Furse, Wilford Road, Nottingham, NG2 1EB • Tel: +44 (0)115 964 3700 • Email:

enquiry@furse.com• Web:

www.furse.comTSC-0912 - 09.10.12

BS EN/IEC 62305-4

Guide to BS EN/IEC 62305

Indeed, as per BS EN/IEC 62305-3, an LPS system can no

longer be fitted without lightning current or

equipotential bonding SPDs to incoming metallic

services that have “live cores” - such as power and

telecoms cables - which cannot be directly bonded

to earth. Such SPDs are required to protect against

the risk of loss of human life by preventing

dangerous sparking that could present fire or electric

shock hazards.

Lightning current or equipotential bonding SPDs are

also used on overhead service lines feeding the

structure that are at risk from a direct strike. However,

the use of these SPDs alone “provides no effective

protection against failure of sensitive electrical or

electronic systems”, to quote BS EN/IEC 62305 part 4,

which is specifically dedicated to the protection of

electrical and electronic systems within structures.

Lightning current SPDs form one part of a coordinated

set of SPDs that include overvoltage SPDs - which are

needed in total to effectively protect sensitive

electrical and electronic systems from both lightning

and switching transients.

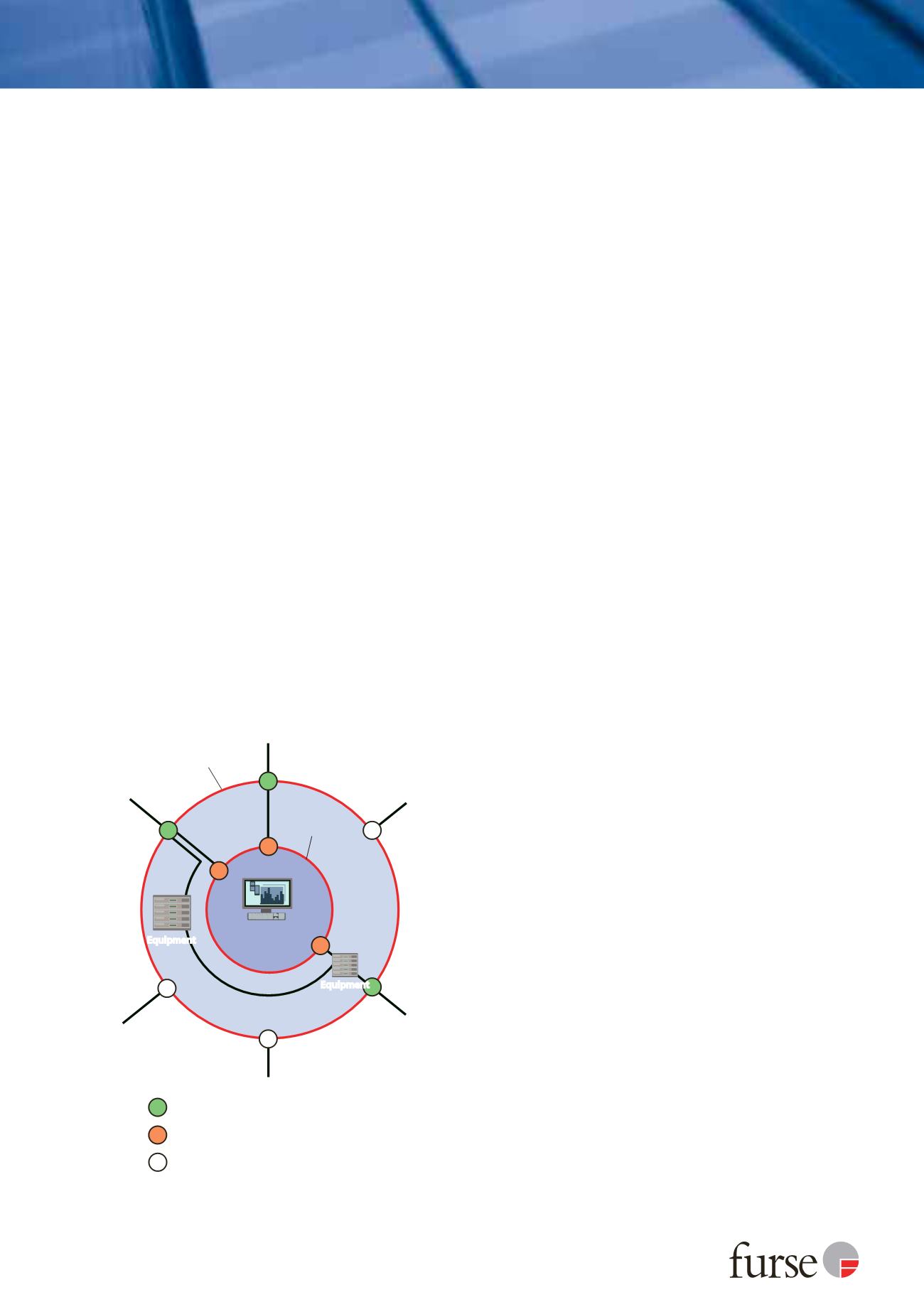

Lightning Protection Zones (LPZs)

Whilst BS 6651 recognised a concept of zoning

in Annex C (Location Categories A, B and C),

BS EN/IEC 62305-4 defines the concept of Lightning

Protection Zones (LPZs). Figure 22 illustrates the basic

LPZ concept defined by protection measures against

LEMP as detailed within part 4.

Boundary

of LPZ 2

(shielded room)

Boundary

of LPZ 1

(LPS)

Antenna

Electrical

power line

Water pipe

Gas pipe

Telecoms

line

Mast or

railing

LPZ 2

B

B

B

B

LPZ 1

Critical

equipment

Equipment

SPD 1/2 - Overvoltage protection

Connected service directly bonded

SPD 0/1 - Lightning current protection

Equipment

LPZ

0

Figure 22: Basic LPZ concept - BS EN/IEC 62305-4

Within a structure a series of LPZs are created to have,

or identified as already having, successively less

exposure to the effects of lightning.

Successive zones use a combination of bonding,

shielding and coordinated SPDs to achieve a significant

reduction in LEMP severity, from conducted surge

currents and transient overvoltages, as well as radiated

magnetic field effects. Designers coordinate these

levels so that the more sensitive equipment is sited in

the more protected zones.

The LPZs can be split into two categories - 2 external

zones (LPZ

0

A

, LPZ

0

B

) and usually 2 internal zones

(LPZ 1, 2) although further zones can be introduced for

a further reduction of the electromagnetic field and

lightning current if required.

External zones

LPZ

0

A

is the area subject to direct lightning strokes

and therefore may have to carry up to the full

lightning current.

This is typically the roof area of a structure. The full

electromagnetic field occurs here.

LPZ

0

B

is the area not subject to direct lightning strokes

and is typically the sidewalls of a structure.

However the full electromagnetic field still occurs here

and conducted partial lightning currents and switching

surges can occur here.

Internal zones

LPZ 1 is the internal area that is subject to partial

lightning currents. The conducted lightning currents

and/or switching surges are reduced compared with

the external zones LPZ

0

A

, LPZ

0

B

.

This is typically the area where services enter the

structure or where the main power switchboard is

located.

LPZ 2 is an internal area that is further located inside

the structure where the remnants of lightning impulse

currents and/or switching surges are reduced compared

with LPZ 1.

This is typically a screened room or, for mains power, at

the sub-distribution board area.

Protection levels within a zone must be coordinated

with the immunity characteristics of the equipment to

be protected, i.e., the more sensitive the equipment,

the more protected the zone required.

The existing fabric and layout of a building may make

readily apparent zones, or LPZ techniques may have to

be applied to create the required zones.