TECHNI CAL DATA

POWERSTAR

71

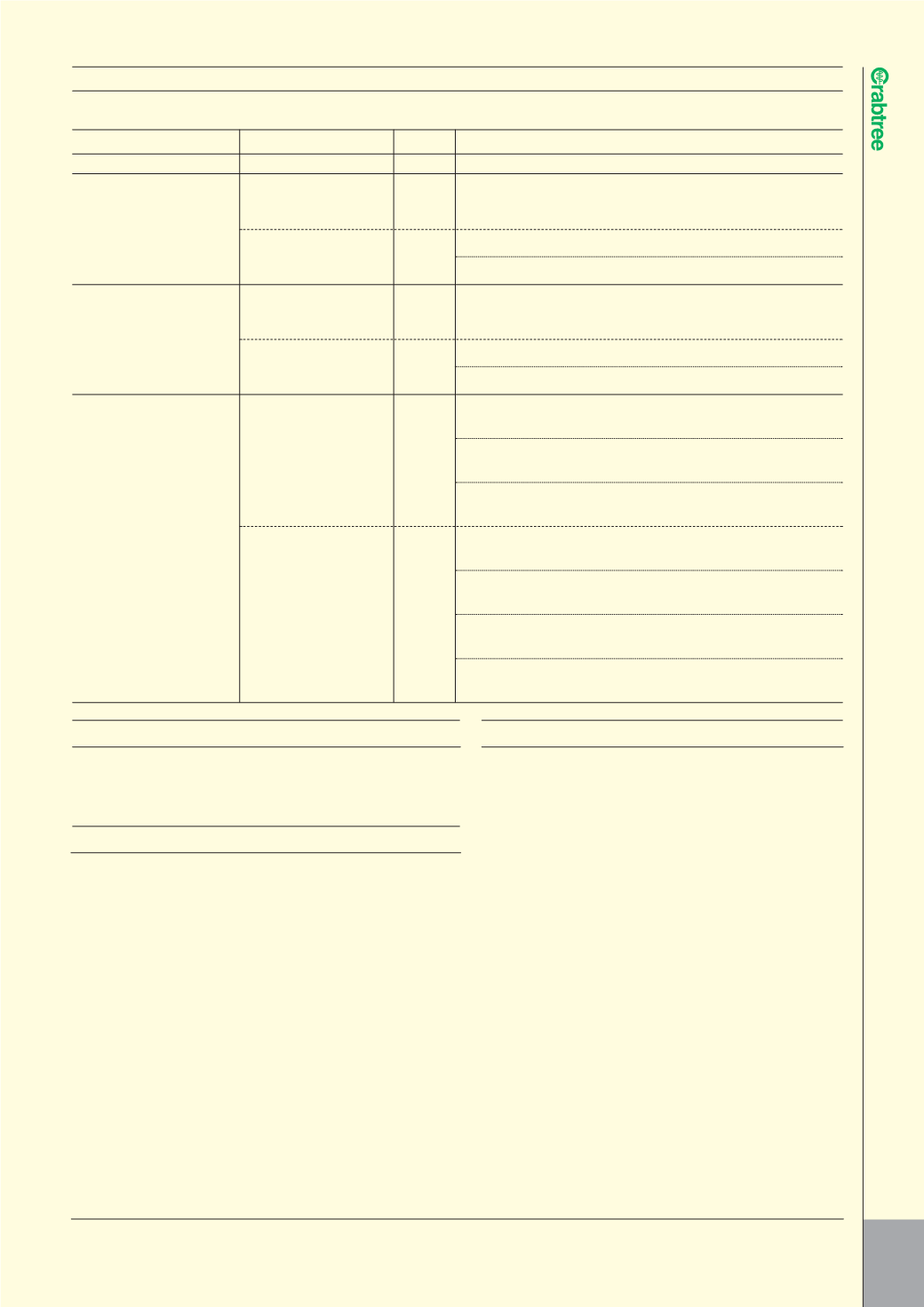

BSEN61439-1 : FORMS OF SEPARATION

l

FORMS OF SEPARATION

l

As described in BSEN60439-1 the Forms of Separation comprise four

levels as detailed in the above table. The various methods of achieving

separation can involve sleeving the busbars inside a separate box or a

combination of both methods.

COST EFFECTIVE SPECIFICATION

l

In order to gain maximum benefit from the standard it is necessary to

consider the application for which the switchboard is required and the

appropriate level of separation for the environment in which it is to be

installed. For example a Form 4 switchboard may be appropriate where

general access is permitted to the switch room but where the

switchboard is in a locked substation with access restricted to qualified

personnel, a lesser degree of separation may be more appropriate.

TYPICAL APPLICATIONS

l

Form 1 – No separation

Typical applications are places where the switchboard is in a secure

location and where failure of the switchboard will cause little or no

additional disruption to other areas being fed by the switchboard.

Form 2 – Separation of busbars from functional units.

Applications may well be the same as Form 1 but where it is

important that a fault in the switchboard need not affect all

functional units being fed from the same busbar system.

Form 3 – Separation of busbars from functional units and

the functional units from one another but not

their terminations.

Should be applied where it is important to provide protection from

internal live parts and where failure of functional units being fed

from the same busbar would cause unacceptable disruption.

Form 4 – Separation of busbars from functional units and

the functional units from one another including

their terminations.

Should be applied where it is important to provide protection from

internal live parts and where failure of functional units being fed

from the same busbar would cause unacceptable disruption.

Because all the terminations are separated it is possible to isolate

and work on a single functional unit.

- Separation of busbars from all

functional units

- Separation of all functional

units from one another

- Seperation of terminals for

external conductors associated

with a functional unit from the

terminals of any other

functionl unit and the busbars

- Seperation of the external

conductors from the busbars

- Seperation of the external

conductors associated with a

functional unit from other

functional units and their

terminals

- External conductors need not

be separated from each other

- Separation of busbars from all

functional units

- Separation of all functional

units from one another.

- Separation of terminals for

external conductors from the

functional units, but not from

the terminals of other

functional units.

Separation of busbars from all

functional units.

Terminals for external

conductors not separated

from busbars.

Terminals for external

conductors separated from

busbars.

Terminals for external

conductors in the same

compartment as the

associated functional unit.

Terminals for external

conductors not in the same

compartment as the

associated functional unit,

but in individual, separate,

enclosed protected spaces or

compartments.

Terminals for external

conductors not separated

from busbars.

Terminals for external

conductors and external

conductors separated from

busbars.

Form 2a

Form 2b

Form 3a

Form 3b

Form 4a

Form 4b

Type 7. All separation requirements are by metallic or non-metallic rigid barriers

or partitions. The termination for each functional unit has its own

integral glanding facility

Type 6. All separation requirements are by metallic or non-metallic rigid barriers

or partitions. Cables are glanded in common cabling chamber(s)

Type 5. Busbar separation is by metallic or non-metallic rigid barriers or

partitions. Terminals may be separated by insulated coverings and

glanded in common cabling chamber(s)

Type 4. Busbar separation is achieved by insulated covering, e.g. sleeving,

wrapping or coatings. Cables may be glanded elsewhere

Type 3. Busbar separation is by metallic or non-metallic rigid barriers or

partitions. The termination for each functional unit has its own integral

glanding facility

Type 2. Busbar separation is by metallic or non-metallic rigid barriers or

partitions. Cables may be glanded elsewhere

Type 1. Busbar separation is achieved by insulated covering, e.g. sleeving,

wrapping or coatings. Cables may be glanded elsewhere

Form

Form 1

Type of Construction

Sub criteria

Main criteria

No separation

FORMS OF SEPARATION

Type 1. Busbar separation is achieved by insulated covering, e.g. sleeving,

wrapping or coatings.

Type 2. Busbar separation is by metallic or non-metallic rigid barriers or

partitions

Type 1. Busbar separation is achieved by insulated covering, e.g. sleeving,

wrapping or coatings.

Type 2. Busbar separation is by metallic or non-metallic rigid barriers or

partitions