PowerSafe – Commercial & Industrial

55

Protecting electrical installations

against transient overvoltages

using SPDs

British Standard BS EN 62305:2011 Protection against

lightning and the IET Wiring Regulations 17th Edition, BS

7671:2008 (+A1:2011) define requirements for selection and

installation of SPDs to protect against transient overvoltage

risk.

SPDs are recommended as follows, according to the

installation:

s ,IGHTNING CURRENT EQUIPOTENTIAL BONDING 30$S 4YPE

or Combined Type 1+2) to protect against flashover –

required on incoming/outgoing metallic service lines

which have ‘live cores’ if a building includes an external

LPS or overhead service lines at risk from a direct

lightning strike

s 4RANSIENT OVERVOLTAGE 30$S 4YPE 4YPE OR #OMBINED

Type 2+3) to protect against transient overvoltages

caused by indirect lightning strikes and switching events

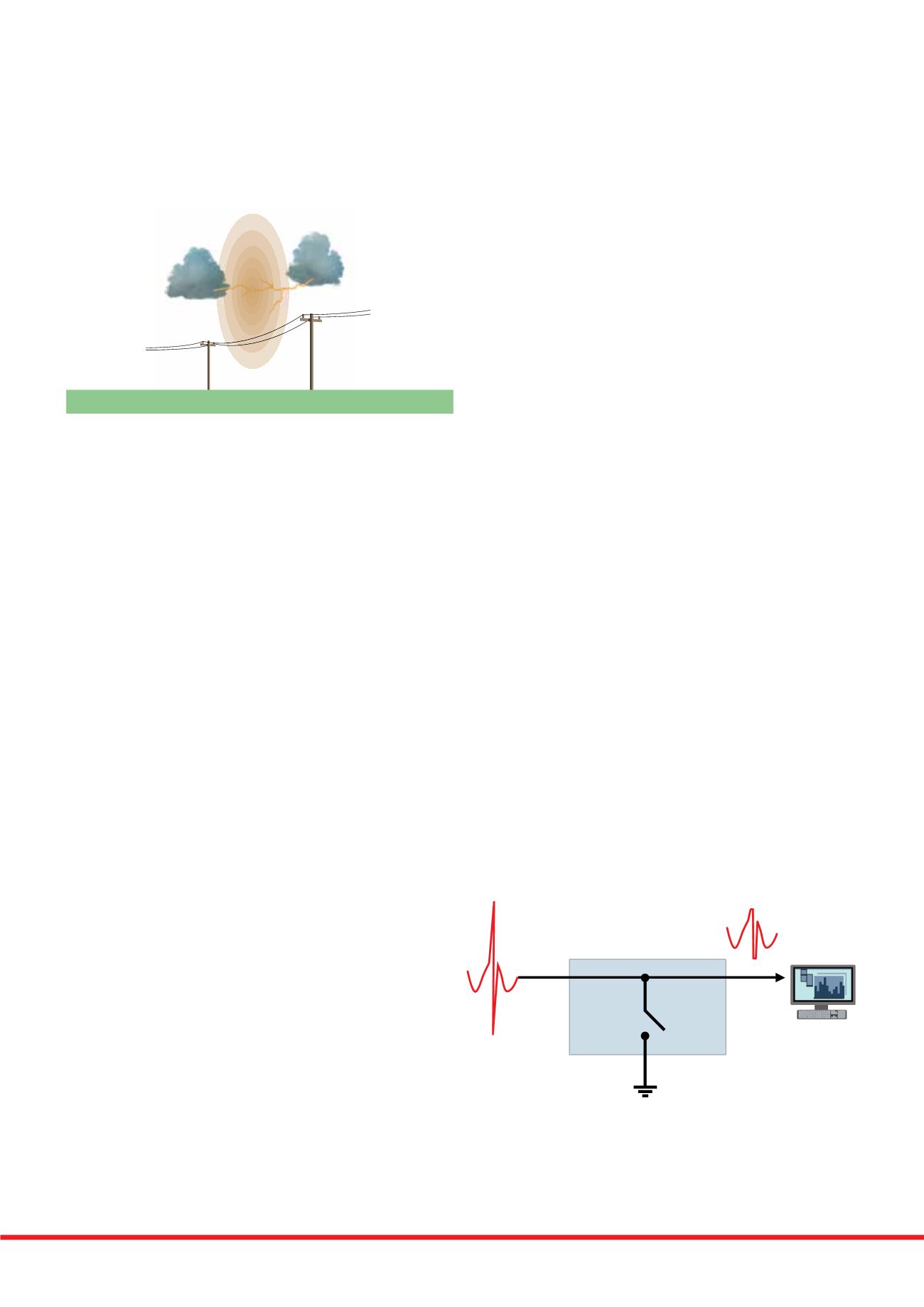

For either Type, the function of the SPD is to limit transient

overvoltages to a safe level by diverting excess energy either

to earth or away from the sensitive and critical electrical

equipment (see Figure 4).

Transient

overvoltage

SPD

Surge

(close)

Normal

(open)

Equipment

Figure 3: Inductive coupling

Lightning discharges give rise to an electromagnetic field. If metallic

service lines pass through this electromagnetic field a voltage will be picked

up by, or induced onto, the lines.

Transient overvoltages can therefore enter a structure via these

connected metallic services, and damage electronic systems as the

overvoltage attempts to flow to earth.

BS 7671 and BS EN 62305 make clear however that

installation of lightning current/equipotential bonding SPDs

alone provides no effective protection against failure of

sensitive and critical electronic systems.

Transient overvoltage SPDs should be installed downstream

at sub-distribution boards and at critical electrical equipment

to ensure effective protection.

BS 7671 gives guidance, through Sections 443 & 534, on

transient overvoltage protection of AC power supplies to

ensure satisfactory electrical installation, which includes:

s 30$ INSTALLATION AS CLOSE AS PRACTICABLE TO THE ORIGIN

of the supply, generally in the main distribution board,

after the meter – to counter incoming high level transient

overvoltages at the service entrance

s 30$ INSTALLATION AS CLOSE AS PRACTICABLE TO TERMINAL

equipment (sub-distribution level or local to critical

equipment) – to cover risk from voltage oscillations within

the electrical system

s 3HORT CONNECTING LEADS IDEALLY LESS THAN M BETWEEN

the SPD and the conductor – to reduce risk of additive

inductive voltages after the SPD

s 30$ COORDINATION THROUGHOUT THE INSTALLATION

The Havells PowerSafe solution with Furse

®

SPD kit has

been specifically designed to achieve all these requirements.

Furse

®

SPD kits are available for all Havells PowerSafe main

distribution and sub-distribution boards, and are supplied

with a standard cable loom, to ensure the shortest possible

lead length between the SPD and distribution board.