210

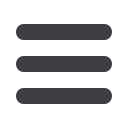

RECOMMENDED TORQUE SETTINGS FOR CABLE GLANDS

Torque ratio values apply to mounting in a threaded

entry and to use with a locknut

Torque ratio values apply to mounting in a threaded

entry and to use with a locknut

THREAD

CABLE GLAND

metallic

non-metallic

M12 x 1,5

M16 x 1,5

M20 x 1,5

M25 x 1,5

M32 x 1,5

M40 x 1,5

M50 x 1,5

M63 x 1,5

6

6

8

8

12

18

18

18

2,7

5,0

7,0

7,5

8,0

8,0

10,0

10,0

torque ratio Nm

, ,

,

to obtain IP68 ingress protection in accordance with EN 50262

CABLE GLAND

Torque ratio values apply to mounting in a threaded

entry and to use with a locknut

THREAD

CABLE GLAND

non-metallic

G1/4”

G3/8”

G1/2”

G3/4”

4

5

6

10

torque ratio Nm

,

to obtain IP68 with reduced tightening force for GAS threads

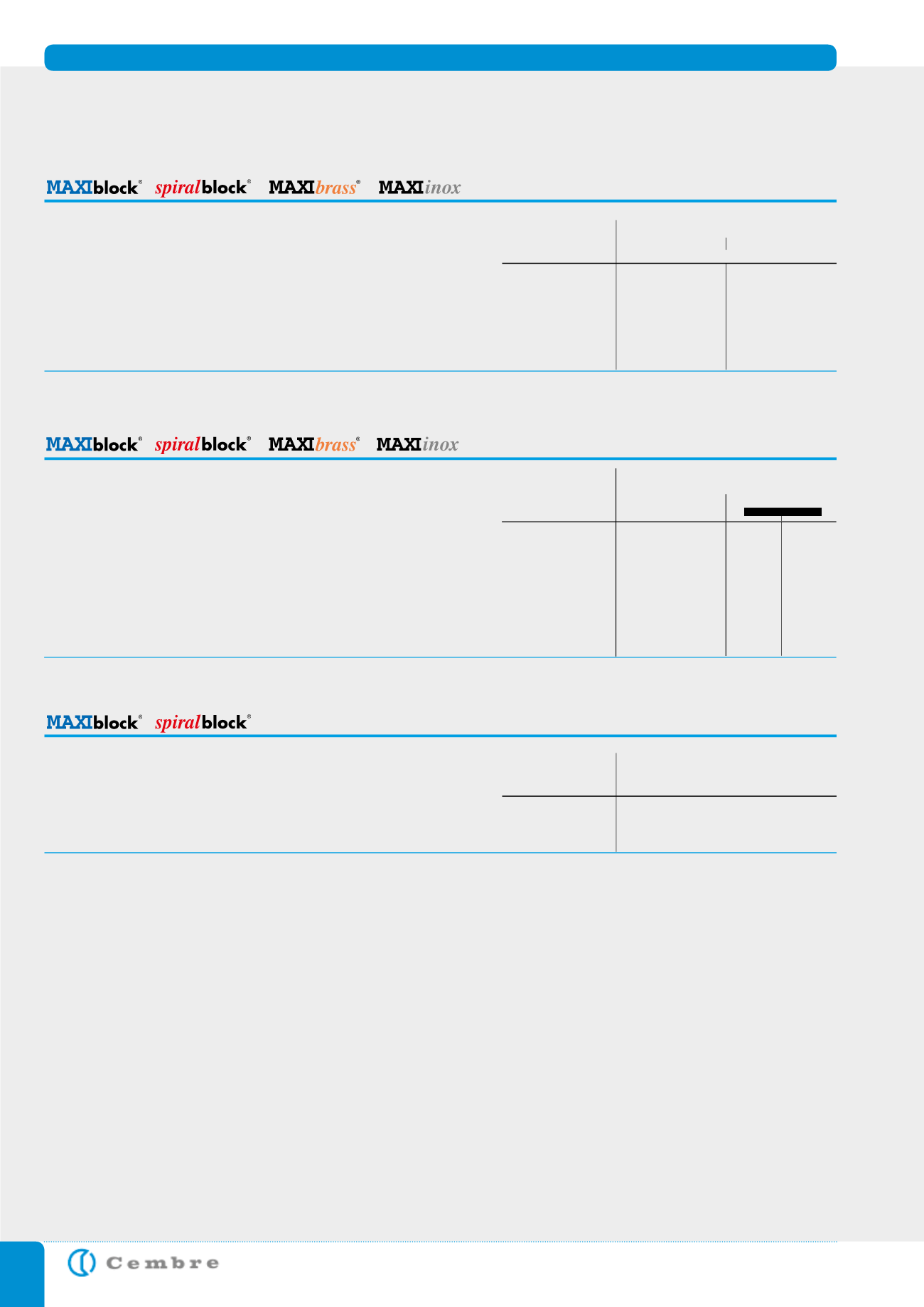

CABLE GLAND

, , ,

to obtain IP68 ingress protection in accordance with DIN VDE for Pg threads

THREAD

CABLE GLAND

CABLE GLAND

metallic

non-metallic series

1900 1910

Pg 7

Pg 9

Pg 11

Pg 13,5

Pg 16

Pg 21

Pg 29

Pg 36

Pg 42

Pg 48

6.25

6.25

6.25

6.25

7.5

10.0

10.0

18.0

18.0

18.0

2.5

3.75

3.75

3.75

5.0

7.5

7.5

7.5

7.5

7.5

torque ratio Nm

2.5

3.75

3.75

3.75

5.0

7.5

7.5

7.5

10.0

10.0

spiral

spiral