5/25

Functions

Modicon Premium automation

platform

Transparent Ready, system approach

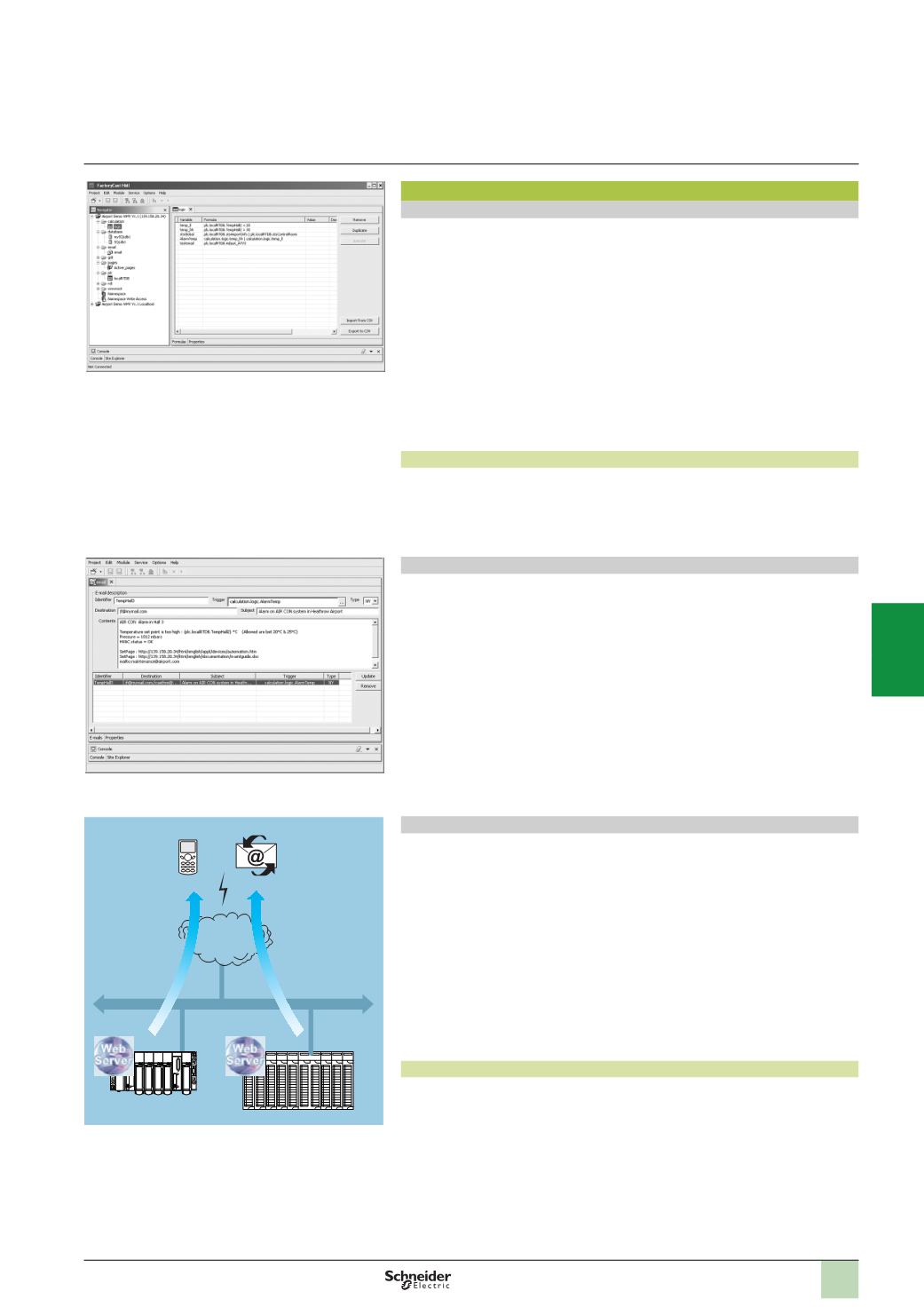

FactoryCast HMI active Web services

Specialized HMI services

Real-time database

With an internal architecture similar to that of an HMI/SCADA system, FactoryCast

HMI modules manage their own variables database in real time, independently of the

PLC program. It is this variables database that is used to execute various functions,

including internal processing, archiving, alarms, e-mail, etc.

Variables in this real-time database are updated using the PLC's data acquisition

service.

This service becomes operational once the following parameters have been set in

the FactoryCast HMI software:

b

Direct import of PLC variables/symbol databases (no double entry)

b

Definition of the acquisition frequency (period at which this variable is updated)

Note:

A FactoryCast HMI application running in a Premium configured FactoryCast HMI module

can access all the PLC variables in the architecture transparently on the network (X-Way/Uni-TE

transparent protocols).

Characteristics

b

Maximum number of I/O variables per application: 1000 variables from PLCs

b

Maximum number of internal variables per application: 100

b

Acquisition frequency: 500 ms minimum

Calculation functions

The FactoryCast HMI server can carry out various arithmetic or logical operations on

a combination of variables from the HMI database. These calculations include, for

example, scaling, formatting, logic processing for event triggering, etc.

This calculation function is operational from the local HMI database, independently

of the PLC processor, and is in the form of spreadsheets where the formulas are

defined in cells.

The spreadsheets are interpreted and processed by the server. The result of each

formula is associated with a new internal variable. The processing of each

spreadsheet is initiated by a trigger.

E-mail transmission

The FactoryCast HMI module can, on a specific event, send e-mails completely

autonomously to a predefined list of e-mail addresses. This function is executed

independently of the PLC program.

The event that triggers the e-mail may be associated with the following:

b

A PLC variable (I/O, internal variable)

b

An alarm, a threshold overshoot

b

Amachine or process state

b

An operator action, etc.

When an e-mail is sent it passes via an SMTP (Simple Mail Transfer Protocol)

server. This server receives the e-mail and waits for the recipient to acknowledge it.

The e-mail service is compatible with all SMTP servers. A return address can be

defined should delivery to the destination address fail.

Characteristics

b

Configuration of the SMTP server: compatible with all SMTP servers

b

Maximum number of e-mails: 100

b

Contents of e-mail messages: free text with embedded dynamic variable values

(

from the PLC) and hyperlinks (unlimited)

E-mail transmission

Premium

Quantum

SMS

Internet

Web server

Web server

Real-time database

Calculation function

2

1

3

4

5

6

7

8

9

10