SCP

super compact busbar

technical information

106

All dimensions (mm) are nominal

Aluminium

Copper

Rating (A)

(m)

Rating (A)

(m)

630

17

–

–

800

16

800

10

1000

16

1 000

9

1250

15

1 250

9

1600

12

1 600

7

2000

10

2 000

6

2500

14

2 500

4

3200

12

3 200

7

4000

10

4 000

6

–

–

5000

5

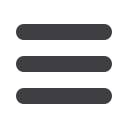

Horizontal installation fixing

Fixing recommended : 1 bracket every 1·5 m

n

Fixing in standard conditions

For vertical path sections of less than 2 m the use of standard

suspension brackets is sufficient

Edgeways length

Flat length

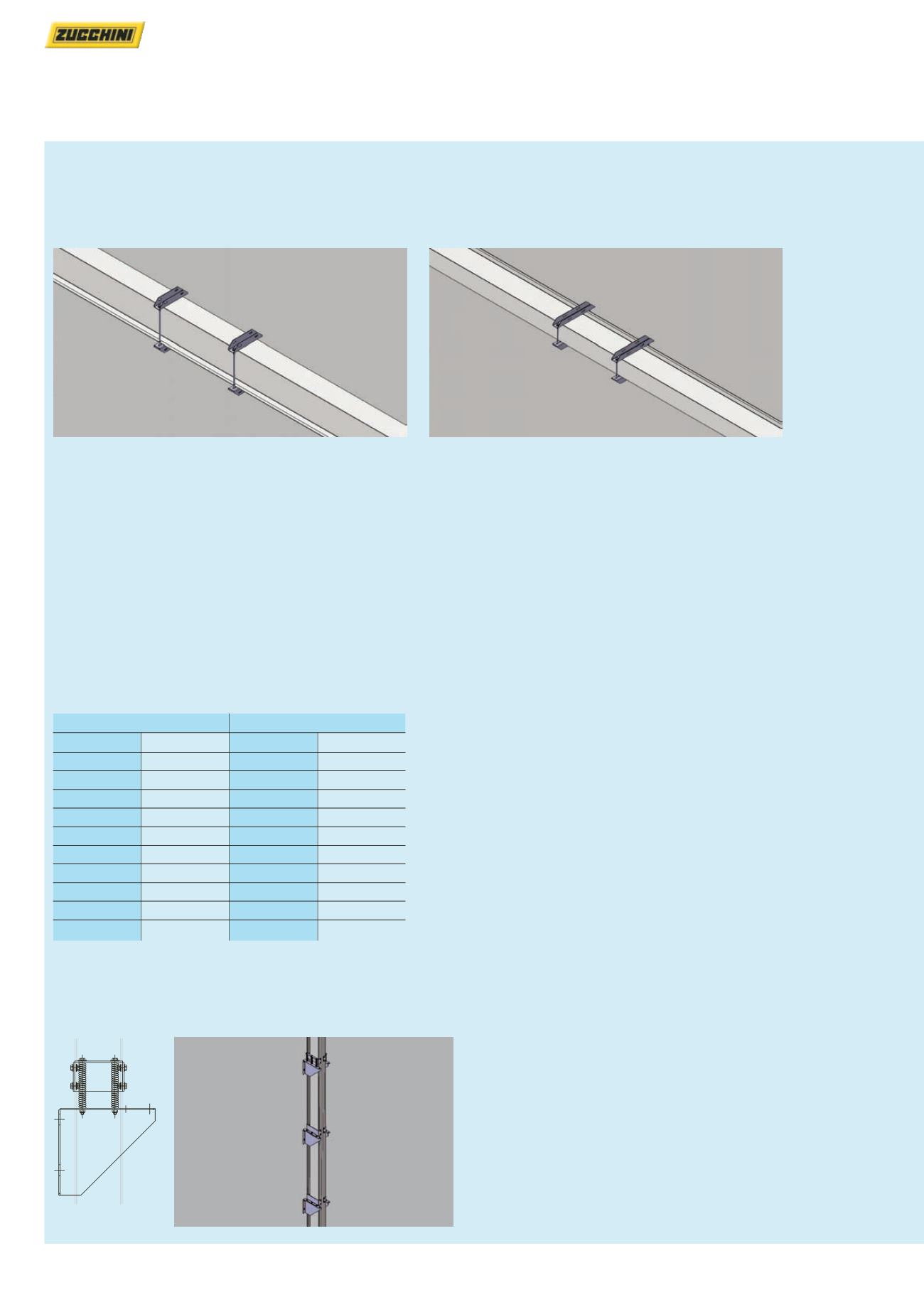

Vertical installation fixing (rising mains)

In the case of rising mains, in addition to the standard brackets, it will

also be necessary to use other screw fixed brackets to prevent the

busbar sliding

Due to their pre-loaded springs, the brackets absorb the forces

pressing on the busbar and direct any expansion in a precise direction

They therefore operate as a limitation, and support the traction and

compression forces of the busbar trunking system

• Section between 2 and 4 m

In the lowest point Type B vertical bracket if secured to the wall, or

Type D if secured to the floor and one edgeways installation bracket

• Section of over 4 m

In the lowest point Type A vertical bracket if secured to the wall, or

Type C if secured to the floor and one edgeways installation bracket

every 1·5 m of the path and one Type A or C bracket based on the

following table

Edgeways length

n

Fixing for installation in seismic environments

Vertical installation (section lengths > 2 m)

Fit 1 bracket every 1·5 m of the busbar

Every 2 anti-seismic brackets with bracket (Type B) use one bracket

with bracket and spring (Type A)