6/22

Electronic motor protective relay

Selection aid

2010

CA08103002Z-EN

www.eaton.comEngineering

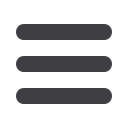

1)

IF: Internal fault

Inputs

Outputs

A 1/A 2

Rated control voltage

95/96

NC overload/thermistor

T 1/T 2

Thermistor sensor

97/98

N/O overload/thermistor

C 1/C 2

SSW core-balance transformer

05/06

NC contact freely assignable

Y 1/Y 2

Remote reset

07/08

N/O contact freely assignable

Switchgear and cable sizing corresponding to the respective starting inertia (CLASS) for ZEV and ZEB

Switchgear is designed according to "CLASS 10" requirements for both normal and overload operation conditions. In order for the

switchgear (circuit-breaker and contactor) and the cables not to be overloaded with long tripping times, they must be overdimensioned

accordingly. The rated operational current, I

e

,

for switchgear and cables can be calculated with the following current factor taking the

tripping class into account:

Trippling class

Class 5

Class 10 Class 15 Class 20 Class 25 Class 30 Class 35 Class 40

Current factor of

rated operational

current I

e

1.00

1.00

1.22

1.41

1.58

1.73

1.89

2.00

Rated motor currents < 1 A

When working with the ZEV-XSW-25 to ZEV-XSW-145 push-through sensors, the motor feeder cables for each phase are pushed

through the corresponding-push-through openings. For motor currents smaller than 1 A, the motor feeder cables are placed in

loops with the ZEV-XSW-25 unit. The specific number of loops depends on the rated motor current.

Number of loops n

4

3

2

Rated motor current I

N

A 0.25…0.32

0.33…0.49

0.5…0.99

Set current on the relay I

E

between the lowest and highest values

A 1.00…1.28

1.00…1.47

1.00…1.98

The device's set current, I

E

,

is calculated as follows: I

E

= n x I

N

5 10 15 20

25 30 35 40

IF

1)

IF

1)

Class

Y1

T1

T2

Y2

C2

C1

A1 A2

95 97 05 07

96 98 06 08

~ =

N

L3

L2

L1

M

3

~

Z2

Z1

l

%

L1 L2 L3

PE

PE

I

e

I

e

> 105%

I

e

> 105%

!

µP

!

1 – 820

A

Mode

Test

Reset

Up

Down

Reset

Menu

ON OFF

Reset

Manual Auto

Class

Fault

Free

parameter 1

Free

parameter 2

Free

parameter

1

Free

parameter

2

ZEV, ZEB