GENERAL TECHNICAL DATA

15

PVCu is used for the production of extrusions and mouldings and is universally accepted

as having the most suitable properties for use within the electrical industry.

Standards and Approvals

All Gilflex PVCu products are manufactured in accordance with the requirements of BS

4678: Part 4 and BS 4662. The PVCu material used has been tested by an approved

laboratory in accordance with the requirements of the following British Standards: BS

4607: Part 1, BS 6099-2-2, BS 476: Part 7. Copies of test certificates are available upon

request. Gilflex has been awarded ISO 9002 accreditation. Trunking and conduit systems

can be installed to comply with all relevant requirements of the latest edition of the

(BS7671) IEE Wiring Regulations.

CE marking

All relevant Gilflex products in this brochure are CE marked, confirmation that they meet

the EMC and LV directives.

Performance (Strenth)

Impact resistance

High impact resistance under normal climatic

conditions, BS4678: medium duty

Charpy notched impact strength 25 kJ/m2

Tensile strength

at yield 34.62 N/mm

2

at break 42.00 N/mm

2

Fire performance

The PVCu materials used in the manufacture of Gilflex products are non-flame

propagating in accordance with BS 6099 and BS 4678. Extrusion material has been tested

by an accredited laboratory in accordance with the requirements of BS 476: part 7 and

has achieved a Class 1Y classification. Moulding material has been tested by an accredited

laboratory and conforms with IEC 695-2-1 at a severity of 750ºC.

Thermal properties

All Gilflex PVCu products are designed to accommodate local thermal expansion. Fitting

instructions explain the procedure required to deal with the differential movement at the

interface with the building fabric.

Coefficient of linear expansion

5.5 x 10-5 per ºC (5mm/3000mm with a

temperature rise of 25°C)

Operating temperatures

-5º to 60ºC

Vicat softening point

81ºC

Thermal conductivity

0.19W/m/k

Electrical

PVCu is non-conductive.

Dielectric strength

40 kV/mm in DBP

17 kV/mm in tx oil

Resistivity

1014

Ω

cm

3

Biological

Resistant to vermin and termites.

Workability

All Gilflex PVCu products are lightweight and can be readily cut and drilled with hand

tools. Short component lengths can be readily incorporated, reducing wastage of

material. All covers and accessories are manufactured to fine tolerances to ensure a tight

fit with ease of removal. Stop ends are secured to the carriers. For details, see the relevant

installation guide.

Durability

All Gilflex PVCu products are stable and will maintain its performance characteristics in

accordance with the terms and conditions described above.

Maintenance

Clip-on covers with optional screw fix and interchangeable accessories provide continuous

accessibility for rewiring, extensions and modifications to an installation. Covers and

accessories can be cleaned with a damp cloth and household detergent. The surface can

be decorated with commercial paints if required.

Mechanical performance

Impact resistance under normal climatic conditions, BS 4678: medium duty.

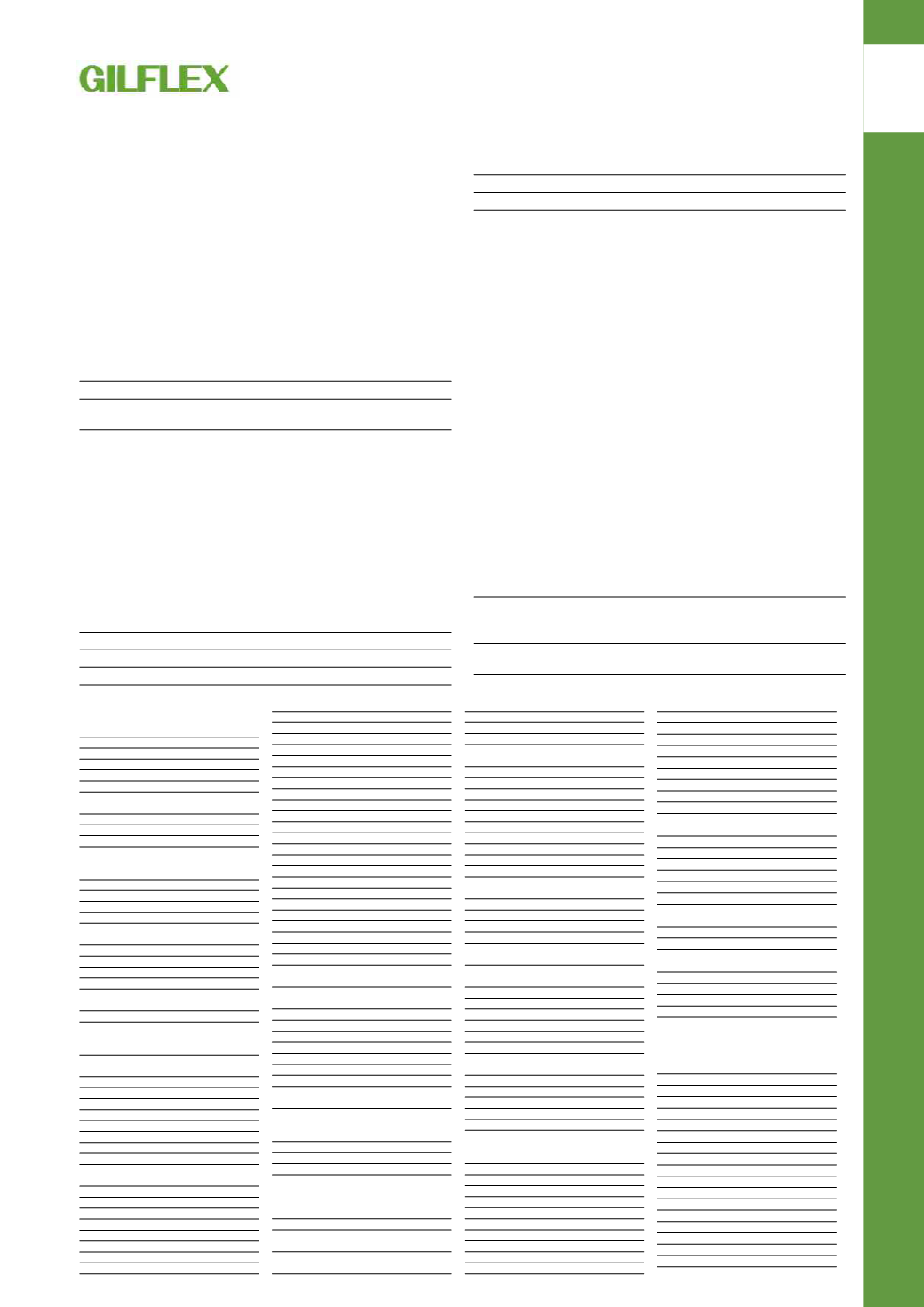

Chemical resistance (See Below)

PVCu is non-corrosive and not affected by sea water. It has excellent resistance to mineral

acids, alkalis and detergents, good resistance to alcohols, but liable to attack from

solvents such as keytones, aromatics and hydrocarbons.

Satisfactory

Some attack or absorbtion: the material may be considered for use when alternative materials

are unsatisfactory and where limited life is acceptable. When PVC is to be used with such

chemicals full scale trials under realistic conditions are necessary.

Unsatisfactory: so rated because of decomposition, solution, swelling, loss of ductility etc, of

the samples tested.

Chemical

Concentration Unplasticised PVC

20ºC 60ºC

acetaldehyde

40% aq. solution

acetic acid

60% aq. solution

acetic anhydride

acetone

Traces

alcohol, ethyl

40% w/w water

alcohol, isopropyl

alcohol, menthyl

6% aq. solution

100%

aliphatic hydrocarbons

aluminium chloride

aluminum hydroxide

ammonia

0,88S.G., aq. solution

Anhydrous gas

Anhydrous liquid

ammonium chloride

ammonium hydroxide

aniline

animal oils

aqua regia

Dilute

Concentrated

barium sulphate

beer

benzine

benzoyl chloride

borax

boric acid

brine

bromide

Traces, gas

100% (dry gas)

Liquid

calcium chloride

aq. solution

20% in methyl alcohol

calcium hydroxide

calcium hypochlorite

carbon dioxide

carbonic acid

carbon monoxide

carbon tetrachloride

castor oil

chloric acid

chlorine

100% (dry gas)

10% (moist gas)

chlorine water

Sat. solution

chloroform

chrome allum

chromic acid

Plating solution

cider

citric acid

copper chloride

copper cyanide

copper nitrate

copper sulphate

cupric sulphate

cyclohexanone

detergent, synthetic

All concentrations

developers, photographic

dextrin

dextrose

diazo salts

dichlorodifluoromethane

diethyl ether

emulsifiers

All concentrations

emulsions, photographic

ethyl acetate

ethylene glycol

ethylene oxide

fatty acids

ferric chloride

ferric nitrate

ferric sulphate

ferrous ammonium citrate

ferrous chloride

ferrous sulphate

fixing solution, photographic

fluorine

formaldehyde

40% w/w water

formic acid

50% solution

100% solution

fructose

fruit pulp

glucose

glycerol

grape sugar

heptane

hydrobromic acid

100%

hydrochloric acid

22% aq. solution

Concentrated

hydrochloric acid

40% aq. solution

60% aq. solution

Concentrated

hydrogen bromide

Anhydrous

hydrogen chloride

Anhydrous

hydrogen flouride

Anhydrous

hydrogen peroxide

3% (10vol)

12% (40vol)

30% (100vol)

90% and above

hydrogen sulphide

iodine

Solution in

potassium iodine

lactic acid

10% aq. solution

100%

lanoline

linoletic acid

linseed oil

magnesium hydroxide

maleic acid

50% aq. solution

Concentrated

metallic soaps

(water soluble)

methyl bromide

methyl chloride

methyl cyclohexanone

methyl ethyl ketone

methyl isobutyl ketone

methylated spirit

methylene chloride

milk

mineral oil

mixed acids

(sulphuric/nitric

Various proportions)

molasses

naphtha

naphtalene

nicotine

nitric acid

5% aq. solution

50% aq. solution

nitrobenzene

oleic acid

oxalic acid

oxygen

ozone

paraffin

pentane

petrol

phosphoric acid

30% aq. solution

95% aq. solution

photographic developers

potassium bromide

potassium carbonate

potassium cyanide

potassium ferricyanide

potassium hydroxide

10% aq. solution

Concentrated

potassium hypochlorite

potassium permanganate

propane

propylene glycol

propylene oxide

saccharose

sea water

silver nitrate

soap solution

sodium bicarbonate

sodium bisulphate

sodium borate

sodium bromide

sodium carbonate

sodium chlorate

sodium chloride

sodium cyanide

sodium ferricyanide

sodium ferrocyanide

sodium fluoride

sodium hydroxide

40% aq. solution

Concentrated

sodium hypochlorite 15% Cl

sodium hyposulphate

sodium nitrate

sodium peroxide

sodium silicate

sodium sulphate

sodium sulphide

25% aq. solution

Concentration

sodium sulphite

soft soap

surface active agents (All concentrations)

(emulsifiers, synthetic detergents and wetting agents)

starch

stearic acid

sucrose

sulphur

Colloidal

sulphur dioxide

Dry

Liquid

sulphuric acid

80% aq. solution

90% aq. solution

Fuming

sulphurous acid

10% aq. solution

tallow

tanning extracts

tartaric acid

transformer oil

trichloroethane

trichloroethylene

turpentine

vegetable oils

vinegar

water

wetting agents

All concentrations

wines and spirits

xylene

zinc carbonate

zinc chloride

zinc sulphide