18

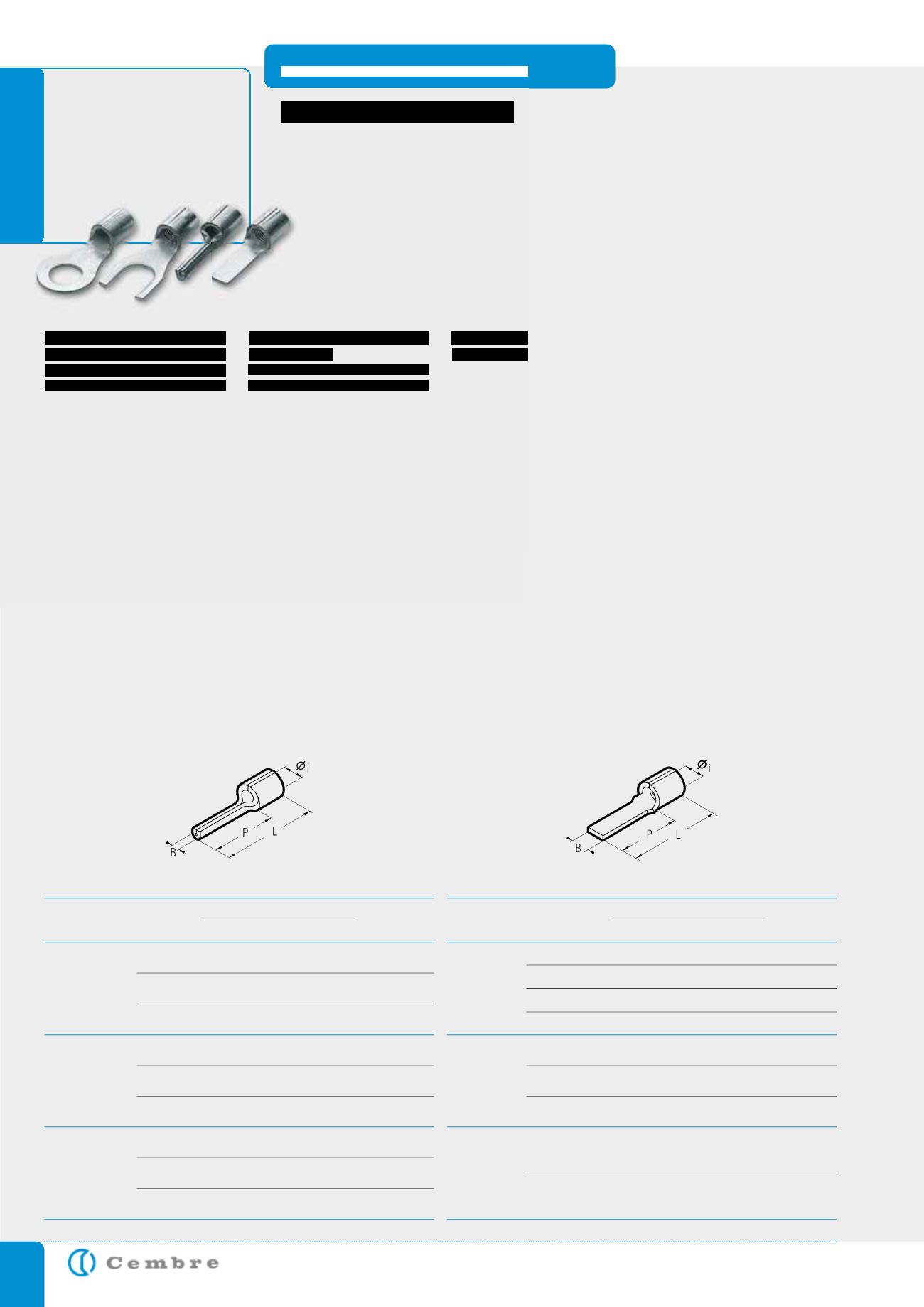

S 1.5-PP 12

1,8

3,0

12,8

17,0

S 1.5-PP 12/1

1,8

3,0

11,3

15,5

S 1.5-PP 12/19

1,8

1,9

13,2

17,4

S 1.5-PP 14

1,8

3,0

14,8

19,0

S 2.5-PP 12

2,4

3,5

12,8

17,0

S 2.5-PP 12/25

2,4

2,5

13,3

17,5

S 2.5-PP 16/25

2,4

2,5

17,2

21,4

S 6-PP 12

3,6

4,0

13,3

19,7

S 6-PP 17

3,6

2,9

19,1

25,5

8.000/100

8.000/100

8.000/100

8.000/100

7.000/100

7.000/100

7.000/100

4.000/100

4.000/100

*Made to order

S range terminals are man-

ufactured from electrolytic

Copper strip and Tin plat-

ed. The seam is brazed to

UNINSULATED TERMINALS

S range - brazed seam

provide uniform mechanical

strength.

The terminal barrel is rifled

to enhance electrical con-

tact and to improve me-

chanical strength.

Recommended crimping

tools are shown on pages

98 to 117, 152.

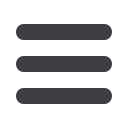

S 1.5-P 8

1,8

1,6

8,0

12,0

S 1.5-P 10

1,8

1,6

10,0

14,0

S 1.5-P 12

1,8

1,6

12,0

16,2

S 2.5-P 8

2,4

1,7

8,0

12,0

S 2.5-P 10

2,4

1,8

10,0

14,0

S 2.5-P 12

2,4

1,8

12,0

16,0

S 6-P 10

3,6

2,2

10,0

16,8

S 6-P 12

3,6

2,2

12,0

19,4

S 6-P 14

3,6

2,2

14,0

21,0

8.000/100

8.000/100

8.000/100

7.000/100

7.000/100

7.000/100

4.000/100

4.000/100

3.500/100

Conductor Size

sqmm

(AWG)

Quantity

Box/Bag

Ø

i

D i m e n s i o n s m m

L

P

B

Ref.

Conductor Size

sqmm

(AWG)

Quantity

Box/Bag

Ø

i

D i m e n s i o n s m m

L

P

B

Ref.

0,25÷1,25

(22÷16)

1,5÷2,5

(16÷14)

4÷6

(12÷10)

0,25÷1,25

(22÷16)

1,5÷2,5

(16÷14)

4÷6

(12÷10)

pin terminals

blade terminals

*

S