Furse, Wilford Road, Nottingham, NG2 1EB • Tel: +44 (0)115 964 3700 • Email:

enquiry@furse.com• Web:

www.furse.comFurseWELD

TSC-0912 - 09.10.12

1

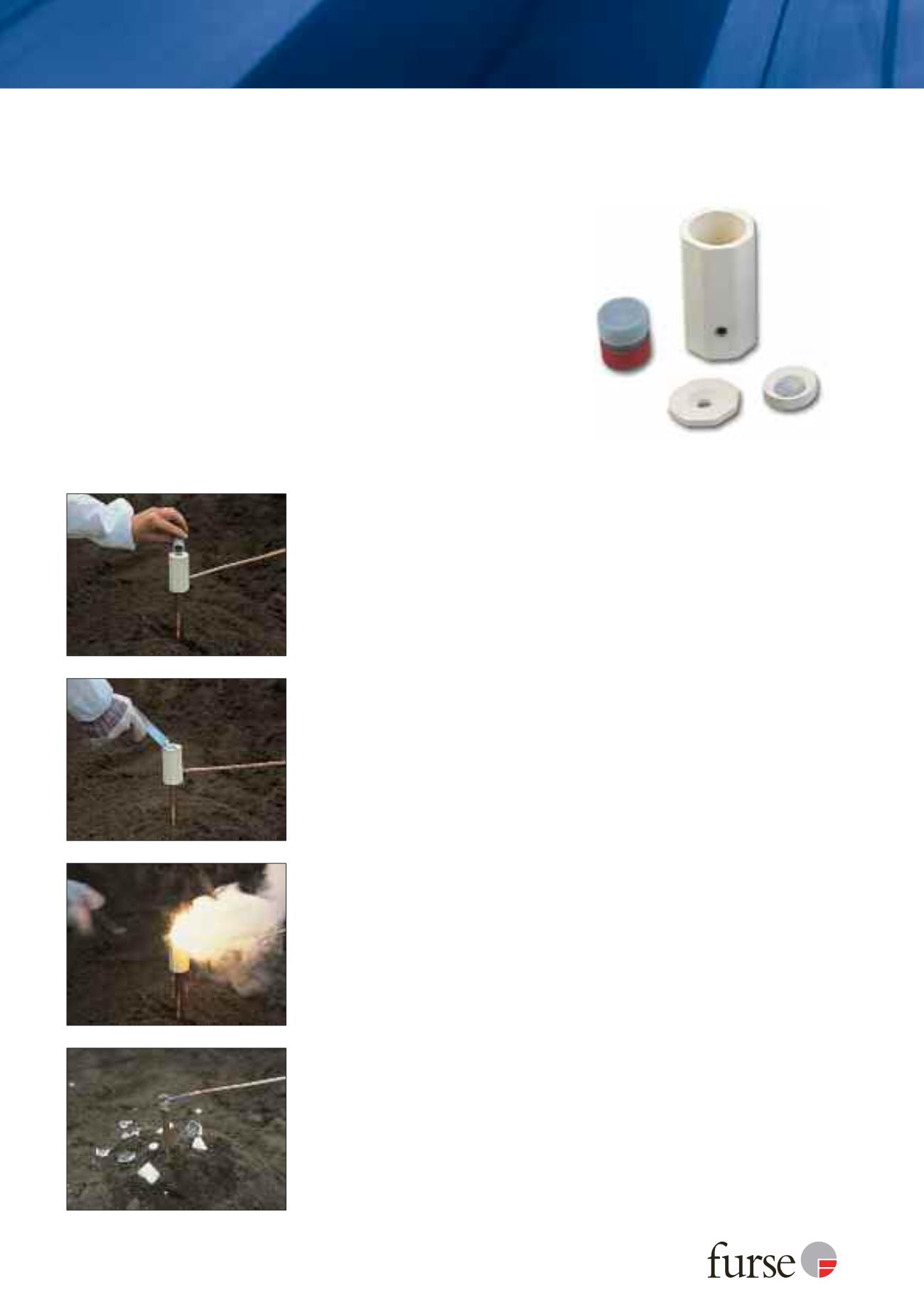

Insert the rod and conductor into the mould, locate the retaining disc and

pour in the weld powder.

2

Place the lid on top of the mould, add starting powder and ignite with

spark gun.

3

The resulting exothermic reaction reduces the weld powder to molten

copper alloy which melts the retaining disc and flows into the weld cavity

where it partially melts the conductors. The molten copper alloy cools to

leave a fusion weld of great mechanical and electrical integrity.

4

Once the joint is completed, the ceramic mould can either be disposed of

or buried in place.

The FurseWELD SureSHOT system is a cost effective solution for applications requiring only a small number of high

quality electrical connections.

Like all FurseWELD products, SureSHOT uses the high temperature reaction

between powdered copper oxide and aluminium to create fault tolerant

electrical connections without any external power or heat source.

SureSHOT connections have the same benefits as FurseWELD connections:

tolerant to repeated fault currents

highly conductive

do not loosen

excellent corrosion resistance

Unlike the graphite FurseWELD moulds, the SureSHOT moulds are ceramic

and specifically designed to be used only once. They are disposed of or

buried in place with the joint once it has been completed.

SureSHOT moulds are supplied complete with powders and retaining disc.