11 Moulded Case Breakers 0115

ABB Low Voltage

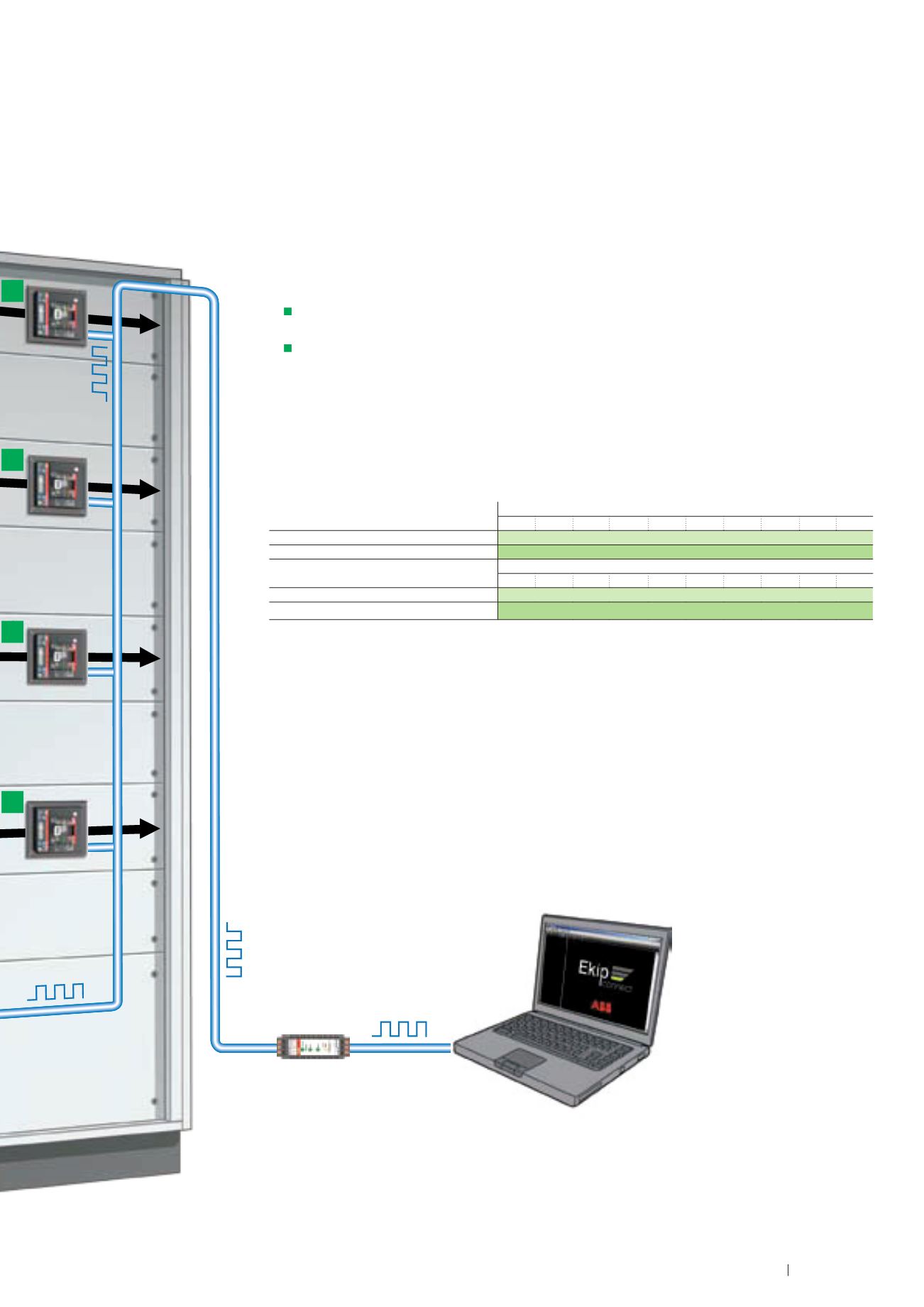

Converter

RS-232/RS-485

Modbus RTU

ABB |

SACE Tm x Mould d-case circuit-breakers 9

Circuit-breakers for energy measurement and communication

5

5

5

5

A low voltage electrical installation is similar to an industrial process for electricity distribution

and needs a supervisory and monitoring system that is able to increase reliability and optimize

management.

To achieve integration between conventional plant engineering techniques and control sys-

tems for the purpose of running, controlling and monitoring civil and industrial installations in a

centralized and automatic way, one can consider the electrical installation as being affected by

two flows:

n

a main flow (energy flow) formed by the power and energy supplied to the users and loads

of an installation through the line conductors and control and protection devices;

n

an information flow (digital flow) formed by all the information, data and commands required

to control and manage the installation.

The supervisory system handles the flow of information that transits through the communica-

tion network.

In this type of installation, the circuit-breaker acts as both sensor and actuator. As a sensor,

it collects sensitive information and data and sends them to the supervision system. As an

actuator, it executes the command received from the control device (e.g. PC or PLC).

These characteristics are of particular importance since they meet the growing demands for

circuit-breaker integration into latest generation networks (Smart Grid).

Trip units

Frame [A]

160 250 400 500 630 800 1000 1600 2500 3200

LSI (Advanced electronic trip unit)

Tmax XT2-XT4-T4-T5-T6-T7-T8

LSIG (Advanced electronic trip unite)

Tmax XT2-XT4-T4-T5-T6-T7-T8

Functions

Frame [A]

160 250 400 500 630 800 1000 1600 2500 3200

Energy measurement

Tmax XT4-T4-T5-T6-T7-T8

Supervision and Monitoring

Tmax XT4-T4-T5-T6-T7-T8

A low voltage electrical installation is similar to an industrial process for electricity distribution

and needs a supervisory and monitoring system that is able to increase reliability and optimize

management.

To achieve integration between conventional plant engineering techniques and control systems

for the purpose of running, controlling and monitoring civil and industrial installations in a

centralized and automatic way, one can consider the electrical installation as being affected by

two flows:

a main flow (energy flow) formed by the power and energy supplied to the users and loads

of an installation through the line conductors and control and protection devices;

an information flow (digital flow) formed by all the information, data and commands required

to control and manage the installation.

The supervisory system handles the flow of information that transits through the communication

network.

Circuit-breakers for energy measurement and communication

In this type of installation, the circuit-breaker acts as both sensor and actuator. As a sensor,

it collects sensitive information and data and sends them to the supervision system. As an

actuator, it executes the command received from the control device (e.g. PC or PLC).

These characteristics are of particular importance since they meet the growing demands for

circuit-breaker integration into latest generation networks (Smart Grid).

Trip unit

Frame [A]

160 250 400 500 630 800 1000 1600 2500 3200

LSI (Advanced electronic trip unit)

Tmax XT2-XT4-T4-T5-T6-T7-T8

LSIG (Advanced electronic trip unite)

Tmax XT2-XT4-T4-T5-T6-T7-T8

Functions

Frame [A]

160 250 400 500 630 800 1000 1600 2500 3200

Energy measurement

T

T4-T4-T5-T6-T7-T8

Supervision and Monitoring

Tmax XT2-XT4-T4-T5-T6-T7-T8

5

5

5