23

COPPER TUBE CRIMPING LUGS

for Copper conductors

*Actual conductor section may require a larger lug eg for 120mm

2

size use A30-... lug.

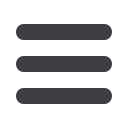

A-M

**See page 111

Cond. Size

sqmm

Ø

Stud

mm

Ref.

D i m e n s i o n s m m

Quantity

Box/Bag

Mechanical

Tools

Hydraulic

Tools

low

stranded flexible*

Ø

i

B

M N L

d

95

70

95

6

A 19-M 6

13,5 25,0 8,0 7,0 50,5 6,4

100/25

TN 120 SE**

B 35-45MDE

B 35-50MDE

HT 45-E

HT 51 B 550E

RH 50 B 500E

HT 81-U RHU 81

HT 120 and tools and heads with 130 kN crimping force

ECW-H3D

RHU 520

8

A 19-M 8

13,5 25,0 9,0 8,0 52,5 8,4

100/25

10

A 19-M 10

13,5 25,0 11,0 10,0 56,5 10,5

100/25

12

A 19-M 12

13,5 25,0 14,0 12,0 61,5 13,2

100/25

14

A 19-M 14

13,5 25,0 16,0 14,0 65,5 15,0

100/25

16

A 19-M 16

13,5 27,0 18,0 16,0 69,5 17,0

100/25

20

A 19-M 20

13,5 29,5 22,0 20,0 77,5 21,0

50/25

120 95

120

8

A 24-M 8

15,2 28,5 9,0 8,0 54,0 8,4

100/25

10

A 24-M 10

15,2 28,5 11,0 10,0 58,0 10,5

100/25

12

A 24-M 12

15,2 28,5 14,0 12,0 63,0 13,2

100/25

14

A 24-M 14

15,2 28,5 16,0 14,0 67,0 15,0

50/25

16

A 24-M 16

15,2 28,5 18,0 16,0 71,0 17,0

50/25

20

A 24-M 20

15,2 30,0 22,0 20,0 79,0 21,0

50/25

150 120

150

8

A 30-M 8

16,7 31,5 13,0 11,0 69,0 8,4

50/25

10

A 30-M 10

16,7 31,5 13,0 11,0 69,0 10,5

50/25

12

A 30-M 12

16,7 31,5 16,0 14,0 75,0 13,2

50/25

14

A 30-M 14

16,7 31,5 18,0 16,0 79,0 15,0

50/25

16

A 30-M 16

16,7 31,5 19,0 17,0 81,0 17,0

50/25

20

A 30-M 20

16,7 31,5 22,0 20,0 87,0 21,0

50/25

185 150

185

8

A 37-M 8

19,2 35,5 13,0 11,0 76,0 8,4

50/25

10

A 37-M 10

19,2 35,5 13,0 11,0 76,0 10,5

40/20

12

A 37-M 12

19,2 35,5 16,0 14,0 82,0 13,2

40/20

14

A 37-M 14

19,2 35,5 18,0 16,0 86,0 15,0

30/15

16

A 37-M 16

19,2 35,5 19,0 17,0 88,0 17,0

30/15

20

A 37-M 20

19,2 35,5 22,0 20,0 94,0 21,0

30/15

240 185

240

8

A 48-M 8

21,1 39,0 13,0 11,0 77,5 8,4

30/15

10

A 48-M 10

21,1 39,0 13,0 11,0 77,5 10,5

30/15

12

A 48-M 12

21,1 39,0 14,0 12,0 79,5 13,2

30/15

14

A 48-M 14

21,1 39,0 18,0 16,0 92,0 15,0

30/15

16

A 48-M 16

21,1 39,0 19,0 17,0 94,0 17,0

30/15

20

A 48-M 20

21,1 39,0 22,0 20,0 100,0 21,0

30/15

300 240

300

10

A 60-M 10

23,7 44,0 20,0 11,0 96,0 10,5

20/10

12

A 60-M 12

23,7 44,0 20,0 14,0 99,0 13,2

20/10

14

A 60-M 14

23,7 44,0 22,0 16,0 103,0 15,0

20/10

16

A 60-M 16

23,7 44,0 22,0 19,0 106,0 17,0

20/10

20

A 60-M 20

23,7 44,0 24,0 23,0 112,0 21,0

20/10

400 300

400

12

A 80-M 12

27,0 51,0 22,0 19,0 113,0 13,2

20/5

14

A 80-M 14

27,0 51,0 22,0 19,0 113,0 15,0

15/5

16

A 80-M 16

27,0 51,0 22,0 19,0 113,0 17,0

15/5

20

A 80-M 20

27,0 51,0 24,0 23,0 119,0 21,0

15/5

500 400

500

16

A 100-M 16

30,3 56,5 22,0 19,0 117,0 17,0

15/1

20

A 100-M 20

30,3 56,5 24,0 23,0 123,0 21,0

15/1

630 500

630

16

A 120-M 16

33,4 61,6 22,0 19,0 128,0 17,0

12/1

20

A 120-M 20

33,4 61,6 24,0 23,0 134,0 21,0

10/1

800 630

16

A 160-M 16

38,0 72,0 24,0 19,0 141,0 17,0

6/1

20

A 160-M 20

38,0 72,0 24,0 23,0 145,0 21,0

6/3

1000 800

16

A 200-M 16

44,0 80,0 24,0 19,0 158,0 17,0

6/1

20

A 200-M 20

44,0 80,0 24,0 23,0 162,0 21,0

6/1

Not UL approved

File no. E125401

Isolated covers made of PVC

for subsequent isolation of

the uninsulated connectors,

see page 33.

o