26

A-2M.. series lugs are

manufactured from elec-

trolytic Copper tube con-

forming to EN13600.

The tube dimensions are

designed to optimise elec-

trical conductivity and me-

chanical strength.

Palms feature double stud

holes at standard 44.5mm

centres.

Other configurations are

available upon request.

Lugs are annealed to en-

sure ductility and satisfac-

tory performance when

subjected to deformation

and vibration.

Inspection holes facilitate

verification of full conduc-

tor insertion, while the

barrel length has been de-

termined to allow easy and

accurate positioning of the

crimping dies.

Lugs are electrolytically Tin

plated to avoid oxidation.

Details of the appropriate

crimping tools and dies

are shown on pages 178

to 179.

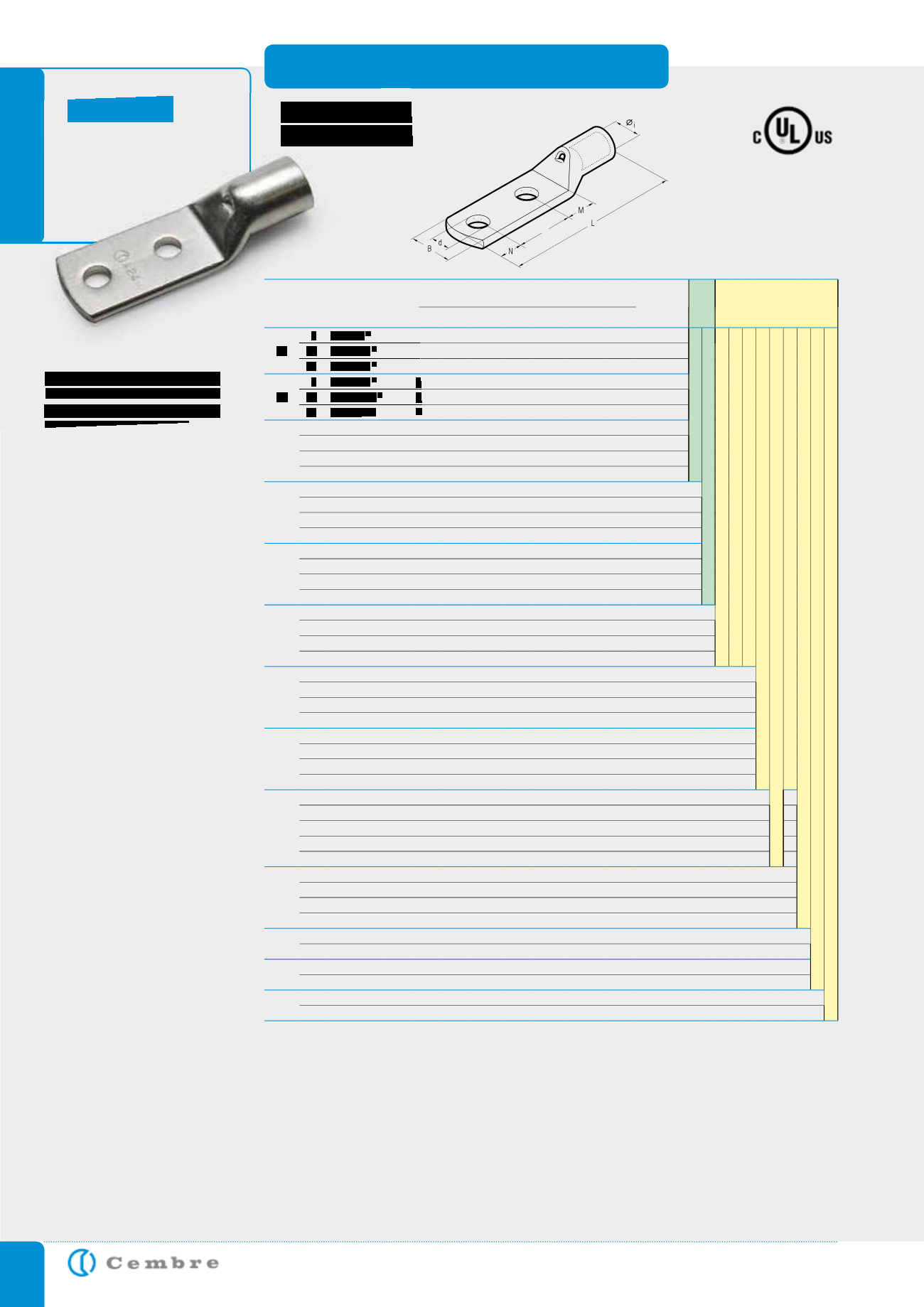

COPPER TUBE CRIMPING LUGS

double hole fixing

for Copper conductors

A-2M

E

Cond.

Size

AWG

Ø

Stud

in.

Ref.

D i m e n s i o n s i n.

Quantity

Bag

Mechanical

Tools

Hydraulic

Tools

Ø

i

B M N E

L

d

35

8

A7-2M8

8,9 21,0 13,0 11,0 44,5 90,0 8,4

100

TN 70 SE

TN 120 SE*

B 35-45MDE

B 35-50MDE

HT 45-E

HT 51 B 550E

RH 50 B 500E

HT 81-U RHU 81

HT 120 and tools and heads with 130 kN crimping force

ECW-H3D

RHU 520

10

A7-2M10

8,9 19,0 11,0 10,0 44,5 87,0 10,5

100

12

A7-2M12

8,9 21,0 16,0 14,0 44,5 96,0 13,2

100

50

8

A10-2M8

10,0 19,0 11,0 11,0 44,5 92,0 8,4

50

10

A10-2M10

10,0 20,0 13,0 11,0 44,5 94,0 10,5

50

12

A10-2M12

10,0 21,0 16,0 14,0 44,5 100,0 13,2

50

70

8

A14-2M8

11,3 21,0 11,0 11,0 44,5 95,5 8,4

50

10

A14-2M10

11,3 21,0 13,0 11,0 44,5 97,5 10,5

50

12

A14-2M12

11,3 22,0 16,0 14,0 44,5 103,5 13,2

50

14

A14-2M14

11,3 25,0 18,0 16,0 44,5 107,5 15,0

50

95

10

A19-2M10

13,5 25,0 13,0 11,0 44,5 104,0 10,5

25

12

A19-2M12

13,5 25,0 16,0 14,0 44,5 110,0 13,2

25

14

A19-2M14

13,5 25,0 18,0 16,0 44,5 114,0 15,0

25

16

A19-2M16

13,5 25,0 19,0 17,0 44,5 116,0 17,0

25

120

10

A24-2M10

15,2 28,5 13,0 11,0 44,5 105,5 10,5

25

12

A24-2M12

15,2 28,5 16,0 14,0 44,5 113,0 13,2

25

14

A24-2M14

15,2 28,5 18,0 16,0 44,5 116,5 15,0

25

16

A24-2M16

15,2 28,5 19,0 17,0 44,5 119,0 17,0

25

150

10

A30-2M10

16,7 31,5 13,0 11,0 44,5 113,5 10,5

25

12

A30-2M12

16,7 31,5 16,0 14,0 44,5 119,5 13,2

25

14

A30-2M14

16,7 31,5 18,0 16,0 44,5 123,5 15,0

25

16

A30-2M16

16,7 31,5 19,0 17,0 44,5 125,5 17,0

25

185

10

A37-2M10

19,2 35,5 13,0 11,0 44,5 120,5 10,5

15

12

A37-2M12

19,2 35,5 16,0 14,0 44,5 126,5 13,2

15

14

A37-2M14

19,2 35,5 18,0 16,0 44,5 130,5 15,0

15

16

A37-2M16

19,2 35,5 19,0 17,0 44,5 132,5 17,0

15

240

10

A48-2M10

21,1 39,0 13,0 11,0 44,5 126,5 10,5

15

12

A48-2M12

21,1 39,0 16,0 14,0 44,5 132,5 13,2

15

14

A48-2M14

21,1 39,0 18,0 16,0 44,5 136,5 15,0

15

16

A48-2M16

21,1 39,0 19,0 17,0 44,5 138,5 17,0

15

300

10

A60-2M10

23,7 44,0 13,0 11,0 44,5 133,5 10,5

5

12

A60-2M12

23,7 44,0 20,0 14,0 44,5 143,5 13,2

5

14

A60-2M14

23,7 44,0 22,0 16,0 44,5 147,5 15,0

5

16

A60-2M16

23,7 44,0 22,0 17,0 44,5 148,5 17,0

5

16

A60-2M16/36

23,7 36,0 22,0 17,0 44,5 148,5 17,0

5

400

12

A80-2M12

27,0 51,0 22,0 14,0 44,5 152,5 13,2

5

14

A80-2M14

27,0 51,0 22,0 16,0 44,5 154,5 15,0

5

16

A80-2M16

27,0 51,0 22,0 19,0 44,5 157,5 17,0

5

16

A80-2M16/41

27,0 41,0 22,0 19,0 44,5 157,5 17,0

5

500

12

A100-2M12

30,3 56,5 17,0 14,0 44,5 151,5 13,2

5

16

A100-2M16

30,3 56,5 19,0 19,0 44,5 158,5 17,0

5

630

12

A120-2M12

33,4 61,6 22,0 14,0 44,5 167,5 13,2

1

16

A120-2M16

33,4 61,6 22,0 19,0 44,5 172,5 17,0

1

800

12

A160-2M12

38,0 72,0 20,0 14,0 44,5 176,5 13,2

1

16

A160-2M16

38,0 72,0 22,0 19,0 44,5 183,5 17,0

1

File no. E125401

Not UL approved

*See page 111