5/32

Functions

(

continued)

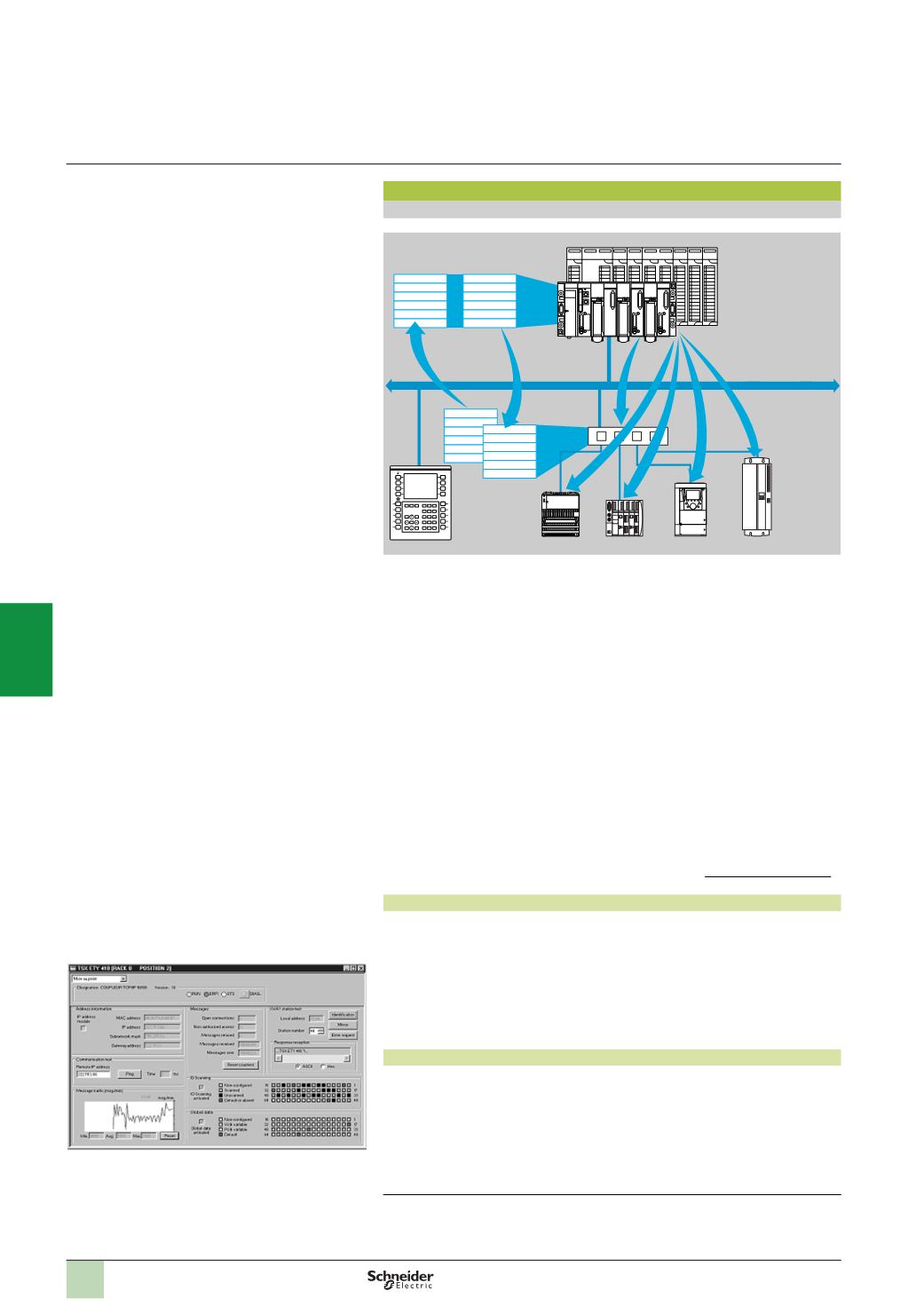

I/O Scanning service

The I/O Scanning Service is used to manage the exchange of remote I/O states on

the Ethernet network after simple configuration, with no need for any special

programming.

I/O scanning is performed transparently by means of read/write requests according

to the Modbus client/server protocol on the TCP/IP profile.

This principle of scanning via a standard protocol enables communication with any

device supporting Modbus TCP messaging in server mode.

This service can be used to define:

b

A%MW word zone reserved for reading inputs

b

A%MW word zone reserved for writing outputs

b

Refresh periods independent of the PLC scan

During operation, the module:

b

Manages TCP/IP connections with each remote device

b

Scans devices and copies the I/O to the configured %MW word zone

b

Feeds back status words used to check that the service is working correctly from

the PLC application

b

Applies pre-configured fallback values if a communication problem occurs

A range of hardware and software products is available enabling the I/O Scanning

protocol to be implemented on any type of device that can be connected to the

Ethernet network. Please consult the Modbus-IDAwebsite:

www.modbus-ida.org.

Characteristics

b

Under Unity Pro software, each station can exchange a maximum of:

v

100

write words

v

125

read words

b

Maximum size in the PLC managing the service:

v

2

Kwords %MW

(1)

in inputs and 2 Kwords %MW

(1)

in outputs with manager

PLC limited to 64 stations

v

4

Kwords %MW

(1)

in inputs and 4 Kwords %MW

(1)

in outputs with manager

PLC limited to 128 stations

I/O Scanning service diagnostics

I/O Scanning service diagnostics can be performed in one of five ways:

b

Via the application program from a specific PLC data zone

b

From the setup software debug screen

b

From the PLC system diagnostic function displayed by means of a web browser

on a PC station

b

Using the

TSX EAZ 01P SFE10

ConneXview diagnostic software

b

Using standard SNMP network management software

(1)

or 4x registers with Concept or ProWORX.

INPUT

OUTPUT

+

–

INPUT

OUTPUT

+

–

A

B

A

B

Word table

Read

Write

Ethernet

Modbus/TCP

Device

input words/

output words

Functions

(

continued)

Modicon Premium or

Modicon Quantum

platform with I/O Scanner

function (Transparent

Ready class

p

30)

Device with

Modbus/TCP

messaging in

server mode

I/O Scanning service diagnostics

Modicon Premium automation

platform

0

Ethernet Modbus/TCP network

Ethernet Modbus/TCP communication services

2

1

3

4

5

6

7

8

9

10