115

3

The merits of Zinc

The Galvanic Series does show why zinc is such a useful corrosion

resistant coating for mild steel.

Firstly, it forms an impervious zinc barrier around the steel,

coating it with a metal whose own rate of chemical corrosion is

both low and predictable in most situations.

Secondly, if the coating is damaged at any point (e.g. at a cut edge)

the zinc surrounding the damaged area becomes the anode of the

electrolytic cell and is sacrificially corroded away very slowly in

preference to the underlying steel. This ensures the strength of

the steel structure remains unaffected.

Because zinc appears near the top of the Galvanic Series it will

act as a sacrificial anode in relation to most other metals; thus its

relatively low cost and the ease with which it can be applied as a

galvanised coating on steel means that it continues to be the most

commonly specified protective finish for support systems.

Life expectancy of zinc coatings

The resistance of galvanising to atmospheric corrosion depends

on a protective film which forms on the surface of the zinc. When

the steel is withdrawn from the galvanising bath the zinc has

a clean, bright, shiny surface. Over time the appearance will

change to a dull grey patina as the surface reacts with oxygen,

water and carbon dioxide in the atmosphere. A complex but

tough, stable and protective layer is formed which adheres to the

zinc. Contaminants in the atmosphere affect the nature of this

protective film.

The most significant contaminant which will accelerate the

corrosion rate of zinc is sulphur dioxide (S02) and it is the

presence of S02 which largely controls the atmospheric corrosion

of zinc.

The Zinc Millennium Map

The Galvanizers Association has undertaken significant research

based upon the positioning of reference canisters placed

throughout the UK and the Republic of Ireland to establish

background corrosion rates for 10 km

2

grids which has resulted in

the formation of The Zinc Millennium Map.

With the correct use of the map specific locations can be analysed

for average zinc corrosion rates per year.

Further information is available at

www.galvanizing.org.uk.

4

Common corrosion situations

The most common occurrences of contact between dissimilar

metals within support systems are :

a. Where stainless steel components are being fixed to a carbon

steel structure

b. Where galvanised or zinc plated components are being fixed

onto a stainless steel support system

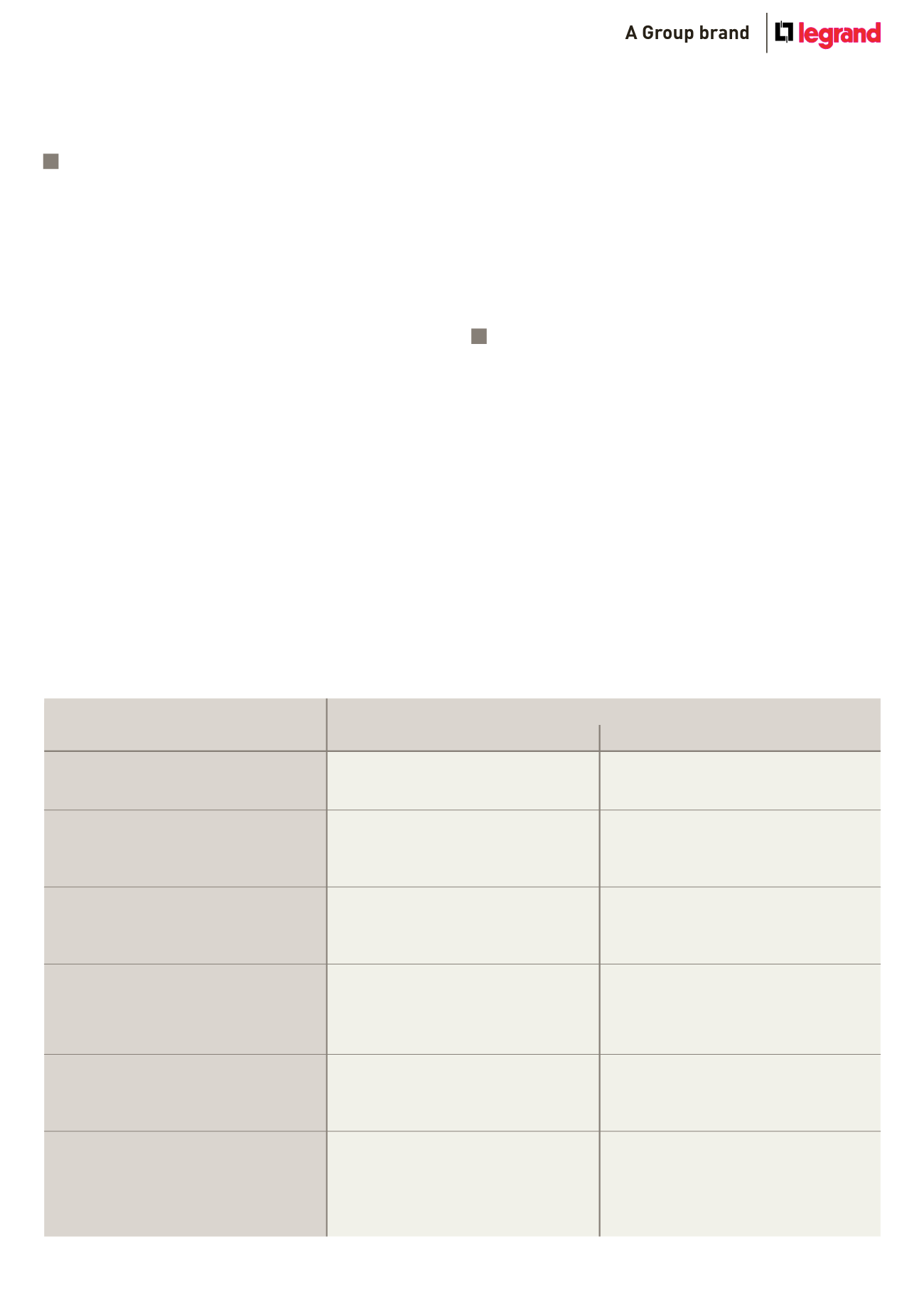

Description of typical atmospheric enviroments related to the estimation of corrosivity categories

Corrosivity category C. Corrosion rate for

zinc (based upon one year exposures),

rcorr (μm.a-1) and corrosion level

Indoor

Outdoor

Typical enviroments (examples)

C1

rcorr ² 0.1

Very low

Heated spaces with low relative humidity and

insignificant pollution, e.g. offices, schools, museums

Dry or cold zone, atmospheric environment with very

low pollution and time of wetness, e.g. certain deserts,

central Arctic / Antarctica

C2

0.1 < rcorr ² 0.7

Low

Unheated spaces with varying temperature and

relative humidity. Low frequency of condensation and

low pollution, e.g. storage, sport halls

Temperate zone, atmospheric environment with low

pollution (SO2 < 5 μg/m3), e.g.: rural areas, small

towns. Dry or cold zone, atmospheric environment

with short time of wetness, e.g. deserts, sub-arctic

areas

C3

0.7 < rcorr ² 2

Medium

Spaces with moderate frequency of condensation

and moderate pollution from production process, e.g.

foodprocessing plants, laundries, breweries, dairies

Temperate zone, atmospheric environment with

medium pollution (SO2: 5 μg/m3 to 30 μg/m3) or some

effect of chlorides, e.g. urban areas, coastal areas with

low deposition of chlorides, subtropical and tropical

zones with atmosphere with low pollution

C4

2 < rcorr ² 4

High

Spaces with high frequency of condensation and high

pollution from production process, e.g. industrial

processing plants, swimming pools

Temperate zone, atmospheric environment with high

pollution (SO2: 30 μg/m3 to 90 μg/m3) or substantial

effect of chlorides, e.g. polluted urban areas, industrial

areas, coastal areas without spray of salt water, exposure

to strong effect of de-icing salts, subtropical and tropical

zones with atmosphere with medium pollution

C5

4 < rcorr ² 8

Very high

Spaces with very high frequency of condensation and/

or with high pollution from production process, e.g.

mines, caverns for industrial purposes, unventilated

sheds in subtropical and tropical zones

Temperate and subtropical zones, atmospheric

environment with very high pollution (SO2: 90 μg/m3 to

250 μg/m3) and/or important effect of chlorides,

e.g. industrial areas, coastal areas, sheltered positions

on coastline

CX

8 < rcorr ² 25

Extreme

Spaces with almost permanent condensation or

extensive periods of exposure to extreme humidity

effects and/or with high pollution from production

process, e.g. unventilated sheds in humid tropical

zones with penetration of outdoor pollution including

airborne chlorides and corrosion-stimulating

particulate matter

Subtropical and tropical zones (very high time of

wetness), atmospheric environment with very high

pollution (SO2 higher than 250 μg/m3), including

accompanying and production pollution and/or strong

effect of chlorides, e.g. extreme industrial areas,

coastal and offshore areas with occasional contact

with salt spray