111

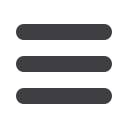

Fig. 1

Fig. 2

Fig. 3

270 mm

Fig. 5

Fig. 6

Fig. 4

85Nm

n

Installation sequence of the junction

Installation instructions are included near the junction (Fig.1)

Make sure that the contacts are clean before joining lengths

Install the junction covers (Fig. 5)

Completed IP 55 installation (Fig. 6)

For further information, please contact us on +44 (0) 845 600 6266

Tighten the bolt of the monobloc until the 1st head breaks off

(Fig. 4)

The bolt that tightens the monobloc has a second head which is

used when carrying out operations or inspections on the line

The nominal tightening torque is 85Nm

Make sure that the earth plate of the trunking length is inserted

behind the front plate of the junction monobloc (Fig.2)

The positioning pin on the monobloc should be fitted into the

corresponding slot on the earth plate. Verify the distance between

lengths, 270 mm, before tightening the monobloc completely (Fig.3)

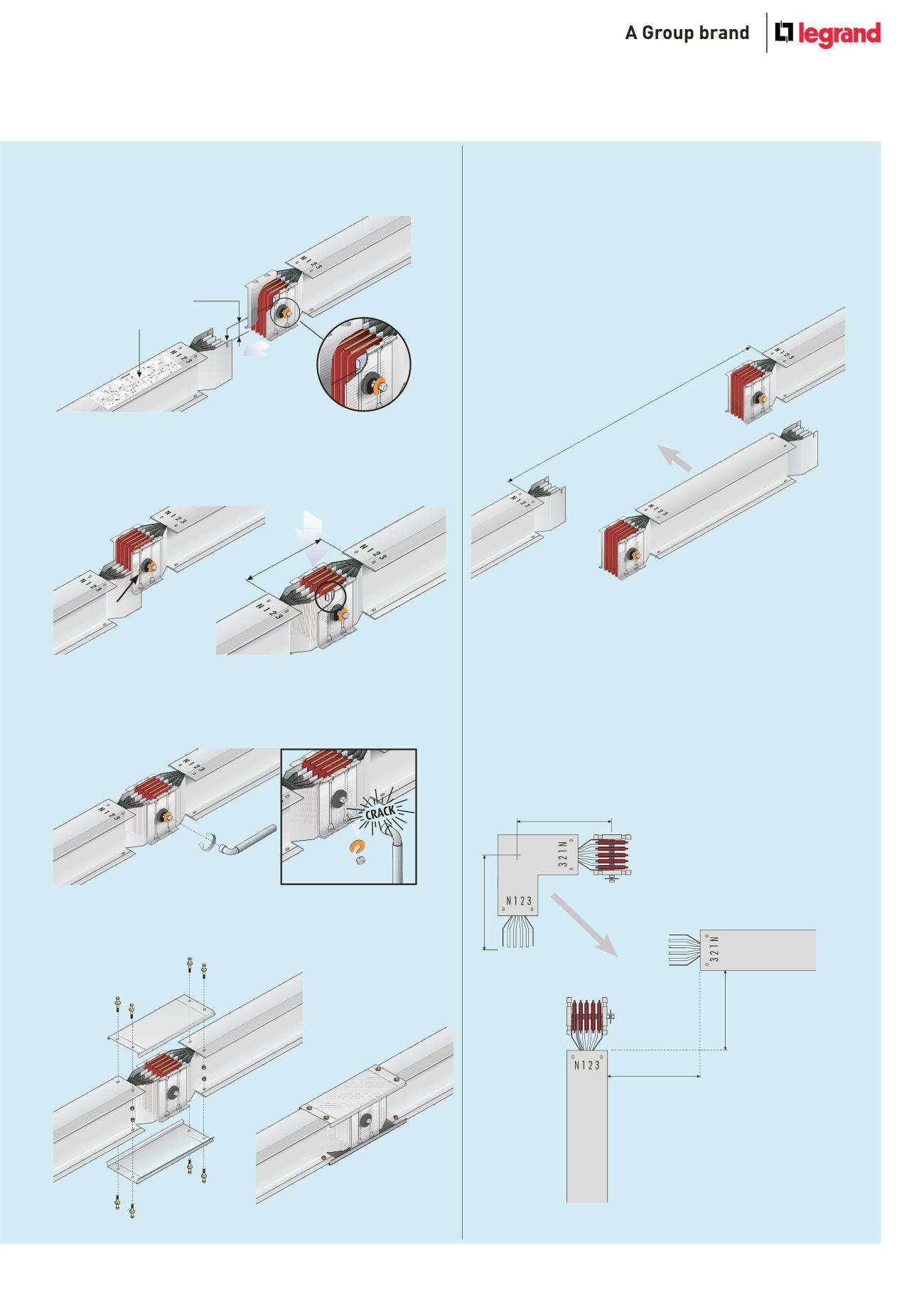

30 mm

Measurement of trunking lengths

The exact length to be ordered can be determined by measuring

the distance between the components (as shown below) and then

subtracting 270 mm

Length = Q - 270 mm

Example : dimension measured = 2500 mm

length required = 2 230 mm

n

Measurement of bespoke components

N1 2 3

N1 2 3

N1 2 3

dimension Q

Q2

Q1

B = Q2 - 70 mm

A = Q1 - 70 mm

Horizontal elbow

The exact length to be ordered can be determined by measuring the

dimensions Q1 and Q2 (as shown below) and then subtracting 70 mm

from each dimension

A = Q1 - 70 mm

B = Q2 - 70 mm

For further information, please contact us on +44 (0) 845 600 6266

Instructions

All dimensions (mm) are nominal

1

2

3

4