100mm

1.25 to 1.50m

100mm

Industrial Trunking

General notes

Prior to installation strike a line of trunking using a plumb and

chalk line for vertical, and spirit levels for horizontal runs.

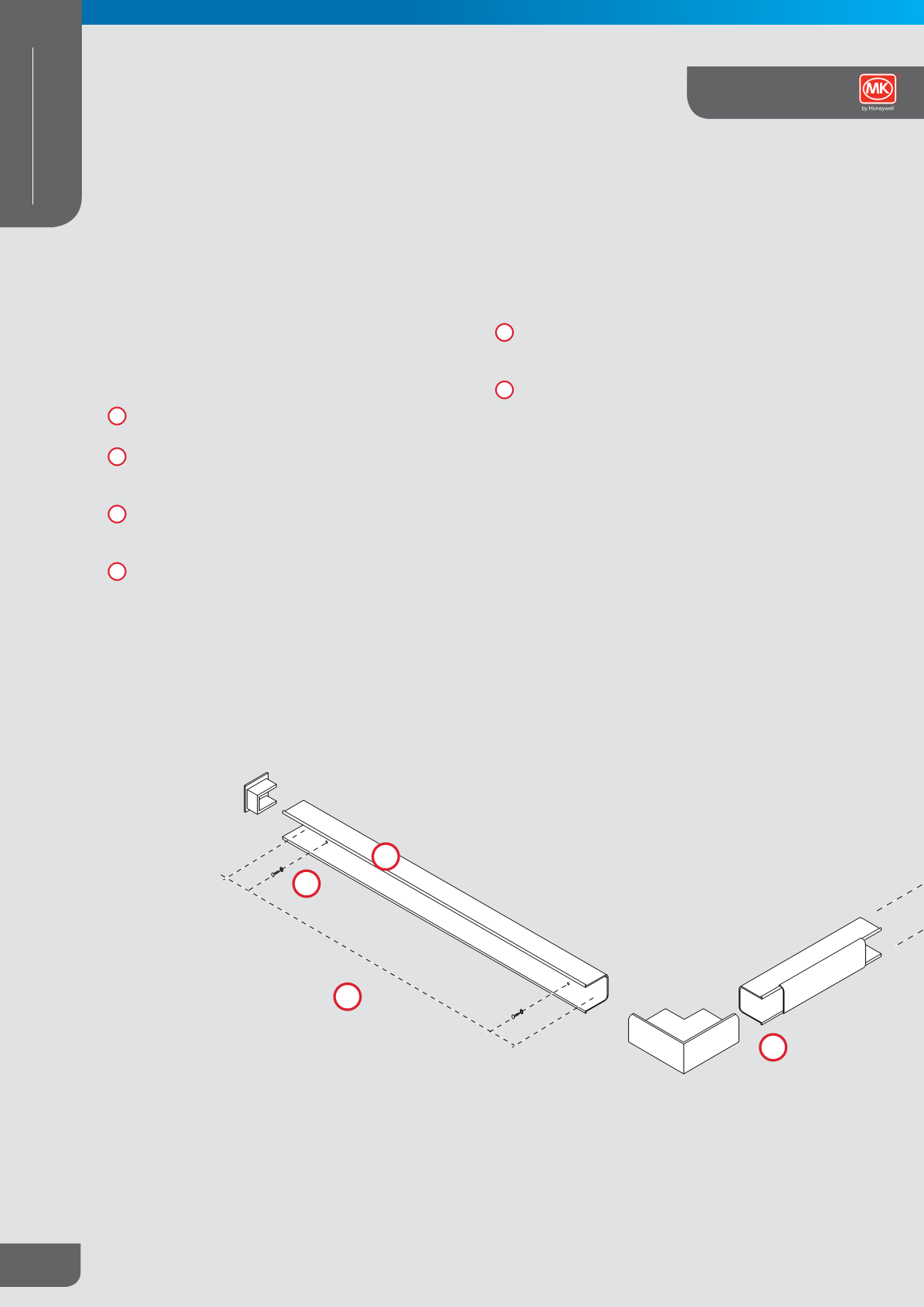

Fixing

1

Fix trunking with screws. It is essential that the hole in the

trunking is considerably oversized to allow for expansion.

2

Washers should be used under the head of the screw. The

screw should not be tightened to its full extent to allow for

movement.

3

For suspended trunking it is advisable to provide fixings

every 1.25 m to 1.5 m and a maximum of 100mm either side

of coupling.

4

Trunking and lid joints should be staggered to increase the

strength of couplings.

Installation Guide

1

2

3

4

Fixing lids

5

Fix lid by sliding it onto the trunking at one end, aligning it to

the run of trunking and then curving the cover at the same

time as pressing the continuous clip into the trunking gap.

6

To remove lid grasp the trunking firmly at one end and pull in

peeling motion so that the cover is gradually freed along its

whole length.

mkelectric.co.uk660

CABLE MANAGEMENT

PERIMETER AND

DISTRIBUTION

Ega Industrial

Technical