204

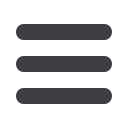

IEC 60228 : 2004 - 11 CONDUCTOR TABLES

CLASS 1:

SOLID CONDUCTORS FOR SINGLE-CORE AND MULTI-CORE CABLES

Nominal cross-sectional

[mm

2

]

Maximum resistance of conductor at 20 °C

Circular, annealed Copper conductors

Aluminium and Aluminium alloy conductors,

circular or shaped

c

[ohm/km]

Plain [ohm/km]

Metal [ohm/km]

0,5

36

36,7

-

0,75

24,5

24,8

-

1

18,1

18,2

-

1,5

12,1

12,2

-

2,5

7,41

7,56

-

4

4,61

4,70

-

6

3,08

3,11

-

10

1,83

1,84

3,08

a

16

1,15

1,16

1,91

a

25

0,727

b

-

1,20

a

35

0,524

b

-

0,868

a

50

0,387

b

-

0,641

70

0,268

b

-

0,443

95

0,193

b

-

0,320

d

120

0,153

b

-

0,253

d

150

0,124

b

-

0,206

d

185

0,101

b

-

0,164

d

240

0,0775

b

-

0,125

d

300

0,0620

b

-

0,100

d

400

0,0465

b

-

0,0778

500

-

-

0,0605

630

-

-

0,0469

800

-

-

0,0367

1000

-

-

0,0291

1200

-

-

0,0247

a

Aluminium conductors 10 mm

2

to 35 mm

2

circular only

b

Solid Copper conductors having nominal cross-sectional area of 25 mm

2

and above are for particular types of cable, e.g. mineral insulated, and not for general purposes.

c

For solid Aluminium alloy conductors, having the same nominal cross-sectional area as an Aluminium conductor, the resistance value given in the table should be multiplied by a factor of

1,162 unless otherwise agreed between the manufacturer and the purchaser.

d

For single core cables, four sectoral shaped conductors may be assembled into a single circular conductor. The maximum resistance of the assembled conductor shall be 25% of that of the

individual component conductors.

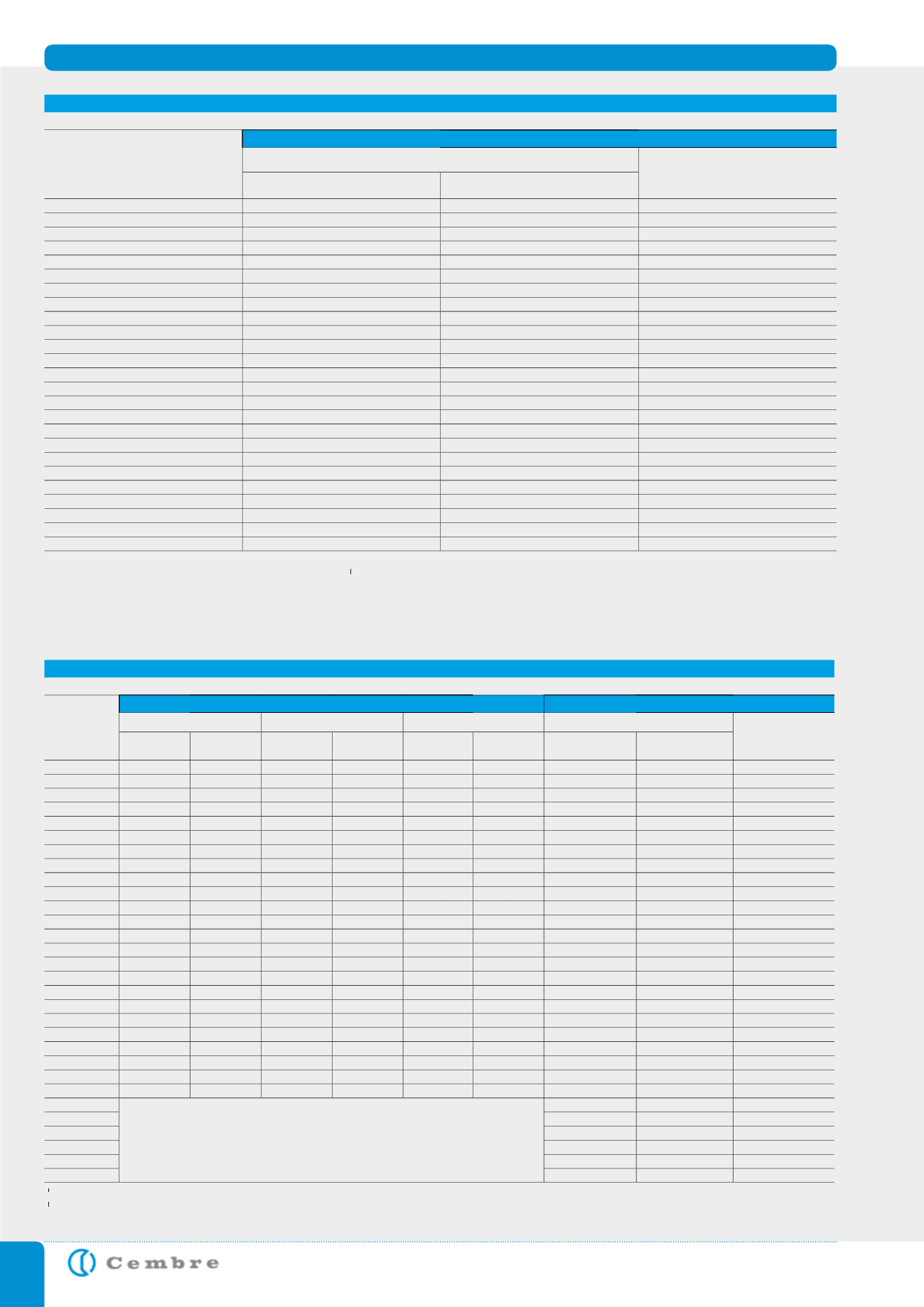

CLASS 2:

STRANDED CONDUCTORS FOR SINGLE-CORE AND MULTI-CORE CABLES

Nominal cross-

sectional area

[mm

2

]

Minimum number of wires in the conductor

Maximum resistance of conductor at 20 °C

Circular

Circular compacted

Shaped

Annealed Copper conductor

Aluminium or Aluminium

alloy conductor

c

[ohm/

km]

Cu

Al

Cu

Al

Cu

Al

Plain wires [ohm/km] Metal-coated wires

[ohm/km]

0,5

7

-

-

-

-

-

36,0

36,7

-

0,75

7

-

-

-

-

-

24,5

24,8

-

1,0

7

-

-

-

-

-

18,1

18,2

-

1,5

7

-

6

-

-

-

12,1

12,2

-

2,5

7

-

6

-

-

-

7,41

7,56

-

4

7

-

6

-

-

-

4,61

4,70

-

6

7

-

6

-

-

-

3,08

3,11

-

10

7

7

6

6

-

-

1,83

1,84

3,08

16

7

7

6

6

-

-

1,15

1,16

1,91

25

7

7

6

6

6

6

0,727

0,734

1,20

35

7

7

6

6

6

6

0,524

0,529

0,868

50

19

19

6

6

6

6

0,387

0,391

0,641

70

19

19

12

12

12

12

0,268

0,270

0,443

95

19

19

15

15

15

15

0,193

0,195

0,320

120

37

37

18

15

18

15

0,153

0,154

0,253

150

37

37

18

15

18

15

0,124

0,126

0,206

185

37

37

30

30

30

30

0,0991

0,100

0,164

240

61

61

34

30

34

30

0,0754

0,0762

0,125

300

61

61

34

30

34

30

0,0601

0,0607

0,100

400

61

61

53

53

53

53

0,0470

0,0475

0,0778

500

61

61

53

53

53

53

0,0366

0,0369

0,0605

630

91

91

53

53

53

53

0,0283

0,0286

0,0469

800

91

91

53

53

-

-

0,0221

0,0224

0,0367

1000

91

91

53

53

-

-

0,0176

0,0177

0,0291

1200

b

b

b

b

b

b

0,0151

0,0151

0,0247

1400

a

0,0129

0,0129

0,0212

1600

0,0113

0,0113

0,0186

1800

a

0,0101

0,0101

0,0165

2000

0,0090

0,0090

0,0149

2500

0,0072

0,0072

0,0127

a

Non-preferred sizes. Other non-preferred sizes are recognized for some specialized applications but are not within the scope of this standard.

b

The minimum number of wires for these sizes is not specified. These sizes may be constructed from 4, 5 or 6 equal segments (Milliken).

c

For stranded Aluminium alloy conductors having the same nominal cross-sectional area as an Aluminium conductor the resistance value should be agreed between the manufacturer and the purchaser.