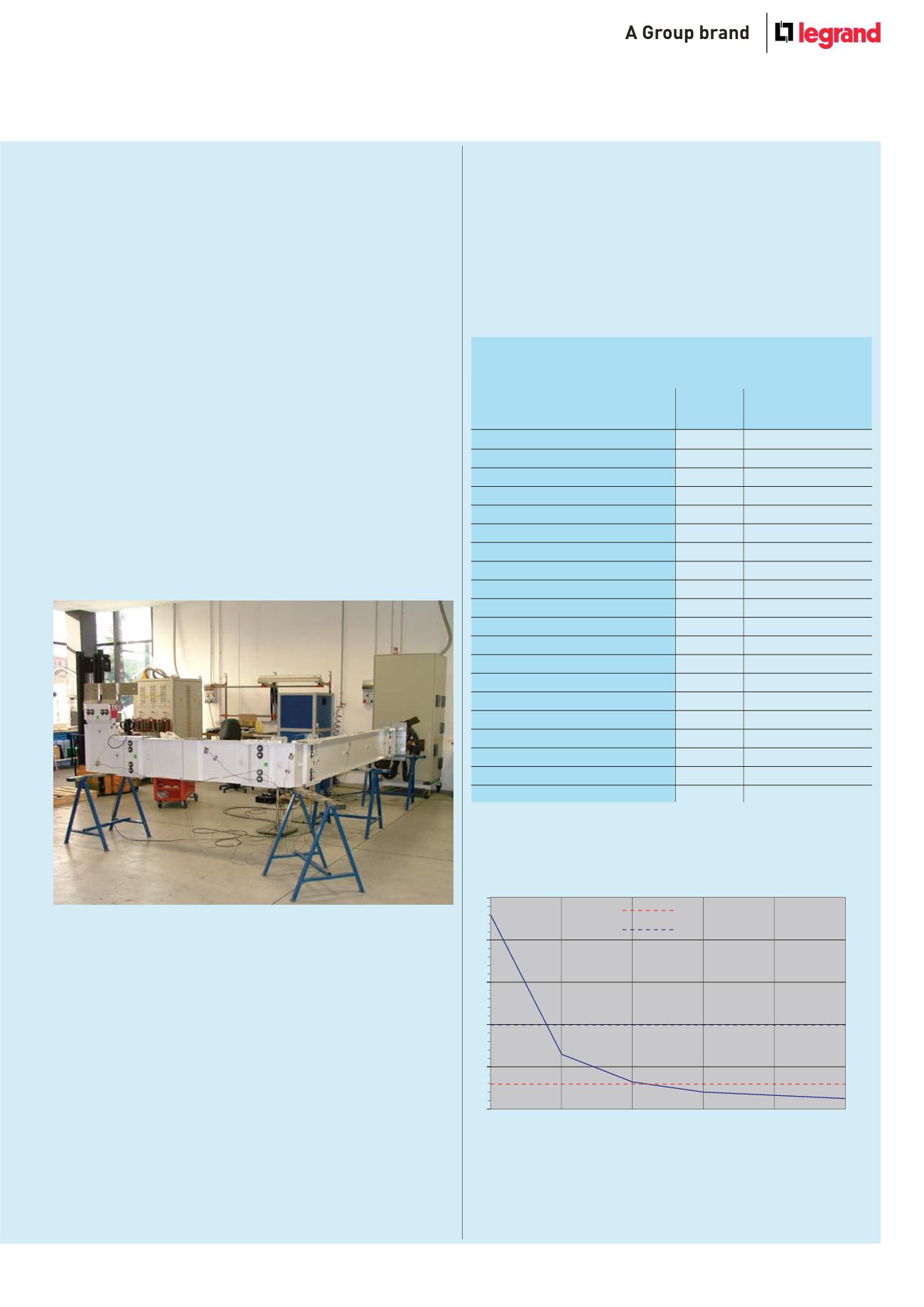

One-dimensional trend of the magnetic induction near the junction.

The blue dash shows the ‘objective’ level and the red dash shows

the ‘quality objective’ required by law

n

Measurement of magnetic induction

Since 1994, with a study carried out by Chalmers University of

Technology of Goteborg, Legrand has taken an interest in the issues

linked with the electromagnetic emissions in their Zucchini products,

keeping at the forefront of the latest legislative directive, which has only

recently imposed the quality standards that were already widely met by

Zucchini busbar trunking systems

The ACAE (Association for the Certification of Electric and Electronic

Equipment) certified internal laboratory is capable of carrying out the

measurement of the electromagnetic emissions of busbar trunking

systems. This measurement is nowadays one of the tests to which the

products are subjected before they reach the market

The busbar trunking system in itself already minimises electromagnetic

emissions, which are much lower when compared with those generated

by cables with the same current intensity

It is a well-known fact that the electromagnetic field is the result of the

superimposition of two fields : the electric and the magnetic field

The first is totally shielded by the equipotential metal casing of the

busbar trunking system, while the second is very low due to the

intrinsic characteristic of the busbar trunking system. More precisely,

due to the fact that busbar conductors are extremely close inside

the busbar package, the three busbar conductors, crossed by three

balanced currents displaced by 120°, induce fields that tend to overlap,

cancelling one another, therefore resulting in an extremely low external

impact

However, also in conditions of imperfect current balance, the metal

casing of the busbar trunking system is capable of reducing most of the

magnetic field, which otherwise would spread through the surrounding

environment

The laboratory tests carried out show how the magnetic induction

emitted by SCP busbar trunking systems, measured at a distance of

approximately one metre, is well below the critical value of 3 μT

With Legislative Decree DPCM dated 8/7/2003, Italian law set the first

exposure limit at 100 μT

In addition, in locations where attendance is expected for no less than

four hours a day, an attention value of 10 μT has been set, to avoid

possible long term effects on health

In the decree, the 3 μT threshold is indicated as the ‘quality objective’.

However, as the product is intended for the European and world

market, low magnetic emission is a fundamental point that cannot be

disregarded, to ensure a presence in foreign countries : one example

of this is Germany, where for over 10 years the regulation has set a

cautionary limit of 3 μT as the maximum permitted threshold in certain

structures, for example hospitals, so much so that in these types of

environments the busbar trunking system has become a mandatory

choice, as well as a high quality one

Testing at Legrand’s laboratory in Italy for the approval

certification of Zucchini SCP busbar trunking systems

n

Measurement of magnetic induction (continued)

The high quality standard guaranteed by busbar trunking systems can

be further appreciated by comparing the emission values measured

against those of other commonly used equipment, as taken from table

7·1 of CEI 211-6 standard

The measurements obtained on aluminium SCP busbar trunking

systems with ratings of 2500 A (carried out in compliance with the

requirements of the technical product standard CEI EN 60439-2), show

that the magnetic induction generated by the busbar is in the range of

1·5 - 2 μT at a distance of one metre from the busbar itself

These values also apply near the junction, which is considered the

critical point due to the wider distance between the busbar conductors

in this position

Levels of exposure to industrial frequency magnetic field sources

(table 7.1 from CEI 211-6 standard)

Magnetic

Source

induction

Distance

(µT)

Electric shaver

150-240

on the face

Hairdryer

1-13

10-20 cm

Blender

0·9

40 cm

12 V, 20 W halogen lamp

0·5

30 cm

Aerosol therapy equipment

20-50

20-30 cm

Electric blanket

2

on contact

21 inch television set

0·3

50 cm

Washing machine

3·4

50 cm

Dishwasher

0·05

50 cm

Electric oven

0·4

20 cm

600 W drill

2

on the chest

100 W welding machine

14·5

on the chest

225 W grinder

0·8

40 cm

1100 W compressor

8·2

40 cm

2150 W arc welding machine

23·2

40 cm

75 MW, 55-65 kA, 150 t arc oven

100-270

in proximity

Electric scalpel

2·9

in proximity

Battery charger

22·9

in proximity

Echograph

0·8

operator position

Projector

2·3

20 cm

B (μ T)

Objective level

Quality objective level

25

20

15

10

5

0

20 40 60

80 100 120

CM