TSC-0912 - 09.10.12

Furse, Wilford Road, Nottingham, NG2 1EB • Tel: +44 (0)115 964 3700 • Email:

enquiry@furse.com• Web:

www.furse.comConductors

Copper conductor ratings

For below ground earthing applications we produce a large range of bare copper, tape and stranded conductors thus

offering the designer of the system the correctly rated conductor without the need to oversize.

The following conductor ratings are based upon the recommendations of BS 7430 with an initial conductor

temperature of 30 °C and a maximum temperature of 250 °C.

Conductor

size

C.S.A.

(mm

2

)

kA for

1 sec

kA for

3 sec

Conductor

size

C.S.A.

(mm

2

)

kA for

1 sec

kA for

3 sec

12.5 x 1.5 mm

18.75

3.3

1.9

31 x 6 mm

186

32.7

18.9

12.5 x 3 mm

37.5

6.6

3.8

38 x 3 mm

114

20.1

11.6

20 x 1.5 mm

30

5.3

3.0

38 x 5 mm

190

33.4

19.3

20 x 3 mm

60

10.6

6.1

38 x 6 mm

228

40.1

23.2

25 x 1.5 mm

37.5

6.6

3.8

40 x 3 mm

120

21.1

12.2

25 x 3 mm

75

13.2

7.6

40 x 4 mm

160

28.2

16.3

25 x 2 mm

50

8.8

5.1

40 x 5 mm

200

35.2

20.3

25 x 4 mm

100

17.6

10.2

40 x 6 mm

240

42.2

24.4

25 x 6 mm

150

26.4

15.2

40 x 6.3 mm

252

44.4

25.6

30 x 2 mm

60

10.6

6.1

50 x 3 mm

150

26.4

15.2

30 x 3 mm

90

15.8

9.1

50 x 4 mm

200

35.2

20.3

30 x 4 mm

120

21.1

12.2

50 x 5 mm

250

44.0

25.4

30 x 5 mm

150

26.4

15.2

50 x 6 mm

300

52.8

30.5

31 x 3 mm

93

16.4

9.5

50 x 6.3 mm

315

55.4

32.0

31.5 x 4 mm

126

22.2

12.8

50 x 7 mm

350

61.6

35.5

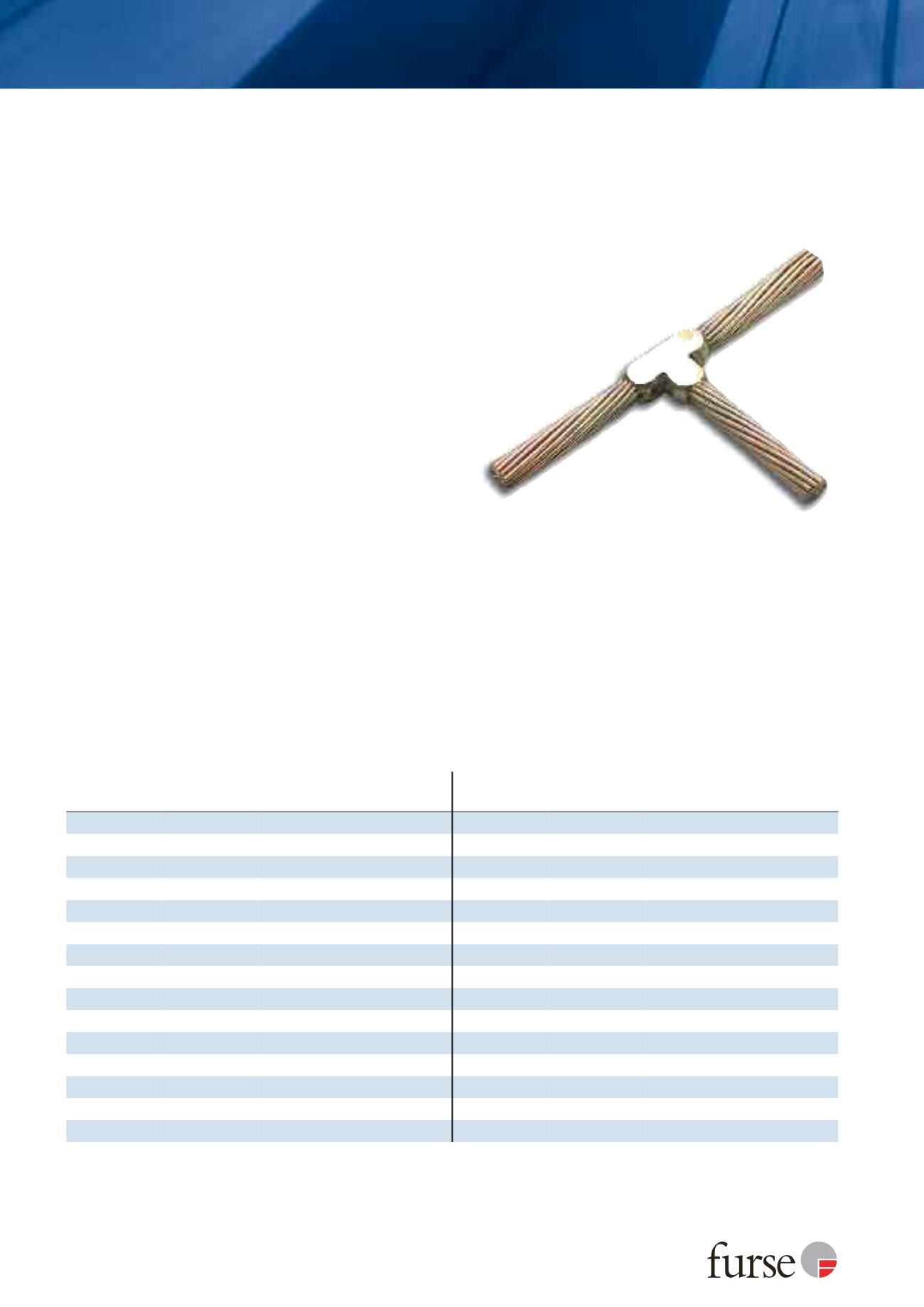

Conductors for earthing systems

Furse earthing conductors form an integral part of the single earthing arrangement for a structure, whether they

provide the means of connection to the final earth electrode (earth rod or plate), or whether they comprise the earth

electrode itself (through an earth grid or ring earth arrangement).

An earth conductor must be capable of carrying the maximum expected earth fault current and

leakage current likely to occur at a structure.

The size or minimum cross-sectional area of the conductor must

therefore be gauged in accordance with these criteria.

A good earth conductor must also:

be able to withstand mechanical damage

be compatible with the material of the earth electrode, and

resist the corrosive effect of local soil conditions

Furse conductors effectively meet these requirements

and are available in a range of sizes to meet differing

current ratings (see table below).

Copper conductor is recommended as, following

BS 7430, aluminium should not be installed in contact

with soil, nor in damp areas, and it should not be used

to make the final connection to an earth electrode.