123

Reliability and durability

The two major considerations for the network infrastructures are

the reliability and durability of the installation. In order to measure

the positive contribution made by Cablofil steel wire cable tray,

even when overloaded with cables, a series of independent tests

were carried out.

• Independent tests

The aim was to develop a detailed understanding of the short-

term or long-term benefits of using Cablofil steel wire cable

tray, as opposed to conventional flat-bottomed supports, for Cat.

5e and Cat. 6 cables. Cablofil steel wire cable tray lengths were

tested by Intertek Testing Services, a division of ETL, the world’s

leading provider of testing, inspection and certification services.

• Measurements

For the two tests described below, parameters relating to cable

characteristics (NEXT, FEXT, Attenuation Return Loss, etc.)

are measured in different configurations. The main parameter

selected for comparison purposes is Return Loss. The aim is to

define a cable’s impedance regularity. Each irregularity causes

the signal to return to its source.

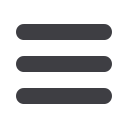

• Test 1 : reliability under load

90 metres of Cat. 5e and Cat. 6 cables were tested with no load,

before being subjected to mechanical stress equivalent to the

weight of 40 cables stacked together. Measuring and comparing

the Return Loss for each configuration determines the effect of

the support.

Results :

The tests show that, for a Category 5e or Category 6 cable

subjected to a load of 40 cables, there is no significant difference

in behaviour between Cablofil steel wire cable tray and a support

with a flat base.

Cablofil steel wire cable

tray not loaded

Cablofil steel wire cable

tray under load

Flat surface not loaded

Flat surface under load

Test configuration

<

1

m

Ω

• Test 2 : durability under load

In order to establish how data cable installations change over

time, the equipment is subjected to a simulated 15 year ageing

process based on extremely stringent military standards and the

same tests are performed. The cables and supports undergo 200

cycles over large temperature variations (-40°C to +85°C) over a

period of 2 weeks.

Results :

The cable supported by Cablofil steel wire cable tray, an open

and ventilated system, performs better than a cable laid directly

on the floor.

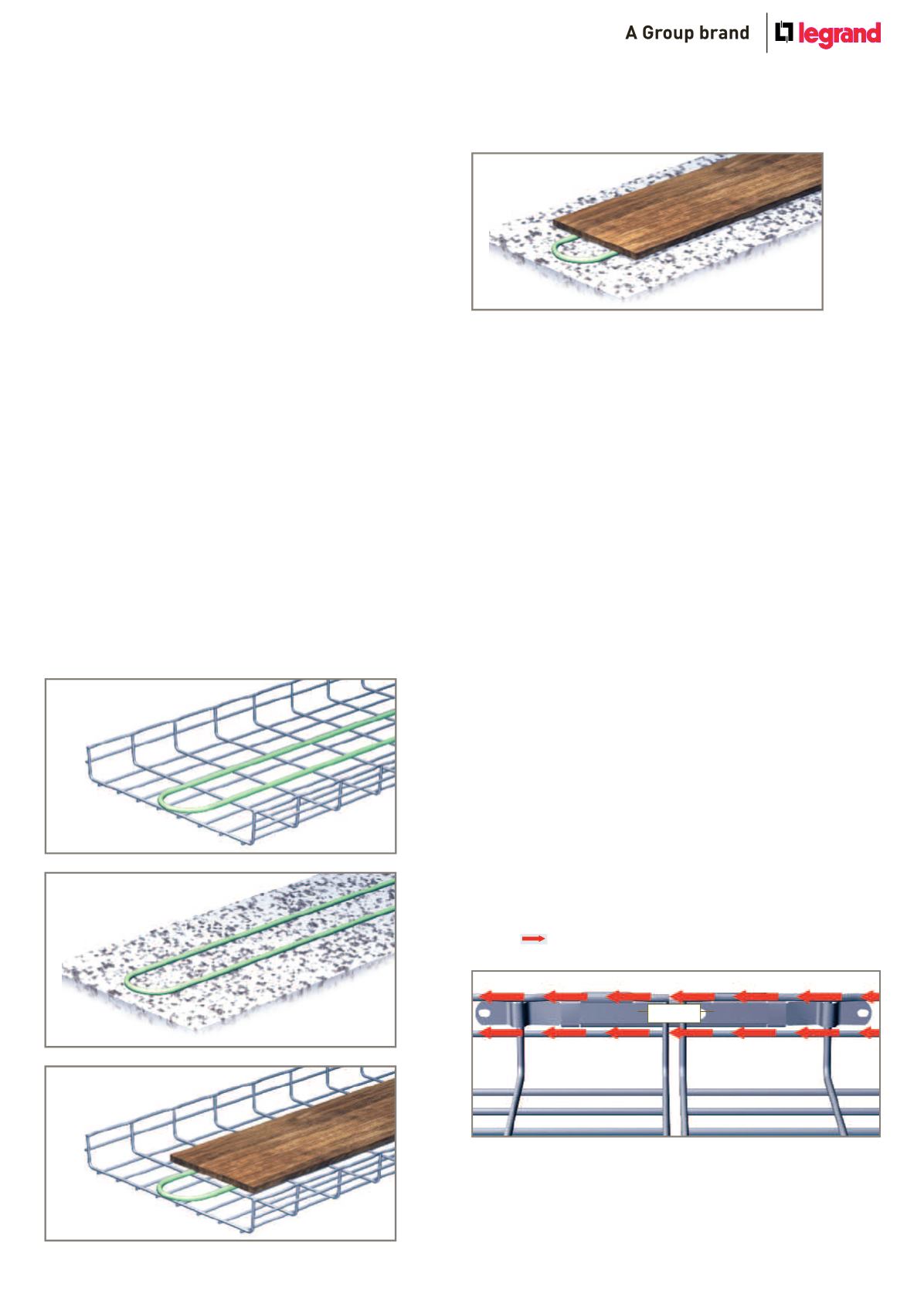

(ix) Electrical continuity

Fundamental to providing safety to people and property,

electrical continuity also plays an essential role in the EMC

performance of an electrical installation.

Definition

The electrical continuity of a system is its ability to conduct

electric current. Each system is characterised by its

resistance (R).

If R = 0

Ω

, the system is a perfect conductor.

If R is infinite, the system is a perfect insulator.

The lower the system’s resistance, the better its electrical

continuity will be.

The importance of excellent electrical continuity

Even at the same electrical potential each part of the steel wire

cable tray run helps dissipate any fault currents :

Tested for electrical continuity

•

Steel wire cable tray lengths

Tests show that Cablofil steel wire cable tray lengths more

than meet the requirements of the standard IEC 61537, which

stipulates that cable tray resistance must not exceed 5 m

Ω

/m.

•

Steel wire cable tray couplers

The standard IEC 61537 states that coupler resistance must not

exceed 50 m

Ω

. The test involves running an electric

current through the system (lengths + couplers) and

measuring coupler resistance.

Test results

An average of 0·82 m

Ω

for Cablofil couplers. This is between 50

and 80 times better than the requirements given in the standard.

All Cablofil couplers are tested and compliant.

Please contact our technical support team on +44 (0)845 605

5334 for the full results of these tests.