209

FLAMMABILITY TEST FOR PRODUCTS AND MATERIALS

CHARACTERISTIC

FEATURES

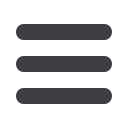

Glow-wire

4 mm in

diameter

Any sign of flame starting must stop

within 30 sec. of removing

the glowing wire

TEST TEMPERATURE

• 650° for materials which do not

support parts under tension

• 750° for materials which support

parts under tension of moving

sockets and plugs

• 850° for materials which support

parts under tension of fixed

sockets and switches

Check that abnormal heating produced

by overcurrent and bad contacts does

not compromise the safety of the

insulating material.

Lighting test. The wire is pressed

against the sample using force and

penetrates up to 7 mm.

IEC 695-2-1

CEI 50-11

DIN VDE 0471-2-1

Wire applied

for 30 seconds

Flame

extinction

time

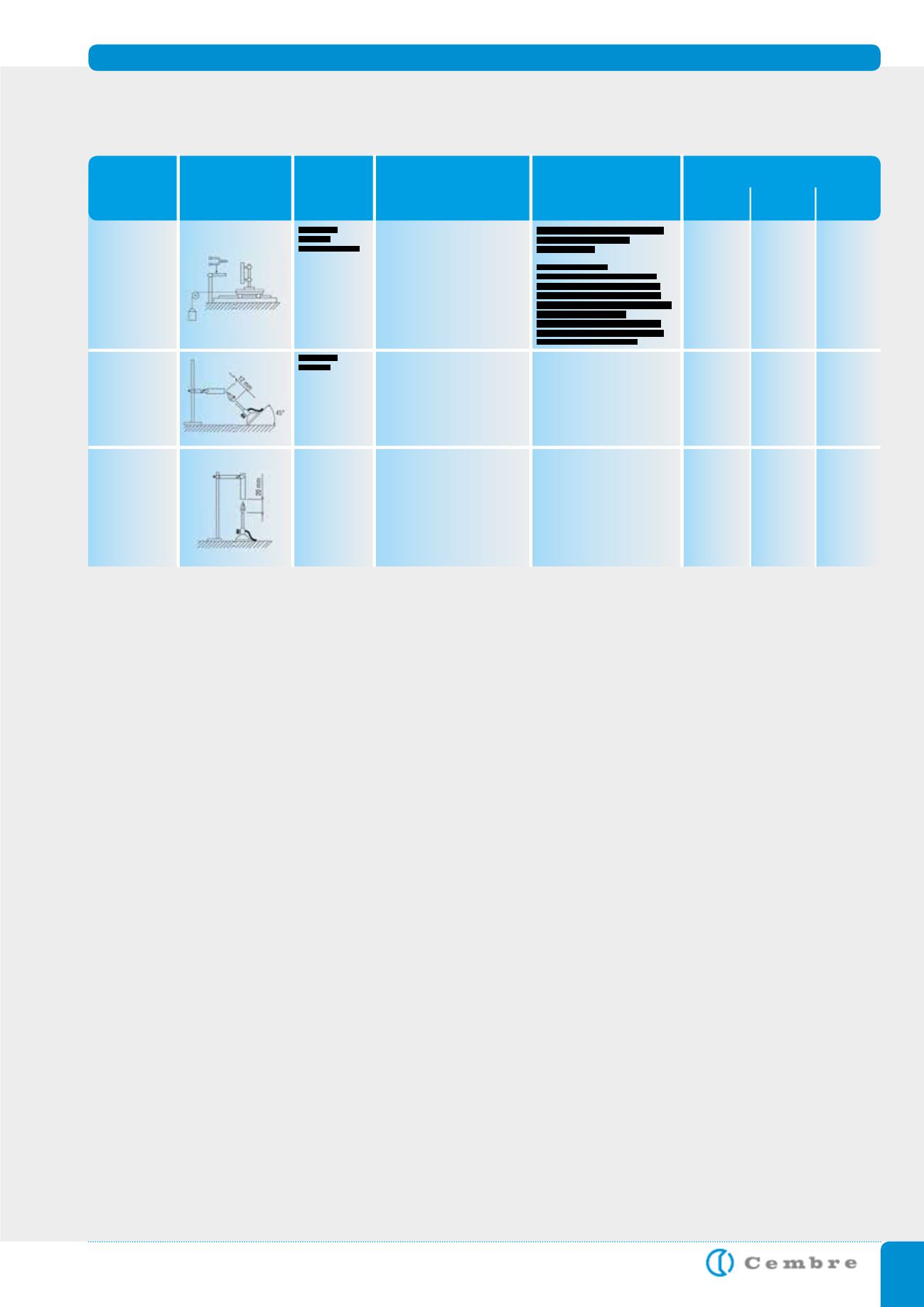

NEEDLE

FLAME

Bunsen burner

flame

• the sample does not catch fire

• the flame and incandescent

particles do not spread the fire

• combustion lasts less than 30

seconds

Simulates the effect small flames have

which may occur due to internal faults

of products in order to judge the fire

risk.

IEC 695-2-1

CEI 50-11

Flame applied

for (Ta) 5, 10,

20, 30, 60,

120 sec.

According to

particular

standards

The degree of

severity: flame

application time

(Ta)

UL

(UNDERWRITER’

LABORATORIES)

Bunsen burner

flame

• V0 if the sample burns for less than

5 sec. before going out.

• V1 if it burns for less than 25 sec.

• V2 if it burns for less than 25 sec.

With incandescent drops

• HB if it burns for more than 25 sec.

(horizontal sample and burning

speed less than 38 mm per minute)

Comparable to ASTM D-635

Measuring of time the sample

continues to burn after the

direct flame has been removed

UL 94

Flame

applied for 10

seconds twice

following

Length of

combustion

TYPE OF TEST

TEST

EQUIPMENT

COMPLIANCE

WITH

STANDARDS

OBJECTIVE

OF TEST

TEST

RESULTS

heat

source

length of

test

characteristic

features

TEST CONDITIONS