PRODUCTS BY APPLICATION

Case Study 1

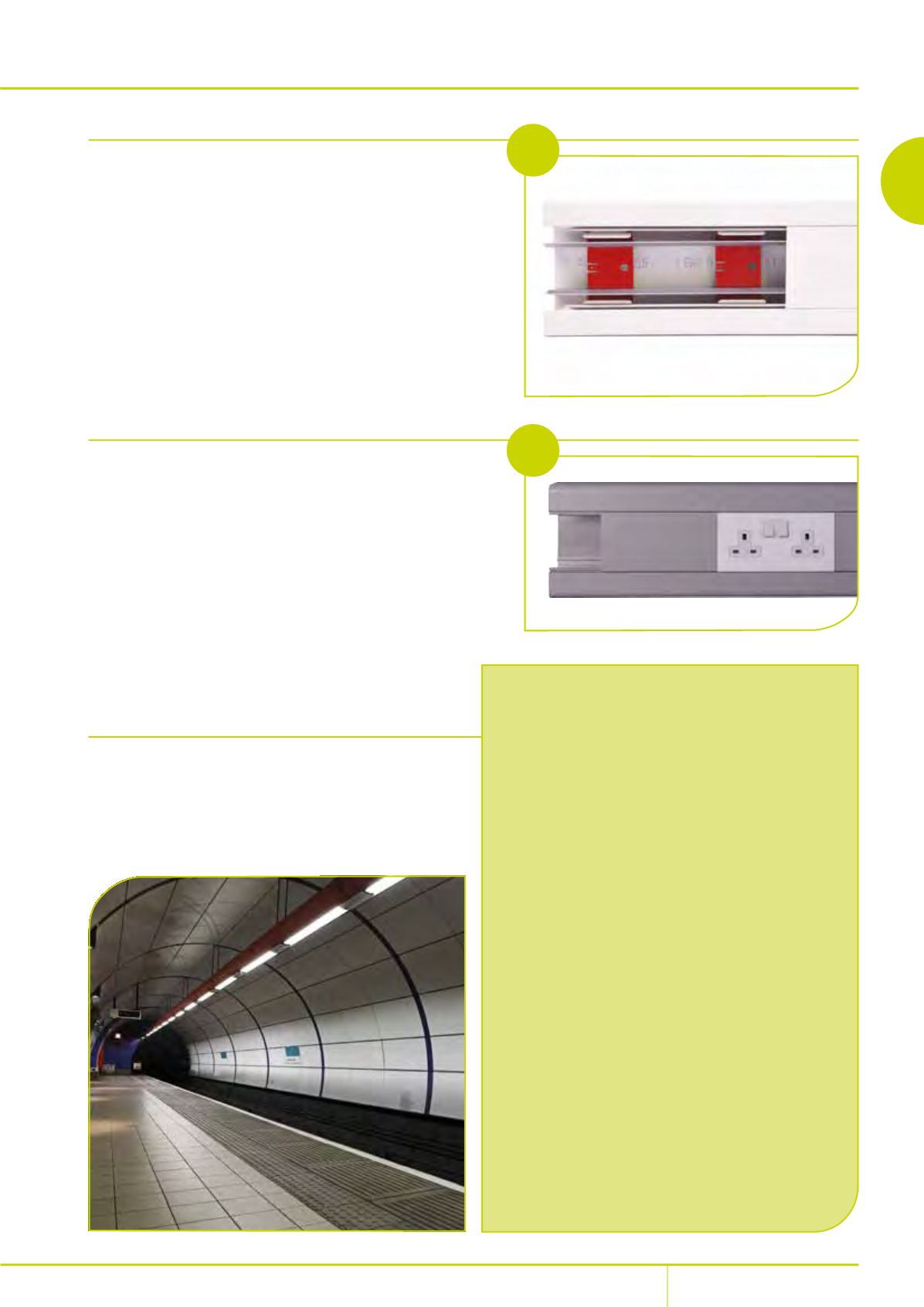

Marshall-Tufflex keeps London Underground

in the picture

| 25

Marshall-Tufflex’s MT Supertube FR, formulated for

applications where fire safety regulations are at their

most stringent, was a key component in the upgrade of

London Underground’s Victoria Line OPO CCTV camera

system, with more than five miles (8,100m) of the high-

performance conduit installed.

Manufactured from a special three-layer LSOH conduit,

MT Supertube FR delivered a superior design solution

to protect cables that transmit images of the platforms

to the train driver. MT Supertube FR is an alternative

to steel trunking, offering much faster fit times. It is

supplied in coils of up to 100m and therefore produces

little wastage from cut lengths.

For the London Underground project MT Supertube

FR’s EMC shielding capabilities were of paramount

importance, as the specifying contractor explained:

“We chose MT Supertube for its ability to provide EMC

shielding. It has proved a better way to segregate cables,

which is greatly beneficial in London Underground

applications where there are a lot of unknown cables to

contend with.”

MT Supertube FR meets London Underground’s fire and

materials specification, having undergone a series of

tests conducted against the rigorous requirements set

out by London Underground Ltd.

A Marshall-Tufflex spokesman said: “Having product

specified for use in the London Underground system is

of immense importance to us and a big rubber stamp

for MT Supertube FR. The Underground is a demanding

environment that calls for products of the highest calibre

and performance.”

Steel has a mechanical strength that makes it a robust and durable option

for public areas where there is a high footfall. Our steel trunking provides

Specifiers, Contractors and end-users with reliable, practical systems with

hard-wearing, clean lines and all the advantages of inherent LSOH and

screening properties.

The extra depth provided by Marshall-Tufflex steel perimeter trunking

systems offer increased capacity for power and data services. All earth

bondings are ‘friction fit’ to eliminate the need for unsightly screw fixings.

•

Easy to install steel trunking system

•

Well known, proven and stylish design

•

Increased space internally

•

Lighter weight to make installation easier

•

Simpler to cut

Aluminium perimeter trunking systems provide the Specifier, Contractor

and end-user with elegant, stream-lined containment that offers the

practical advantages of inherent LSOH and screening properties making

it ideal for industrial environments.

Aluminium is light to handle with a mechanical strength and impact-

resistance that is superior to steel. Extruded sections provide attractive

profiles and products are finished with a high quality, powder-coat that

provides a blemish-resistant surface.

Steel trunking systems

Aluminium trunking systems

Page

183

Page

157

Cable management for transport and industrial environments