122

®

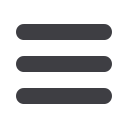

(viii) Testing of cables within a support system

Short circuits

When an electrical short circuit occurs under fault conditions the

current that flows can, in some instances, reach tens of thousands

of amps and can last from a few milliseconds to several seconds

depending on the electrical installation requirements. Such short

circuit currents produce high magnetic fields which can interact

to produce large mechanical forces. These forces can cause

significant displacement of the cables and therefore some form of

restraint must be provided to prevent damage to the cables.

For large diameter cables the most common form of restraint is

by the use of cable cleats which hold the cables to the steel wire

cable tray. Some force may therefore be transferred to the steel

wire cable tray via the cable cleat, and could be sufficient to cause

damage to the steel wire cable tray.

The calculation of the forces is complex and the effect on a steel

wire cable tray system can only be fully determined by testing.

The main causes of short circuits are as follows :

• Damage to insulating material as a result of wear and tear or

mechanical impact

• Broken conductors

• Conducting elements falling onto or otherwise coming into

contact with the circuit

Short circuit tests

Tests were performed at a recognised independent laboratory

(DAMSTRA) and in accordance to standard EN 50368 (2003)

- Cable cleats for electrical installations, in order to validate

Cablofil steel wire cable tray’s mechanical resistance to the stress

generated by a short circuit.

An initial short circuit is generated during the tests, creating

mutual electromagnetic repulsion between the power cables.

The cable tray is then subjected to substantial mechanical stress

for a very short time (approx. one second).The process is repeated

in order to demonstrate that Cablofil steel wire cable tray is

structurally intact and able to cope with another short circuit.

As a final measure, additional tests are performed in a damp

environment to check whether the cables are fully intact.

The various tests are run with 3 successive levels of short circuit

current :

• 70 kA, equivalent to a repulsive force of 1300 daN

• 100 kA, equivalent to a repulsive force of 2700 daN

• 130 kA, equivalent to a repulsive force of 4500 daN

Material used : 3 m length of CF105/450, coupled 1/5 of the way

along the span, 5 fast couplers and a support span of 1·5 metres.

System configuration : 3 single conductor power cables, 38 mm in

diameter, are attached every 600 mm using cleats.

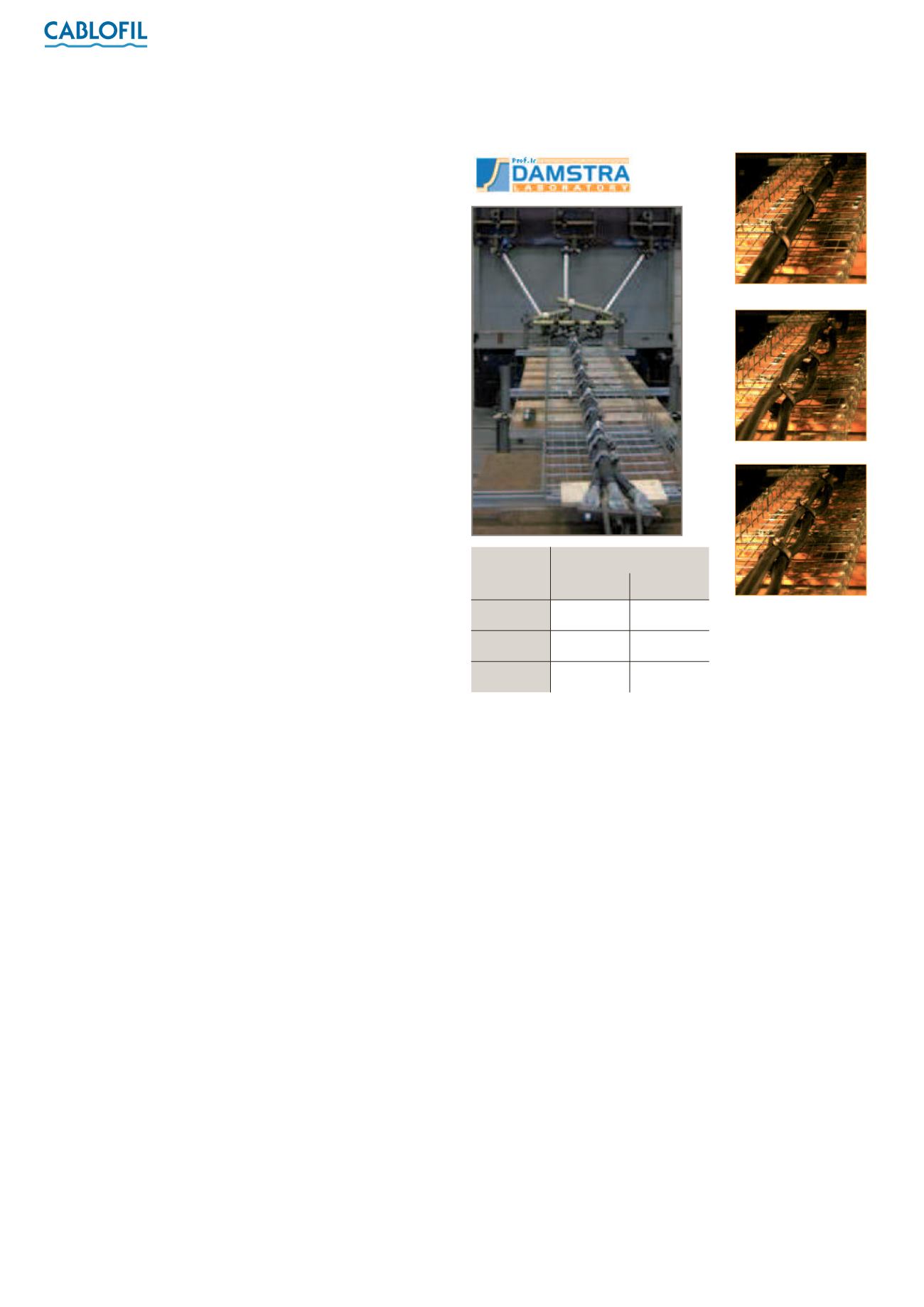

Conclusion

The tests reveal that the steel wire cable tray shows no permanent

deformation - its mesh structure is able to absorb the physical

stress generated by a significant short circuit current.

The cables remain intact in their original positions and network

availability is maintained.

After test

During test

Before test

Class

Intensity

Class 1

Class 2

70 kA

100 kA

130 kA