WIRING DEVICES

Technical Hotline

+44 (0)1268 563720

INGRESS PROTECTED

IP66

551

Installation

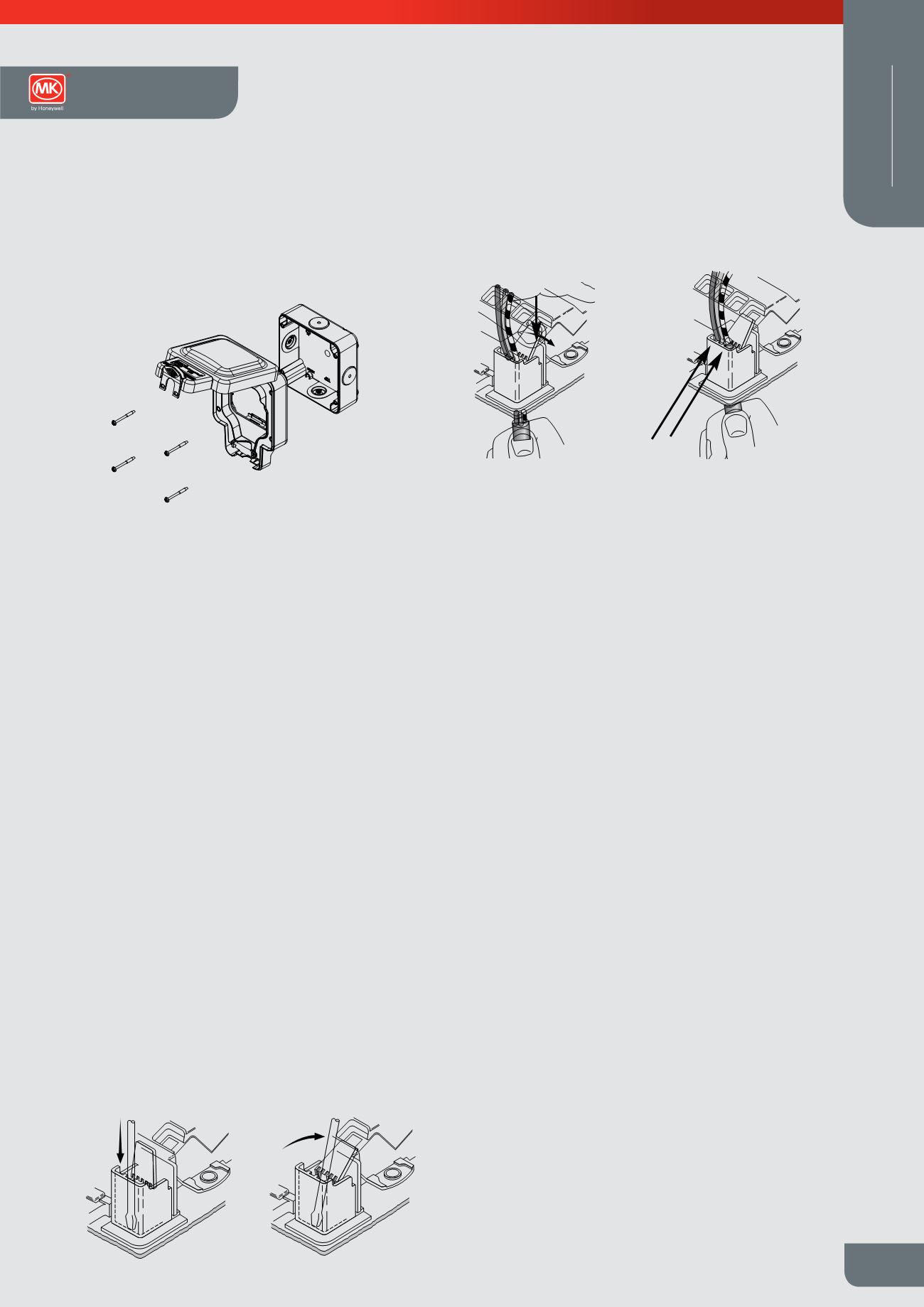

11.

Wire and fit the front plate. Ensure the seal is correctly located

and the cables are not trapped or pinched.

When installing connection units using the

front flexible cable clamp

1.

Strip back the outer sheath on the appliance flexible LOAD

cable and trim wires to 55mm in length. Do not trim the

insulation on the three individual cables for the moment.

2.

When using cables of 10mm or more in diameter, it is

necessary to prestress the cable clamp before attempting to

load the cable.

3.

To pre-stress the clamp insert a flat bladed screwdriver into the

cord grip as shown in fig. 6a and flex the clamping jaw open

until it touches the grey base moulding fig. 6b. Then remove

the screwdriver.

IMPORTANT: The clamp must not be re-used for cables below 6mm

diameter after pre-stressing.

4.

Cables below 10mm diameter do not need the cable clamp

pre-stressed and the installation from this point is the same for

all products.

5.

To assist pushing the load cable through the front of the

product, ease the clamping jaw pressure by holding the

product securely in one hand and pushing the tab firmly with

your thumb in the direction shown in fig. 7a.

6.

Continue pushing the cable through the clamp until the outer

sheath reaches the cable stops. See fig. 7b. The jaws must

clamp on the outer sheath.

7.

Carefully strip back the insulation on all three cables to expose

10mm of the conductor.

8.

Ensure all conductors are connected to the appropriate terminals.

NOTE: Terminal screws must be securely tightened. Pull on each cable to

ensure that the terminal screw has securely fixed the conductor.

WHEN INSTALLING CONNECTION UNITS USING THE FRONT FLEXIBLE

CABLE CLAMP

1. Strip back the outer sheath on the appliance flexible LOAD cable and

trim wires to 55mm in length. Do not trim the insulation on the three

individual cables for the moment.

2. When using cables of 10mm or more in diameter, it is necessary to pre-

stress the cable clamp before attempting to load the cable.

3. To pre-stress the clamp insert a flat bladed screwdriver into the cord

grip as shown in

fig. 6a

and flex the clamping jaw open until it touches

the grey base moulding

fig. 6b

. Then remove the screwdriver.

IMPORTANT: The clamp must not be re-used for cables below 6mm

diameter after pre-stressing.

4. Cables below 10mm diameter do not need the cable clamp pre-stressed

and the installation from this point is the same for all products.

5. To assist pushing the load cable through the front of the product, ease

the clamping jaw pressure by holding the product securely in one hand

and pushing the tab firmly with your thumb in the direction shown in

fig. 7a

.

6. Continue pushing the cable through the clamp until the outer sheath

reaches the cable stops. See

fig. 7b

. The jaws must clamp on the outer

sheath.

7. Carefully strip back the insulation on all three cables to expose 10mm of

the conductor.

8. Ensure all conductors are connected to the appropriate terminals.

Terminal screws must be securely tightened. Pull on each cable to

ensure that the terminal screw has securely fixed the conductor.

9

10

11

13

14

15

G. SPECIFICATION

All MK products are manufactured in accordance with

ISO9001: 2008 and where applicable, comply with the EMC and/or LV

directives 89/336/EEC and 73/23/EEC.

Operating Temperature range –5ºC to +40ºC

H. GUARANTEE

The company undertakes to replace or re

become defective within 20 years in the c

Device products and 10 years in the case

Wiring Device products and all Circuit Pr

products solely as a result of faulty materi

Understandably if the product has not be

accordance with the company’s instructio

appropriately or if any attempt has been

the product in any way the guarantee will

This guarantee states the company’s entir

cover consequential loss or damage or in

defective product. This guarantee does n

statutory or other rights of the customer.

Repair of goods after the guarantee pe

If the product fails under normal use afte

contact your local dealer or stockist.

MK Electric Limited wishes to make it cle

designs of the products that it manufactu

leaflet) and that it will take all necessary a

against any party found to be manufactur

otherwise dealing with any article which i

intellectual property in its own products,

therein.

Tab Pushed

This Way

Installatio

flexible l

cables

Figure 7a

Figure 6a

Pre-stressing the

clamp for cables

10mm in di

10. Before wiring and fitting the front plate, position the seal on the front

plate. Ensure the holes are aligned and seal is aligned with the ribs on

the mounting box and the cables are threaded through the seal and

screws are fully tightened.

11. Wire and fit the front plate. Ensure the seal is correctly located and the

cables are not trapped or pinched.

Figure 5

Figure 8

50048741:RevA 21/4/10 09:33 Page 2

Testing

Test the completed installation in accordance with the latest

edition of the IET wiring regulations (BS 7671).

Service and Maintenance

CLEANING

1.

The exterior of the product must only be cleaned with a

solution of mild detergent (e.g. washing up liquid) and

warm water.

E. TESTING

Test the completed installation in accordance with the latest e

IEE wiring regulations (BS 7671).

F. SERVICE AND MAINTENANCE

CLEANING

1. The exterior of the product must only be cleaned with a soluti

detergent (e.g. washing up liquid) and warm water.

CABLE SEAL CAPSULE REPLACEMENT

1. Note the orientation of the cable seal capsules in the lid an

Figure 6a

Figure 6b

Pre-stressing the front cable

clamp for cables greater than

10mm in diameter

CONNECTION UNITS USING THE FRONT FLEXIBLE

ter sheath on the appliance flexible LOAD cable and

m in length. Do not trim the insulation on the three

for the moment.

s of 10mm or more in diameter, it is necessary to pre-

lamp before attempting to load the cable.

clamp insert a flat bladed screwdriver into the cord

ig. 6a

and flex the clamping jaw open until it touches

ulding

fig. 6b

. Then remove the screwdriver.

lamp must not be re-used for cables below 6mm

stressing.

m diameter do not need the cabl clamp pre-stressed

n from this point is the same for all products.

the load cable through th f ont f the product, ease

pressure by holding the product securely in one hand

b firmly with your thumb in the direction shown in

fig. 7a

.

the cable through the clamp until the outer sheath

stops. See

fig. 7b

. The jaws must clamp on the outer

k the insulation on all three cables to expose 10mm of

tors are connected to the appropriate terminals.

ust be securely tightened. Pull on each cable to

rminal screw has securely fixed the conductor.

10

11

14

15

ION

manufactured in accordance with

where applicable, comply with the EMC and/ r LV

C and 73/23/EEC.

ure range –5ºC to +40ºC

H. GUARANTEE

The company undertakes to replace or repair at its discretion products that

become defective within 20 years in the case of electromechanical Wiring

Device products and 10 years in the case of mains related electronic

Wiring Device products and all Circuit Protection and Cable Manag ment

products solely as a result of faulty materials and or workmanship.

Understandably if the product has not been installed or maintained in

accordance with the company’s instructions, has not been used

appropriately or if any attempt has been made to rectify, dismantle or alter

the product in any way the guarantee will be invalidated.

This guarantee states the company’s entire liability. It does not extend to

cover consequential loss or damage or installation costs arising from the

defective product. This guarantee does not restrict or infringe the normal

statutory or other rights of the customer.

Repair of goods after the guarantee period

If the product fails under normal use after expiry of the guarantee period,

contact your local dealer or stockist.

MK Electric Limited wishes to make it clear that it owns all the original

designs of the products that it manufactures (whether or not listed in this

leaflet) and that it will take all necessary action in any part of the world

against any party found to be manufacturing, distributing, selling or

otherwise dealing with any article which infringes the Company’s

intellectual property in its own products, or any other right of the company

therein.

Figure 7b

Tab Pushed

This Way

Installation of

flexible load

cables

Figur 7a

Cable

Stops

Figure 6a

Figure 6b

Pre-stressing the front cable

clamp for cables greater than

10mm in diameter

Masterseal Plus™

Technical