386

DB300006

Spacial EMCsolution

Electromagnetic protected

steel enclosures

Introduction

General

The increasing presence of electromagnetic interference in industrial environments,

together with the use of equipment susceptible to such interference requires the use

of suitably protected enclosures.

In order to suppress electromagnetic interference, S3HF enclosures, due to the type

of sheet metal and special gaskets used, fulfil two functions:

b

b

Provision of adequate screening, with the effectiveness of a Faraday cage.

b

b

Ability to provide effective protection of sensitive equipment by using galvanised

sheet metal chassis, and by following recommended installation procedures.

Electromagnetic interference

Electromagnetic disruptions comprises an electrical field E generated by a differing

potentials, and a magnetic field M, caused by current circulation, which combine

to form electromagnetic field.

The electromagnetic interference or "noise" is a disruptive electrical signal which

affects the useful signal and it likely to cause a malfunction.

Interference can be carried through the conductors or emitted through the

environment.

Main sources of electrical interference and equipment

sensitive to it

b

b

Programmable controllers.

b

b

Electronic circuits or boards.

b

b

Regulators.

b

b

Input signal cables (detectors, sensors, measurement probes).

b

b

Analogue signal cables.

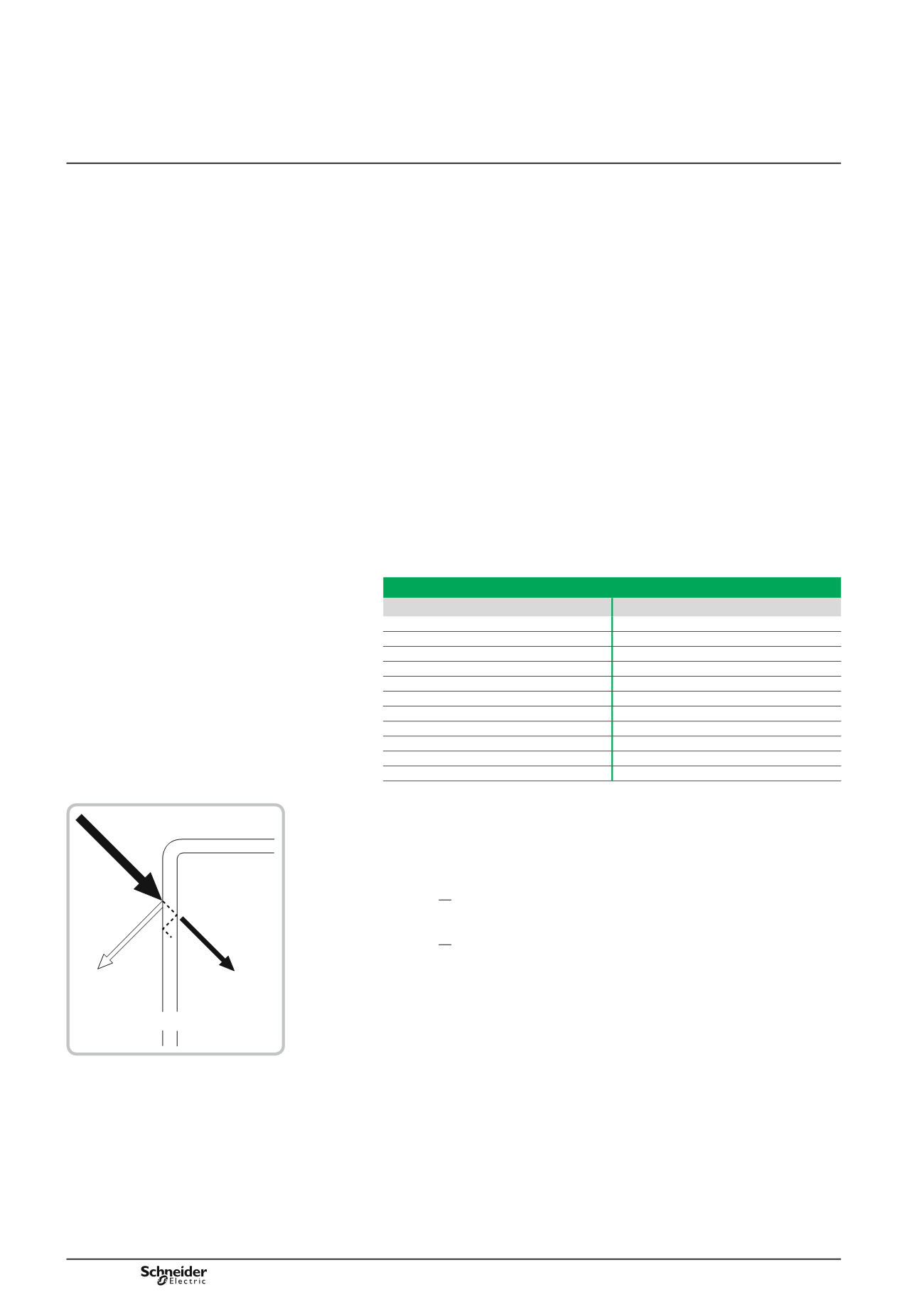

Attenuation level of EMC fields

The waves of electrical or magnetic fields are reflected when they meet the sheet

metal of the enclosure.

The effective rate of the screening or dampening "a" of the incident wave is

measured in decibels (dB) using the following formulae:

a = 20 log E

0

E

1

(dB) for electrical fields,

a = 20 log H

0

H

1

(dB) for magnetic fields,

b

b

E

0

and E

1

are the current values of the electrical field, before entering and after

entering the enclosure respectively.

b

b

H

0

and H

1

are the magnetic field values.

Main sources of electrical interference

Material

Frequency range

Motors

10 kHz… 100 MHz

Transformers/rectifiers

10 kHz… 100 MHz

Inductive load switching

50 kHz… 10 MHz

Spot welders

10 kHz… 50 MHz

Fluorescent lamps

100 kHz… 3 MHz

Relays, contactors

10 kHz… 200 MHz

Switching power sources

10 kHz… 30 MHz

Computers (internal clock)

50 kHz… 200 MHz

Variable speed drives

10 kHz… 100 MHz

Induction furnaces

0… 10 kHz

Power cables, etc.

0… 10 kHz

Reflected

wave

Enclosure surface

Outside

Inside

Incident

wave

Radiated

wave