6/14

Functions

(

continued)

Software

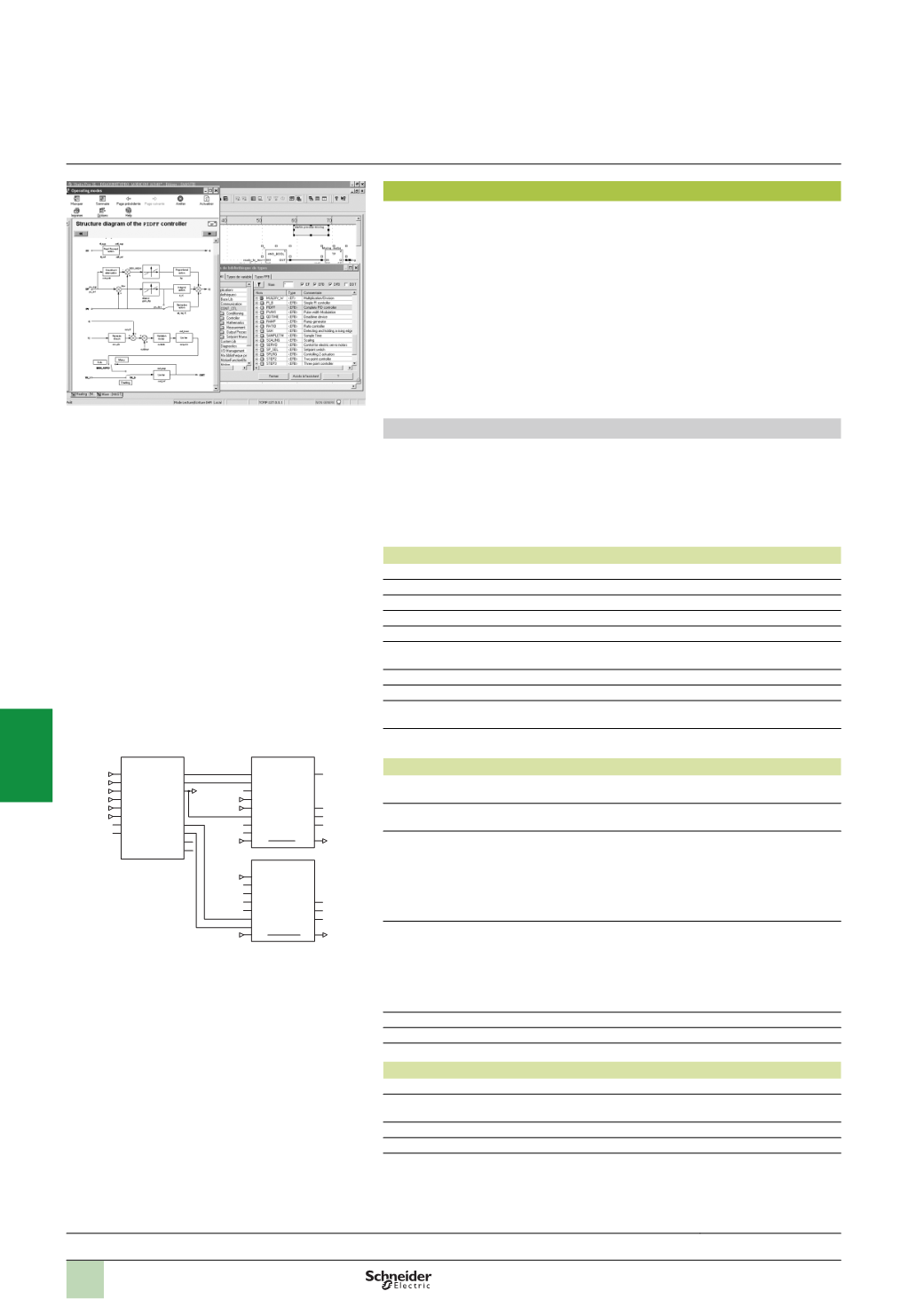

Unity Pro software

Small/Medium/Large/Extra Large

Programmable process control

Process control in machines

Unity Pro contains

CONT_CTL,

a library of 36 function blocks used to create control

loops for machine control.

All requirements for closed loop control functions in machines are adequately met by

Modicon M340, Premium and Quantum platforms thanks to the wealth of functions in

the library and the flexibility with which function blocks can be linked together

through programming. This solution therefore eliminates the need for external

controllers and simplifies the overall control architecture of the machine, as well as

its design, roll-out and operation.

The EFs or EFBs can be used in all Unity Pro languages (LD, ST, IL and FBD). FBD

is particularly suitable for accessing control processing operations in Unity Pro

through its wizard for entering and viewing parameters and function block variables.

CONT_CTL library functions

The library consists of five function families:

b

Input data conditioning

b

Controllers

b

Mathematical functions

b

Process value processing

b

Output value processing

Input data conditioning

DTIME

Pure time delay

INTEGRATOR

Integrator with limiting

LAG_FILTER

First order time lag

LDLG

Lead/lag function with smoothing

LEAD

Lead function with smoothing

MFLOW

Mass flow calculation based on the measurement of differential

pressure or flow speed with pressure and temperature compensation

QDTIME

Dead time term

SCALING

Scaling

TOTALIZER

Integrator (typically of flow) until a limit (typically a volume) is

reached, with automatic reset

VEL_LIM

Velocity limiter, with manipulated variable limiting

Controllers

PI_B

Basic PI controller: PI algorithm with a mixed structure

(

series/parallel)

PIDFF

Complete PID controller: PID algorithm with a parallel or mixed

structure (series/parallel)

AUTOTUNE

Automatic tuner setting for the PIDFF (complete PID) controller or

the PI_B (simple PI) controller

v

Identification using Ziegler Nichols type method

v

Modelling based on first order process

v

Building of control parameters with criterion for prioritizing

either the reaction time to disturbance (dynamic) or the stability of

the process

IMC

Model-based controller. The model is a first order model with

delay. This corrector is useful:

v

When there are serious delays compared with the main time

constant of the process; this scenario cannot be satisfactorily

resolved by standard PID process control

v

For regulating a non-linear process

IMC can handle any stable and aperiodic process of any order.

SAMPLETM

Control of controller startup and sampling

STEP2

Simple two-position controller

STEP3

Three-position controller for temperature regulation

Mathematical functions

COMP_DB

Comparison of two values, with dead zone and hysteresis

K_SQRT

Square root, with weighting and threshold, useful for linearization

of flow measurements

MULDIV_W

Weighted multiplication/division of 3 numerical values

SUM_W

Weighted summing of 3 numerical values

CONT_CTL, programmable process control integrated in

Unity Pro

AUTOTUNE

PV

SP

RCPY

START

PREV

PARA

TR_I

TR_S

PV_O

SP_O

PARA_C

TRI

TRS

INFO

STATUS

TT18_PV

TT18_SP

TC18_OUT

TC18_START

TC18_PREV

TC_PARA

TC18_PARA

TC18_OUT

1

TC2_OUT

TC2_OUT

TC18_OUT

PV

SP

PARA

TR_I

TR_S

PIDFF

FF

RCPY

MAN_AUTO

OUT

OUT

OUTD

MA_O

INFO

STATUT

TC2_OUT

MS

TC18_OUT

IN

PARA

TR_I

TR_S

FORC

MA_FORC

MAN_AUTO

OUT

OUT

OUTD

MA_O

STATUT

Example: PID controller with MS manual control

Selection guide:

page 6/2

2

1

3

4

5

6

7

8

9

10