114

®

1

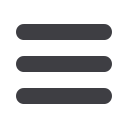

Recommended finishes for different

environments

In planning any cabling or

support installation the choice

of an appropriate corrosion

resistant finish is always a key

issue at the specification stage.

The correct choice of finish has

long term implications and is

crucial for ensuring the longevity

(and aesthetics) of the complete

installation in order to meet with

the client’s expectations.

It is vital that the finish specified

for the equipment is capable of

providing lifetime protection from

corrosion within the intended

environment - ideally with some

margin of safety.

The following pages give

information on how corrosion

occurs. Contact our technical

team on +44 (0) 845 605 5334 for

further information.

Corrosion occurs on all metals

to some extent. With some, such

as stainless steel, its effects

are usually only slight but even then the presence of certain

chemicals or physical contact with other metals may cause rapid

corrosion. It is therefore important to consider every aspect of

the environment surrounding any intended installation in order

to choose a material or finish which will minimise the risk of

damage to the support system through the effects of corrosion.

1

Chemical (atmospheric) corrosion

Few metals will suffer corrosion damage in a dry, unpolluted

atmosphere at a normal ambient temperature. Unfortunately

atmospheric pollutants are likely to be present to some degree in

most situations where support systems will be installed, thus mild

chemical corrosion is normal in almost all situations.

Any support installation which will be situated in an area where

higher concentrations of chemicals exist must receive more

detailed consideration in order to select a finish which provides

the best combination of initial cost and expected life. More

detailed information is available upon request, please contact us

on +44 (0) 845 605 5334.

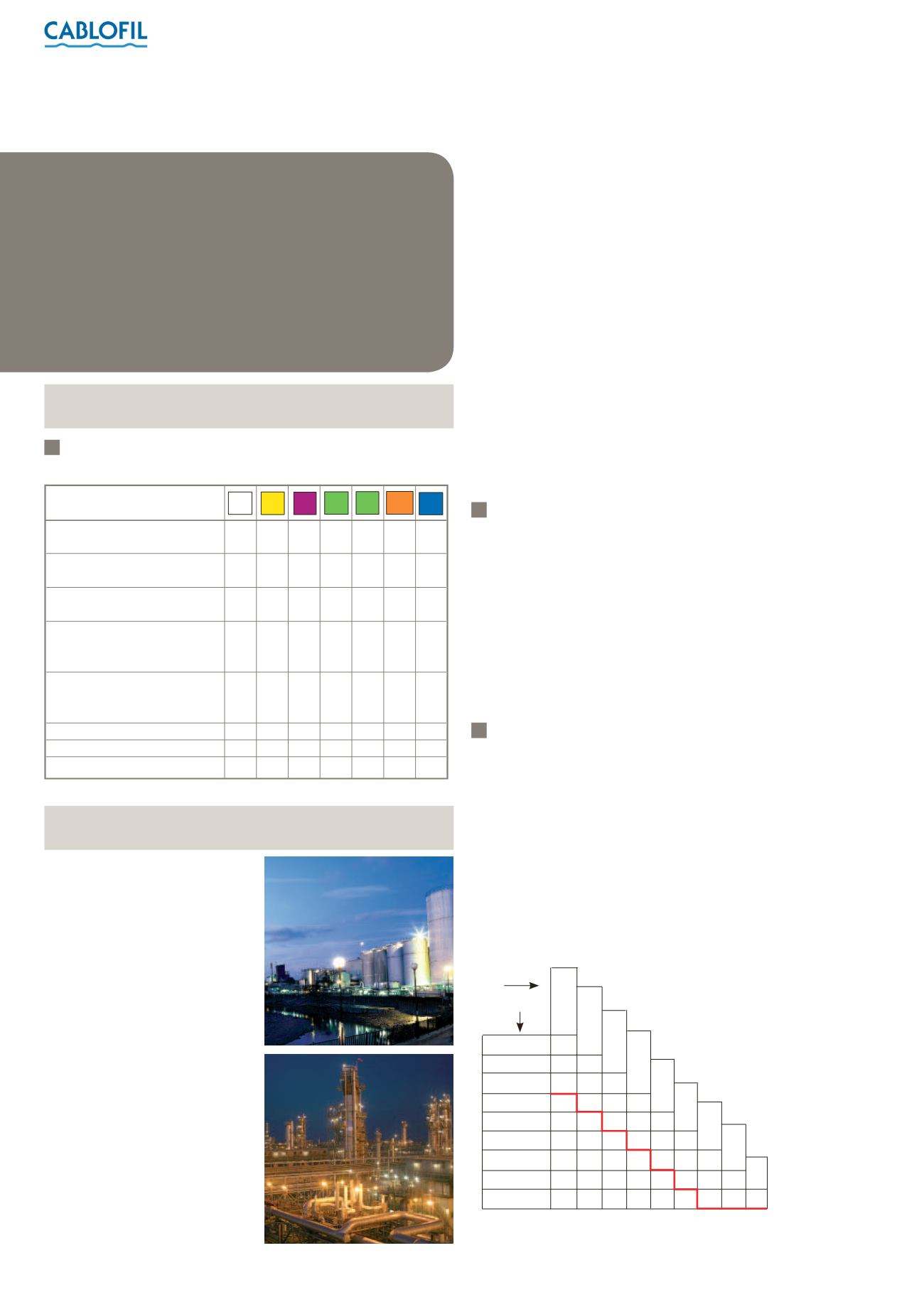

2

Electrochemical (galvanic) corrosion

When two dissimilar metals are in contact and become damp it

is possible for corrosion to be induced in one of the metals. Such

corrosion may progress rapidly and cause considerable damage

so it is important to consider and, if necessary, take steps to

eliminate this process occurring.

Electrochemical corrosion takes place because the two different

metals each behave as electrodes and the moisture as the

electrolyte in a simple battery; as with any battery the resulting

flow of current will cause corrosion of the anode.

The likely effects of this reaction can be predicted using the

Galvanic Series.

Suitability of finishes

IN THIS SECTION...

Suitability of finishes

1. Recommended finishes for

different environments

Preventing corrosion

1. Chemical (atmospheric)

corrosion

2. Electrochemical (galvanic)

corrosion

3. The merits of Zinc

4. Common corrosion

situations

Selecting the

right finish

Preventing corrosion

❍

Recommended

◆

Possible

Internal installation,

normal environment

❍

❍

External installation,

urban environment

◆

◆

◆

❍

❍

Temporary external installation

during construction phase

◆

◆

❍

Chemical industries,

nitrate explosives,

photography, decoration

◆

◆

❍

Marine, harsh, sulphurous

(weak concentration)

environments

◆

◆

❍

Acid or alkaline environments

◆

◆

◆

❍

◆

Food production environment

❍

❍

Halogen environment

◆

❍

EZ

GS

GC

DC 304L

316L

EZ+

Typical atmospheric environments in relation to suitability of finishes

Differences in potential are expressed in millivolts.

Beneath the red line, the metal involved is attacked.

Stainless steel

Stainless steel

0

Nickel

180

Copper

320 140

0

Brass

400 220

80

0

Tin

550 370 230 150 0

Steel

750 570 430 350 200

0

Aluminium

840 660 520 440 290 90

0

Chromium

950 770 630 550 400 200 110

0

Zinc

1150 970 830 750 600 400 310 200

0

Steel

Aluminium

Nickel

Copper

Brass

Partner metal

Metal involved

Chromium

Zinc

Tin