165

n

Technical information

IP 44 conforms to BS EN 60529 and IEC 60529

Icc 10 kA according to BS EN 60309-1 and IEC 60309-1

Stainless steel external screws

- Nickel plated brass contacts

IK according to BS EN 62262 and IEC 62262 : plastic = IK 09

metal = IK 10

Tightening torque of connection screws

ELV 16 A : from 1 to 1 . 2 Nm

LV 16 A : from 0 . 7 to 1 Nm

LV 32 A : from 0 . 7 to 1 Nm

LV 63 A : from 2 to 2 . 2 Nm for Phase and Earth

from 0 . 7 to 1 Nm for pilot

n

Wiring tested according to BS EN 60309-1

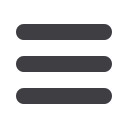

Mobile sockets IP 44

ELV 16 A, LV 16/32 A

(p. 163-164)

LV 63 A

1

(p. 164)

A

B

D

Ø

C

A

B

D

Ø

C

A

B

Ø

C

053582-20850c.eps

A

B

Ø

C

053582-20 50c.eps

Material

Weight

Dimensions (mm)

Ø Clamping

(kg)

A

B

C

D

and grip (mm)

ELV 16 A

2 P

Plastic

0·190

148

54·5

74

55

8·5 to 22

LV 16 A

2 P +

T

Plastic

0·170

147

54·5

74

55

8 to 15

3 P +

T

Plastic

0·200

151

61·5

81

60

8 to 15

3 P + N +

T

Plastic

0·245

172

69·5

90

66

10 to 18

LV 32 A

2 P +

T

Plastic

0·300

177

71

93

70·5

10 to 18

3 P +

T

Plastic

0·300

177

71

93

70·5

12 to 22

3 P + N +

T

Plastic

0·350

183

77·5

100

77

12 to 22

LV 63 A

3 P +

T

Plastic

0·770

273

96

119

–

18·5 to 29

3 P + N +

T

Plastic

0·830

273

96

119

–

20·5 to 32

Type

Current

Conductors size

Conductors

(mm

≤

)

type

ELV 16 A

4 to 10

Rigid

Surface and

LV 16 A

1 . 5 to 4

Rigid

panel mounting

LV 32 A

2 . 5 to 10

Rigid

sockets

LV 63 A

6 to 25

Rigid

ELV 16 A

4 to 10

Flexible

Straight plugs and

LV 16 A

1 to 2 . 5

Flexible

mobile sockets

LV 32 A

2 . 5 to 6

Flexible

LV 63 A

6 to 16

Flexible

ELV 16 A

4 to 10

Rigid

Panel appliance

LV 16 A

1 to 2 . 5

Rigid

inlets

LV 32 A

2 . 5 to 6

Rigid

LV 63 A

6 to 16

Rigid

Hypra

®

IP 44 - ELV 16 A and LV 16/32/63 A

m

etal and plastic plugs and sockets

n

Dimensions

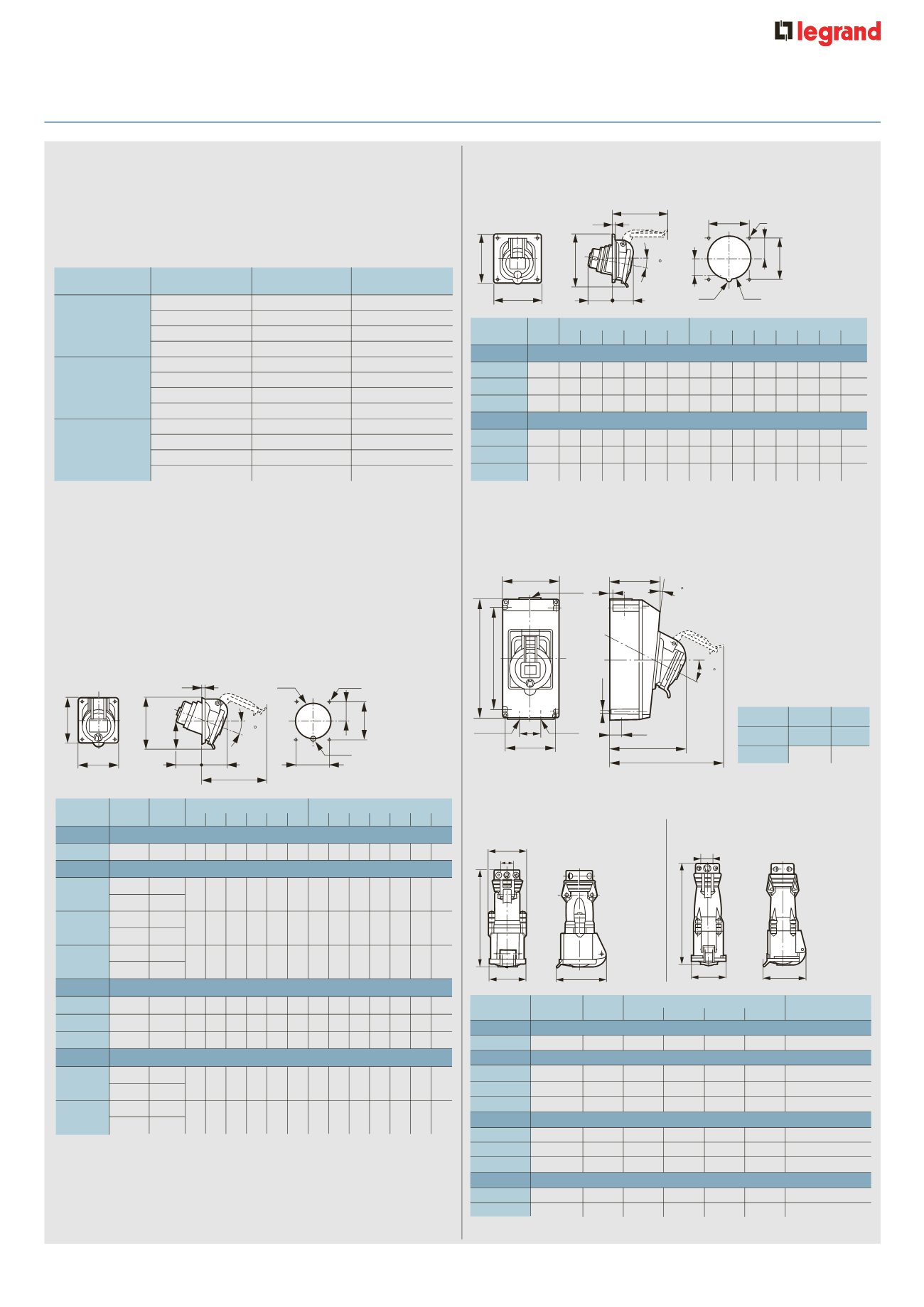

Panel mounting sockets IP 44

ELV 16 A plastic and LV 16/32/63 A plastic and metal

(p. 163-164)

F

K

E

J

H

G

20

I

A

Drilling

B

C

Ø d

Ø D

Ø T

= =

76

(63A)

051920-63255c.eps

Weight

Drilling (mm)

Dimensions (mm)

(kg) A B C Ø D Ø d d1 E

F G

H

I

J

K Ø

LV 16 A

2 P +

T

0·110 70 70 35 76·2 –

– 84 84 37 36 89 4·5 88 4·2

3 P +

T

0·140 70 70 35 76·2 –

– 84 84 43 36 97 4·5 89 4·2

3 P + N +

T

0·165 70 70 35 76·2 –

– 84 84 43 37 106 4·5 91 4·2

LV 32 A

2 P +

T

0·220 70 70 35 76·2 –

– 84 94 54 45 117 4·5 100 4·2

3 P +

T

0·220 70 70 35 76·2 –

– 84 94 54 45 117 4·5 100 4·2

3 P + N +

T

0·255 70 70 35 76·2 8 36 84 94 54 46 125 4·5 102 4·2

Material

Weight Drilling (mm)

Dimensions (mm)

(kg)

A B C ØD Ød ØT E F G H

I

J K

ELV 16 A

2 P

Plastic 0·120 52 60 30 55 – 4·2 64 72 33 47 94 5·5 78·5

LV 16 A

Plastic 0·110

52 60 28 55 14·5 4·2 64 72 41 40 94 5·5 78·5

2 P +

T

Metal 0·340

3 P +

T

Plastic 0·140

60 70 31 63·5 14·5 5·2 74 84 44 40 98 5·5 88

Metal 0·405

3 P + N +

T

Plastic 0·165

60 70 33 70·6 – 5·2 80 84 44 44 110 5·5 93

Metal 0·450

LV 32 A

2 P +

T

Metal 0·605 70 80 38 76·2 10 5·2 84 94 50 53 120 5·5 103

3 P +

T

Metal 0·605 70 80 38 76·2 10 5·2 84 94 50 53 120 5·5 103

3 P + N +

T

Metal 0·660 70 80 38 76·2 10 5·2 84 94 52 56 124 5·5 107

LV 63 A

3 P +

T

Plastic 0·640

77 85 – 92 – 6·5 106 106 98 70 160 6 129

Metal 1·000

3 P + N +

T

Plastic 0·700

77 85 – 92 – 6·5 106 106 98 70 160 6 129

Metal 1·200

120

4

30

25

181

273

270

Fix 234

130

Fix 117

M 20

M 32

50

M 32

5

Ø 5 . 3

Surface mounting sockets IP 44

LV 63 A

(p. 164)

Boxes can be rotated to aid entry

Material Weight

(kg)

63 A

3 P +

T

Plastic

1·50

A

E

B

F

C

d1

K

G H

J

I

10

Drilling

Ø D

Ø d

Ø

052019-57802c.eps

Panel mounting sockets IP 44

LV 16/32 A plastic with modular fixings

(p. 163-164)

1 : Wiring diagram for 63 A shown on p. 167