07

Elegance Aluminium

A

ccessory boxes

• Remove appropriate knockout and

clip box into trunking base.

• For boxes in same compartment as

supply, remove appropriate knockout

and clip box into trunking base.

• When boxes are installed

consecutively, a 14mm wide length of

cover is required to cover the space

between the boxes.

• Part M box assemblies with

contrasting coloured faceplates are

available to meet the requirements of

DDA regulations for Visual Impairment.

C

overs

Covers are designed to limit

unauthorised removal and to remain in

position during normal conditions

irrespective of impact and minor

undulations of the mounting surface.

C

overs – fitting

Covers are clipped into place from front.

If accessory boxes are installed, the

LTL1/LP1010 cover is butt-joined to the

edge of the box (ESSB1/2 only). Cut

edges of the cover are concealed by the

accessory.

C

overs – removal

To remove a cover, first detach an

accessory to gain access. The main cover

can then be gently eased off the base.

S

creening

Aluminium containment will protect all

internal circuits from external

electromagnetic interference. For

internal segregation metallic dividing

fillets are avaliable.

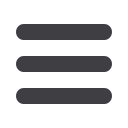

O

ffset dimensions

The minimum set that can be

accommodated in the same plane (from

internal to external bend), is 145mm.

Dimensions

Elegance 110

A = 5254mm

2

total area

A = 2365mm

2

45%

space factor

With box in comp 1

A = 2987mm

2

total area

A = 1344mm

2

45%

space factor

E

legance 170

A = 1764mm² total area

A = 794mm² 45% space

factor

Without Accessory

B = 4508mm² total area

B = 2028mm² 45% space

factor

With Accessory

B – 1748mm² total area

B = 787mm² 45% space

factor

Cable capacities

• All calculations allow for a 45% space

factor.

As there can be differences between data

cable sizes, Marshall-Tufflex recommend

that cable dimensions are confirmed with

the manufacturing company.

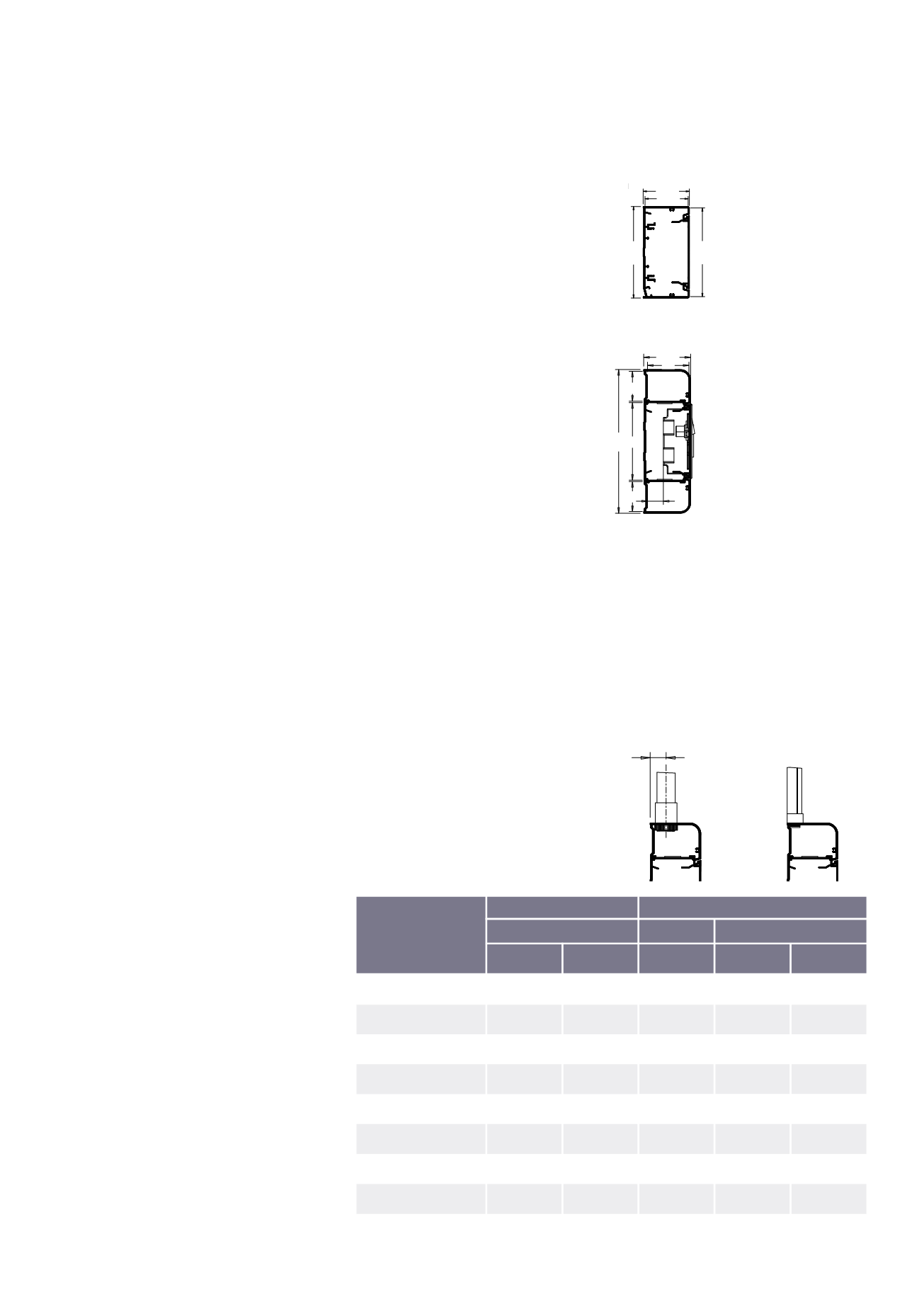

Fixing to Conduit and Mini Trunking

Elegance 170 can be used in

conjunction with Conduit and Mini

trunking systems as detailed in the

diagrams below:

Material

Aluminium trunking is manufactured from

high precision extruded aluminium with a

powder coat finish.

White RAL 9016

Silver Grey RAL 9006

Installation

Positioning

Elegance can be installed at dado level

or as a bench-mounted installation.

Fitting

• Secure trunking base every 750mm.

• Secure using No.8 round head

screws and washers using the grooves

in the outer (110) or inner (170)

compartments of the base to facilitate

drilling Ø6mm holes.

• Avoid over-tightening to permit thermal

movement.

• The use of plastic caps over screw

heads is recommended to protect

installed cables.

• To cut the trunking, use a fine tooth

blade (32/36tpi) or, preferably, a

circular saw with a 350mm diameter

fine tungsten blade (90/108tpi). This

will produce an edge requiring minimal

de-burring.

• Consecutive lengths of base are

aligned and butt jointed together.

E

arthing

• Base, covers and metallic fittings to be

cleaned of protective powder coatings

for earth bonding.

• Elegance 110. Incoming earth

connection is made using LBT1

bonding assembly installed in the earth

channel of the base.

• Elegance 170. Incoming earth

connection is made using LBT3 bonding

kit, with edge clip attached to the earth

rib in the base and faston connector

crimped to incoming earth cable.

• Bonding base to base: in final ring or

radial 32Amp circuits, bonding strap

LBS1 can be used.

• Bonding end caps to base: use

bonding strap LBS5.

• Bonding base to cover, use LBS2.

Joints and bends

• Straight lengths should be butt jointed

together with the aid of LDP1 coupler

pin if required.

• Internal bends, external bends, flat

angles and tees are prefabricated in

aluminium and butt jointed together so

cutting of base and covers has to be

very accurate to produce a good finish.

Technical Information

Cable capacity chart

Total cables =

Volume/cable factor

Elegance 110

Elegance 170

Compartment A

CompartmentA

CompartmentB

No box

Withbox

No box

Withbox

PVC power cable 1.5mmv

stranded copper

275

–

92

236

92

PVC power cable 2.5mm

2

stranded copper

188

–

63

161

62

PVC power cable 4.0mm

2

stranded copper

142

–

48

122

47

PVC power cable 6.0mm

2

stranded copper

112

–

37

96

37

Data cable: Ø5.5mm

76

–

26

65

25

Data cable: Ø6.0mm

64

–

21

55

21

Data cable: Ø6.5mm

54

18

46

18

Data cable: Ø7.0mm

48

16

41

16

55.5

55.5

107

110

52

49

19

36

36

92

170

17.5