13/4

Safety relays

2010

CA08103002Z-EN

www.eaton.comSafety

Safety

Description

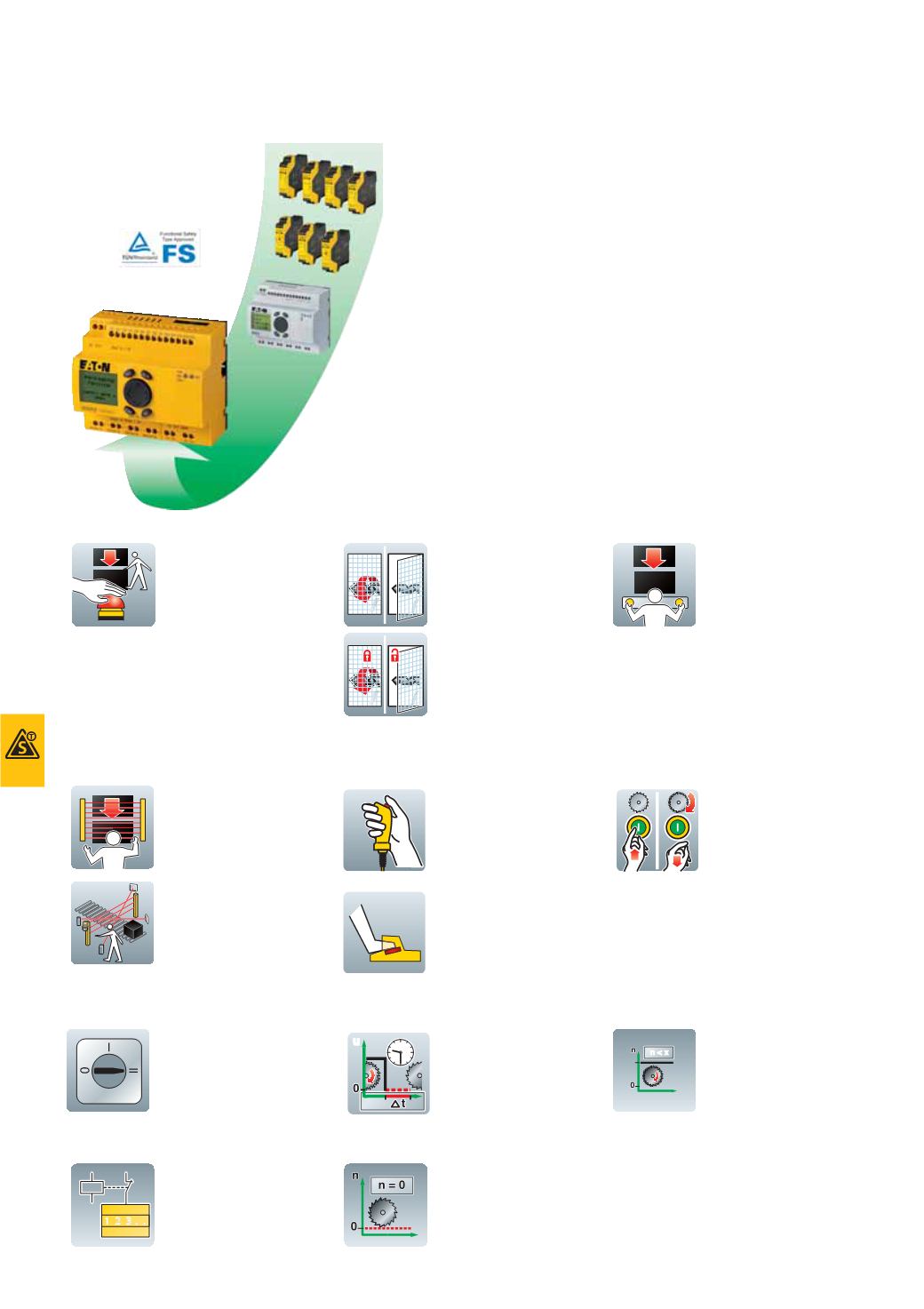

The easySafety control relay for safety-related applications monitors all commonly

used safety devices and also takes over the required control tasks for the machine.

Packed with a host of conventional safety relays in the form of safety function blocks,

easySafety not only features integrated safety functions but also standard functions

in a single device – all in one.

In addition to the safety circuit diagram containing the safety configuration, the safety

control relay also contains a standard circuit diagram. This circuit diagram can be

used for standard tasks, such as the processing of diagnostics signals or general

control tasks of a machine.

Thanks to the large number of safety function blocks, this provides the user with a

number of application options with only one device. The user can now also respond

directly to future and changing application requirements. This saves financial

resources and offers future investment security. Last but not least, it reduces the

stock-keeping required for special safety relays.

easySafety meets the requirements of category 4 to EN 954‐1, PL e to EN ISO 13849‐1,

SILCL 3 to EN IEC 62061 and SIL 3 to EN IEC 61508. With easySafety, it is therefore

possible to implement applications meeting the most stringent safety requirements.

In addition to many standard function blocks from the easy800, easySafety offers the following safety function blocks:

Emergency stop circuits

Allows the safe stopping of a

hazardous movement,

immediate stop for Stop

category 0 and controlled

stop for Stop category 1

according to IEC 60204-1; for

use in single or dual channel

safety monitoring of emer-

gency stop circuits.

Guard door monitoring with

andwithout interlock/guard

locking

Used with moving guards

such as doors, barriers or

flaps. Positions are reliably

detected, monitored and

enabled to safety-related

requirements – optional

interlock device with guard

locking when increased

personal and process

protection are required; this

securely keeps the guard

closed until machine

standstill.

Safe operationwith two-hand

control

Type III to EN 574. Used for

hazardous machine move-

ment such as presses,

punching, shearing. It allows

the movement of hazardous

operation only when both

hands of the operator are out-

side the hazardous area and

the two pushbuttons are

operated within 0.5 seconds of

each other.

Electro-sensitive protective

devices (ESPE)

Protection of the hazardous

location or area in the vicinity

of machines by means of

contactless guards such as

light grids/light barriers/light

curtains.

Optionally with muting

function,

which temporarily bypasses

the protective function of a

safety device, such as a light

curtain. Typical applications

include feedingmaterials into

a machine without having to

interrupt the machine's

operation.

Enabling switch

The manual or foot operated

enable switch allows the

temporary enabling of a

guard, such as a safety door,

by continuous actuation.

This may be necessary for

setting or servicing a

machine.

Start device

For the safe starting of an

application by means of an

external start pushbutton or

start condition from the safety

circuit diagram.

Operating mode selector

switches

Used for the safe selection

and acceptance of a prese-

lected operating mode on an

external control circuit

device.

Safety timing relay

Used for changing the

switch duration and the on

or off switch points of an

enable contact in the safety

circuit. Safety-related timing

relay with on and/or off

delayed or single pulse

function.

Overspeed monitoring

For the safety-related

overspeed monitoring of a

motor or a shaft. If the

maximum speed is exceeded,

the drive is disabled.

Feedback loop monitoring

(

EDM)

Used for the safety-related

monitoring of externally

connected actuators, e.g.

contactors, relays or valves.

Zero monitoring

Used when the entry or

access to the hazardous

area is not permitted until

the hazardous driving force

has come to a standstill.

u

n < x

. .

1 2 3