113

n

3L + N + PE copper

Rated current

I

n

[A]

800

1000

1250

1600

2000

2500

3200

4000

5000

Casing overall dimensions

L x H [mm] 130x130 130x130 130x130 130x170 130x170 130x220 130x380 130x440 130x480

Operating voltage

U

e

[V]

1000

1000

1000

1000

1000

1000

1000

1000

1000

Insulation voltage

U

i

[V]

1000

1000

1000

1000

1000

1000

1000

1000

1000

Frequency

f [Hz]

50/60

50/60

50/60

50/60

50/60

50/60

50/60

50/60

50/60

Rated short-time current for three-phase fault (1 s) I

cw

[kA]rms

45

50

60

85

88

88

170

176

176

Allowable peak current for three-phase fault

I

pk

[kA]

95

110

132

187

194

194

374

387

387

Rated short-time current for single-phase fault (1 s) I

cw

[kA]rms

27

30

36

51

53

53

102

106

106

Allowable peak current for single-phase fault

[kA]

57

66

79

112

116

116

224

232

232

Allowable specific energy for three-phase fault

I

2

t [MA

2

s]

2025

2500

3600

7225

7744

7744

28900

30976

30976

Phase resistance

R

20

[m

Ω

/m] 0·041

0·032

0·032

0·024

0·020

0·016

0·012

0·010

0·008

Phase reactance (50 Hz)

X [m

Ω

/m]

0·023

0·017

0·017

0·015

0·014

0·011

0·007

0·006

0·006

Phase impedance

Z [m

Ω

/m]

0·047

0·037

0·037

0·028

0·024

0·019

0·014

0·012

0·010

Phase resistance at thermal conditions

R

t

[m

Ω

/m] 0·045

0·037

0·040

0·029

0·024

0·019

0·015

0·013

0·010

Neutral resistance

R

20

[m

Ω

/m] 0·023

0·017

0·017

0·015

0·014

0·011

0·007

0·006

0·006

Phase impedance at thermal conditions

Z [m

Ω

/m]

0·050

0·041

0·043

0·033

0·028

0·022

0·016

0·014

0·012

Resistance of the protective conductor (PE 1)

R

PE

[m

Ω

/m] 0·125

0·125

0·125

0·113

0·113

0·101

0·075

0·069

0·065

Resistance of the protective conductor (PE 2)

R

PE

[m

Ω

/m] 0·036

0·036

0·036

0·028

0·028

0·023

0·014

0·012

0·011

Resistance of the protective conductor (PE 3)

R

PE

[m

Ω

/m] 0·050

0·050

0·050

0·041

0·041

0·033

0·021

0·018

0·017

Reactance of the protective conductor (50 Hz)

X

PE

[m

Ω

/m] 0·054

0·054

0·054

0·044

0·044

0·032

0·022

0·017

0·016

Resistance of the fault loop (PE 1)

R

o

[m

Ω

/m] 0·170

0·162

0·165

0·142

0·137

0·120

0·090

0·082

0·075

Resistance of the fault loop (PE 2)

R

o

[m

Ω

/m] 0·081

0·073

0·076

0·057

0·052

0·042

0·029

0·025

0·021

Resistance of the fault loop (PE 3)

R

o

[m

Ω

/m] 0·095

0·087

0·090

0·070

0·065

0·052

0·036

0·031

0·027

Reactance of the fault loop (50 Hz)

X

o

[m

Ω

/m] 0·077

0·071

0·071

0·059

0·058

0·043

0·029

0·023

0·022

Impedance of the fault loop (PE 1)

Z

o

[m

Ω

/m] 0·186

0·177

0·179

0·154

0·149

0·128

0·094

0·085

0·078

Impedance of the fault loop (PE 2)

Z

o

[m

Ω

/m] 0·111

0·102

0·104

0·082

0·078

0·060

0·041

0·034

0·030

Impedance of the fault loop (PE 3)

Z

o

[m

Ω

/m] 0·122

0·112

0·114

0·092

0·087

0·068

0·046

0·039

0·035

Zero-sequence resistance phase - N

R

o

[m

Ω

/m] 0·170

0·155

0·155

0·115

0·120

0·098

0·083

0·071

0·062

Zero-sequence reactance phase - N

X

o

[m

Ω

/m] 0·159

0·151

0·151

0·114

0·098

0·065

0·056

0·055

0·042

Zero-sequence Impedance phase - N

Z

o

[m

Ω

/m] 0·233

0·216

0·216

0·162

0·155

0·118

0·100

0·090

0·075

Zero-sequence resistance phase - PE

R

o

[m

Ω

/m] 0·507

0·429

0·429

0·331

0·283

0·221

0·177

0·178

0·144

Zero-sequence reactance phase - PE

X

o

[m

Ω

/m] 0·201

0·177

0·177

0·143

0·150

0·124

0·111

0·094

0·086

Zero-sequence Impedance phase - PE

Z

o

[m

Ω

/m] 0·545

0·464

0·464

0·361

0·320

0·253

0·209

0·201

0·168

cos

ϕ

= 0·70 41·3

33·0

34·6

27·1

23·5

18·5

13·2

11·5

9·8

cos

ϕ

= 0·75 42·1

33·8

35·5

27·7

23·9

18·8

13·5

11·8

9·9

cos

ϕ

= 0·80 42·8

34·5

36·3

28·1

24·2

19·1

13·8

12·1

10·0

cos

ϕ

= 0·85 43·3

35·0

37·0

28·4

24·4

19·2

14·0

12·2

10·1

cos

ϕ

= 0·90 43·4

35·3

37·3

28·5

24·4

19·2

14·1

12·3

10·1

cos

ϕ

= 0·95 42·9

35·1

37·2

28·2

23·9

18·8

14·0

12·2

9·8

cos

ϕ

= 1·00 38·6

32·1

34·4

25·4

21·2

16·7

12·7

11·2

8·7

Weight (PE 1)

p [kg/m]

28·9

32·6

32·6

41·8

47·9

60·6

79·0

93·4

116·7

Weight (PE 2)

p [kg/m]

38·4

42·1

42·1

54·2

60·3

76·8

103·4

122·3

148·6

Weight (PE 3)

p [kg/m]

32·0

35·7

35·7

45·8

51·9

65·9

87·0

102·8

127·1

Fire load

[kWh/m]

4·5

5·5

5·5

8

8·2

10·5

16

19

21

Degree of protection

IP

55

55

55

55

55

55

55

55

55

Thermal resistance class of the insulating materials

–

B/F

1

B/F

1

B/F

1

B/F

1

B/F

1

B/F

1

B/F

1

B/F

1

B/F

1

Joule effect losses at rated current

P [W/m]

86

111

186

225

294

361

451

619

750

Min./max. ambient temperature

[°C]

-5/50

-5/50

-5/50

-5/50

-5/50

-5/50

-5/50

-5/50

-5/50

Voltage drop factor with

distributed load

k [V/m/A]10

-6

∆

V = k.L.Ie.10

-6

[V]

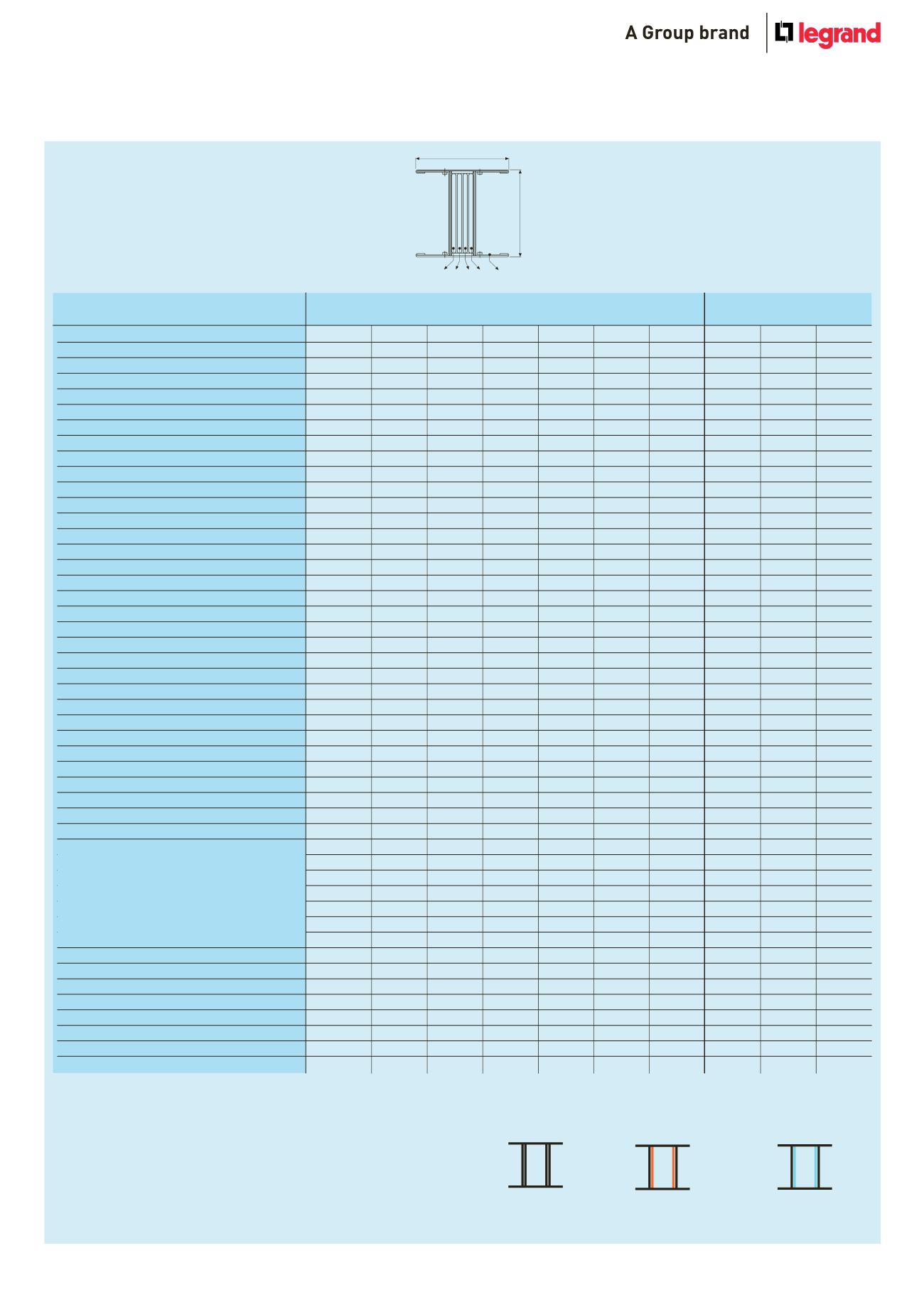

Single bar

Copper

Double bar

Regulations and conformity :

IEC/EN 60439-1 and 2; DIN VDE 0660 500 and 502

Product suitable for Constant/Cyclic Warm, humid climates :

DIN IEC 68 part 2-3; DIN IEC 68 part 2-30

Degree of protection :

IP 55; IP x7 carrying lines available with accessories, on request - +44 (0) 845 600 6266

Insulation and surface treatment of the conductors :

Insulated conductors for the whole length, aluminum copper-plated and tin-plated

Busbar casing material :

1·5 mm galvanised steel plate, pre-painted or stainless steel

(available, if required, with special paint and/or with thickness 2 mm)

1 : Class F thermal resistance (155°C) available on request

-

+44 (0) 845 600 6266

In : rated current referred to a room temperature of 40°C

PE 1

Standard version

PE 2

Extra earth - copper

PE 3

Extra earth - aluminium

N

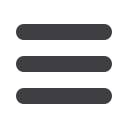

PE L3 L2 L1

130

H

SCP super compact busbar

– 4 conductor (copper)

technical data