PRODUCTS BY APPLICATION

Tel

+44 (0)1424 856600

Fax

+44 (0)1424 856611

Technical Hotline

+44 (0)1424 856688

26 |

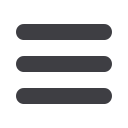

Case Study 2

Marshall-Tufflex GRP system for

Shoreham Harbour gantries

Marshall-Tufflex’s corrosion resistant Glass Reinforced

Polyester (GRP) cable management trays, which are

designed to withstand extreme weather conditions, have

been used to carry all power and lighting services to an

unloading station at Shoreham Harbour in West Sussex.

Built on the wharf, the station provides harbour side

docking and storage facilities for large quantities of steel

as it arrives aboard incoming ships.

With four 9m high x 120m long gantries plus cranes to

power and suspended gantries to light, the mechanical

and electrical services contractor needed cable trays for

the entire length of the gantries that would not corrode in

the harsh coastal location.

Approximately 500 linear metres of Marshall-Tufflex’s GRP

cable management trays, which are corrosion resistant

and equal in strength but up to 40% lighter than steel,

were specified. They are easier to handle than steel and

can help to reduce the overall weight of heavy structures.

To simplify installation, Marshall-Tufflex GRP products

require fewer fasteners and benefit from interlocking and

self-adjusting couplings for fast, on-site assembly without

modification, earth bonding or de-burring.

Marshall-Tufflex GRP systems are developed for

challenging environments such as rail, road and sea

installations, petrochemical and processing plants, where

extremes of weather and temperatures are commonplace.

They are manufactured from long lasting, low smoke

classified, zero halogen, glass reinforced polyester resin,

which remains effective in temperatures ranging from –

80°C to + 130°C. They also have a slow rate of heat transfer

with low conductivity and self-extinguishing properties

and are resistant to electromagnetic pulses.

Cable management for transport and industrial environments

Case Study 3

Marshall-Tufflex systems ensure no delays at

600million Dublin Airport passenger terminal

Behind the scenes at Terminal 2, the flagship project

of the €2 billion redevelopment of Dublin Airport,

are thousands of metres of Marshall-Tufflex trunking

products, selected for their ease and speed of

installation, good looks and short lead times.

Substantial amounts of three-layer LSOH MT Supertube

conduit are installed at high level and within ceilings

in the main Terminal building, satisfying the project

consultant’s requirement for mechanical protection/

segregation and a good architectural aesthetic.

Client Dublin Airport Authority had originally specified steel

conduit but the project’s engineering contractor, Mercury

Engineering, gained agreement for a specification change

to MT Supertube. A spokesman said: “It was a really tight

construction programme which I knew would benefit

from the time-saving features of certain Marshall-Tufflex

products. MT Supertube offered two specific advantages

over steel conduit. Not only is it much quicker to install,

delivering significant labour saving benefits, it is also much

lighter. This meant that when installed at height it was a

one man, rather than a two man, lift.”

Thousands of metres of Marshall-Tufflex’s unique, all-

curved profile trunking Odyssey were also installed in

some 150 offices within Terminal 2. The good-looking

Cat 6 compliant profile was also installed in passenger

booking kiosks, immigration booths, car rental offices and

other front-of-house desk areas.

All Marshall-Tufflex products were supplied by its sole

Irish distributor, Core Electrical Ltd.