Furse, Wilford Road, Nottingham, NG2 1EB • Tel: +44 (0)115 964 3700 • Email:

enquiry@furse.com• Web:

www.furse.comTSC-0912 - 09.10.12

Introduction

Lightning protection

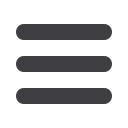

Lightning protection products shown in this catalogue include where appropriate a range of quick reference icons

to define their conductor compatibility, installation requirements and their testing standard.

These icons, as well as a sample product page, are shown below.

The icon bar above each product defines the appropriate main conductor system to which the product can

be connected.

Therefore, where items , ,

are highlighted in full, the product is suitable for connection to the main

conductor system shown (see below).

Icons defining installation requirements and product testing feature under the product text.

These are shown in the example below, and on product pages as - testing standard,

- fixings required, and

- torque setting.

1 2 3

4

5

6

1

Component is suitable for

use with flat tape conductor

in sizes shown

2

Component is suitable for

use with solid circular

conductor in sizes shown

3

Component is suitable for

use with stranded conductor

in sizes shown

4

Component has been

tested to the quoted

standard (BS/BS EN/IEC/UL)

5

Component requires

additional fixings as

advised to enable

installation

6

Component should be

tightened to the torque

setting advised

Conductor

size

Material

Weight Part

each No.

25x3mm

Copper

0.12 kg

CT105-H

†

25x6mm

Copper

0.30 kg

CT110-H

†

50 x6mm

Copper

0.60 kg

CT115-H

†

25 x3mm

Aluminium

0.06 kg

CT005-H

25x6mm

Aluminium

0.17 kg

CT010-H

Manufactured from high quality copper and aluminium alloys. Simple

to install, providing an effective low resistance connection between

overlapping tapes to allow cross, tee, through and right angle joints to

be formed.

BS EN 50164-1 Class H

†

UL96 (CT105H, CT110-H, CT115-H)

Fix using countersunk wood screws 1

1

⁄

2

” No. 10 or M6 (Part no.

SW005

or

SW105

) and wall plugs (Part no.

PS305

) - see Accessories

page 72.

Tightening torque 5 Nm

Conductor

size

Material

Weight Part

each No.

25x3mm

Copper

0.09 kg

CX105-H

25 x3mm

Aluminium

0.03 kg

CX005-H

Manufactured from high quality copper and aluminium alloys. Simple to

install, providing an effective low resistance connection between

overlapping tapes to allow cross joints to be formed.

Crossover clamp

BS EN 50164-1 Class H

Fix using countersunk wood screws 1

1

⁄

2

” No. 10 or M6 (Part no.

SW005

or

SW105

) and wall plugs (Part no.

PS305

) - see Accessories

page 72.

Tightening torque 5 Nm

Square clamp

NEW

CT105-H

CX105-H

1

4

5

6

2

3

Special component design and manufacture

For the vast majority of installations, the standard range of conductors

and lightning protection components is highly suitable for completing a

lightning protection system. On occasion however, an installation may

include a special requirement needing a non-standard component.

Our technical services team is adept at developing and designing special

components to customer needs, which on approval can be manufactured

in the quantity specified for the project.

If you consider your lightning protection system will require development

of a special component (e.g. new sizing or revised design), please do not

hesitate to contact us to discuss your needs.

Product selection