4/59

Functions

(

continued)

Management of supervision transparency (SCADA)

Transparency of communication with level 2 (supervisor, third-party device, etc.)

when the Primary PLC is switched to the Standby PLC by another pair of Ethernet

Modbus/TCP

TSX ETY 4103/5103

modules. Therefore, communication with a

redundant architecture is similar to that with a standard architecture. This

transparency is the result of the automatic “IP” and “IP + 1” address assignment

mechanism.

This transparency also applies with Modbus when using the

TSX SCP 114

PCMCIA

card (Modbus slave protocol in RS 485) inserted in the

TSX SCY 21601

communication

module (automatic “n” and “n + 1” address assignment mechanism).

Memory space

All the memory space reserved for the application program and the data is managed

by the Hot Standby system with Unity Pro software. With an embedded 192 KB or

440

KB RAM memory (depending on the model), the RAM memory for the

TSX H57 24M

and

TSX H57 44M

processors, dedicated to Hot Standby

applications, can be increased for the application program to 768 KB or 2048 KB

(

depending on the model) by the addition of a

PCMCIA

memory card.

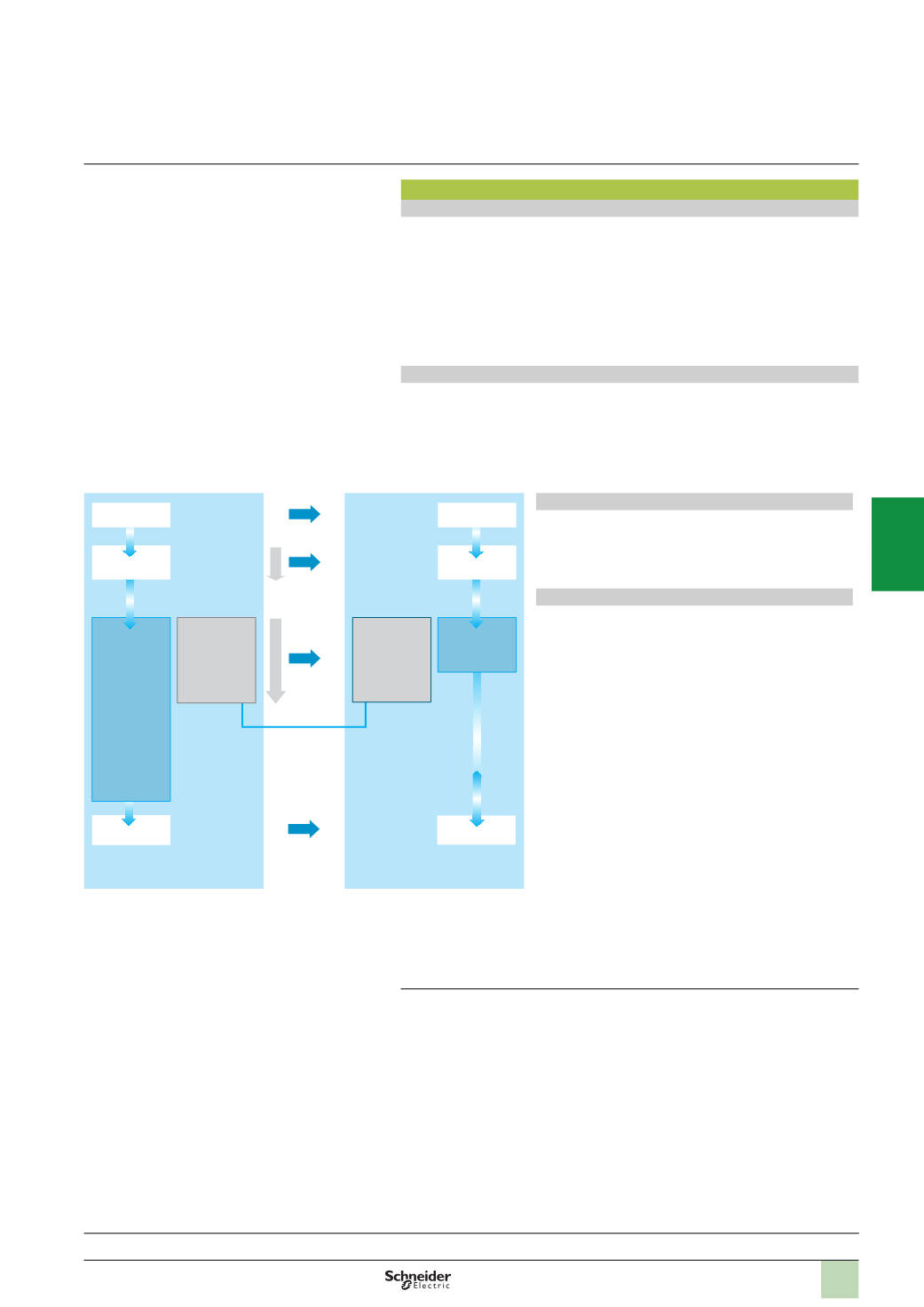

1

2

Inputs

Hot Standby

Application

program

Inputs

Hot Standby

Application

program

(1

st

section only)

Outputs

Data

(

coprocessor)

Data

(

coprocessor)

CPU Sync link

Primary PLC

Standby PLC

Outputs

Configuration

The installation of the application program does not differ

fundamentally from installing a program for a single PLC.

It essentially uses the information requested by dedicated

dialogue boxes, filled in during configuration in Unity Pro.

Cyclic transfer of the application context

At the start of each scan cycle, the content of the Primary

PLC data memory is transferred to the Standby PLC via

the dedicated CPU Sync link, at the same time as the

contents of the I/O status tables are transferred to it. The

Hot Standby system is thus able to transfer, from the

Primary PLC to the Standby PLC, a data area (I/O image,

located internal data

(1)

and unlocated internal data) of:

v

192

KB max. with the

TSX H57 24M

processor

v

440

KB max. with the

TSX H57 44M

processor

The principle of the exchanges, as well as exchange times

according to the volume of data, are described in the

diagram opposite with:

1

Hot Standby system: 10 ms per 100 KB

2

Data transfer by the coprocessor: 30 ms per 100 KB.

This data transfer runs in parallel with execution of the

Primary PLC application program

Functions

(

continued)

Presentation:

page 4/52

Description:

page 4/53

Architectures:

pages 4/54 ...

References:

pages 4/60 ...

(1)

The first 100 %MW words in each located data area are not exchanged. They can therefore

be assigned to data for processing specific to each Primary or Standby PLC.

Modicon Premium automation

platform

Hot Standby system

Unity Pro software

2

1

3

4

5

6

7

8

9

10