37

MR

medium rating busbar

feed units

MR is fully compliant with BS EN 60439-2

Rated currents are at an average ambient temperature of 40° C (over and above the required standard of 35° C)

IP 55 (according to BS EN 60529)

Pack

Cat. Nos.

Feed units

Metal end feed units

For plates and hole dimensions

refer to switchboard-transformer

feed units with same rating (p. 38)

Left end

Weight (kg)

Aluminium

Copper

Rating (A)

Aluminium

Copper

1

504

0

1131

160

17·74

–

1

504

0

1132

554

0

1132

250

17·76

18·47

1

504

0

1133

554

0

1133

315

17·83

18·70

1

504

0

1134

554

0

1134

400

23·22

19·58

1

504

0

1138

500

23·20

–

1

504

0

1135

554

0

1135

630

23·63

26·07

1

504

0

1136

554

0

1136

800

23·70

27·80

1

504

0

1137

554

0

1137

1 000

24·00

29·03

Right end

Weight (kg)

Rating (A)

Aluminium

Copper

1

504

0

1121

160

16·64

–

1

504

0

1122

554

0

1122

250

16·76

17·37

1

504

0

1123

554

0

1123

315

17·03

17·70

1

504

0

1124

554

0

1124

400

18·32

18·88

1

504

0

1128

500

20·00

–

1

504

0

1125

554

0

1125

630

19·43

21·17

1

504

0

1126

554

0

1126

800

19·80

23·30

1

504

0

1127

554

0

1127

1 000

20·20

24·83

Plastic end feed units

Terminals accept cables up to

150 mm

2

. For higher ratings attach

cable lugs to spreaders provided

Left end

Weight (kg)

Aluminium

Copper

Rating (A)

Aluminium

Copper

1

504

0

1111

160

6·80

–

1

504

0

1112

554

0

1112

250

6·85

7·20

Right end

Weight (kg)

Rating (A)

Aluminium

Copper

1

504

0

1101

160

5·70

–

1

504

0

1102

554

0

1102

250

5·85

6·10

Pack

Cat. Nos.

Feed units

(continued)

End feed unit with AC23 switch

disconnector

This feed unit allows isolation of

the line for maintenance

Right end up

Weight (kg)

Aluminium

Copper

Rating (A)

Aluminium

Copper

1

504

0

3401

160

17·94

–

1

504

0

3402

554

0

3402

250

18·10

19·12

1

504

0

3403

554

0

3403

315

18·86

19·40

1

504

0

3404

554

0

3404

400

21·79

20·34

1

504

0

3408

500

22·42

–

1

504

0

3405

554

0

3405

630

23·64

26·88

1

504

0

3406

554

0

3406

800

24·95

28·67

1

504

0

3407

554

0

3407

1 000

26·50

29·95

Right end down

Weight (kg)

Rating (A)

Aluminium

Copper

1

504

0

3411

160

17·94

–

1

504

0

3412

554

0

3412

250

18·10

19·12

1

504

0

3413

554

0

3413

315

18·86

19·40

1

504

0

3414

554

0

3414

400

21·79

20·34

1

504

0

3418

500

22·42

–

1

504

0

3415

554

0

3415

630

23·64

26·88

1

504

0

3416

554

0

3416

800

24·95

28·67

1

504

0

3417

554

0

3417

1 000

26·50

29·95

Left end up

Weight (kg)

Rating (A)

Aluminium

Copper

1

504

0

3421

160

17·94

–

1

504

0

3422

554

0

3422

250

18·10

19·12

1

504

0

3423

554

0

3423

315

18·86

19·40

1

504

0

3424

554

0

3424

400

21·79

20·34

1

504

0

3428

500

22·42

–

1

504

0

3425

554

0

3425

630

23·64

26·88

1

504

0

3426

554

0

3426

800

24·95

28·67

1

504

0

3427

554

0

3427

1 000

26·50

29·95

Left end down

Weight (kg)

Rating (A)

Aluminium

Copper

1

504

0

3431

160

17·94

–

1

504

0

3432

554

0

3432

250

18·10

19·12

1

504

0

3433

554

0

3433

315

18·86

19·40

1

504

0

3434

554

0

3434

400

21·79

20·34

1

504

0

3438

500

22·42

–

1

504

0

3435

554

0

3435

630

23·64

26·88

1

504

0

3436

554

0

3436

800

24·95

28·67

1

504

0

3437

554

0

3437

1 000

26·50

29·95

End stops

Ensure IP 55 protection at the end

of the run

For right and left feed units

1

50403101

160 – 315 A - for aluminium

250 – 400 A - for copper

1

50403102

400 – 1000 A - for aluminium

630 – 1000 A - for copper

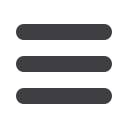

Feed unit

left end

Right end up feed

unit with AC23 switch

disconnector

End stop

Feed unit

right end

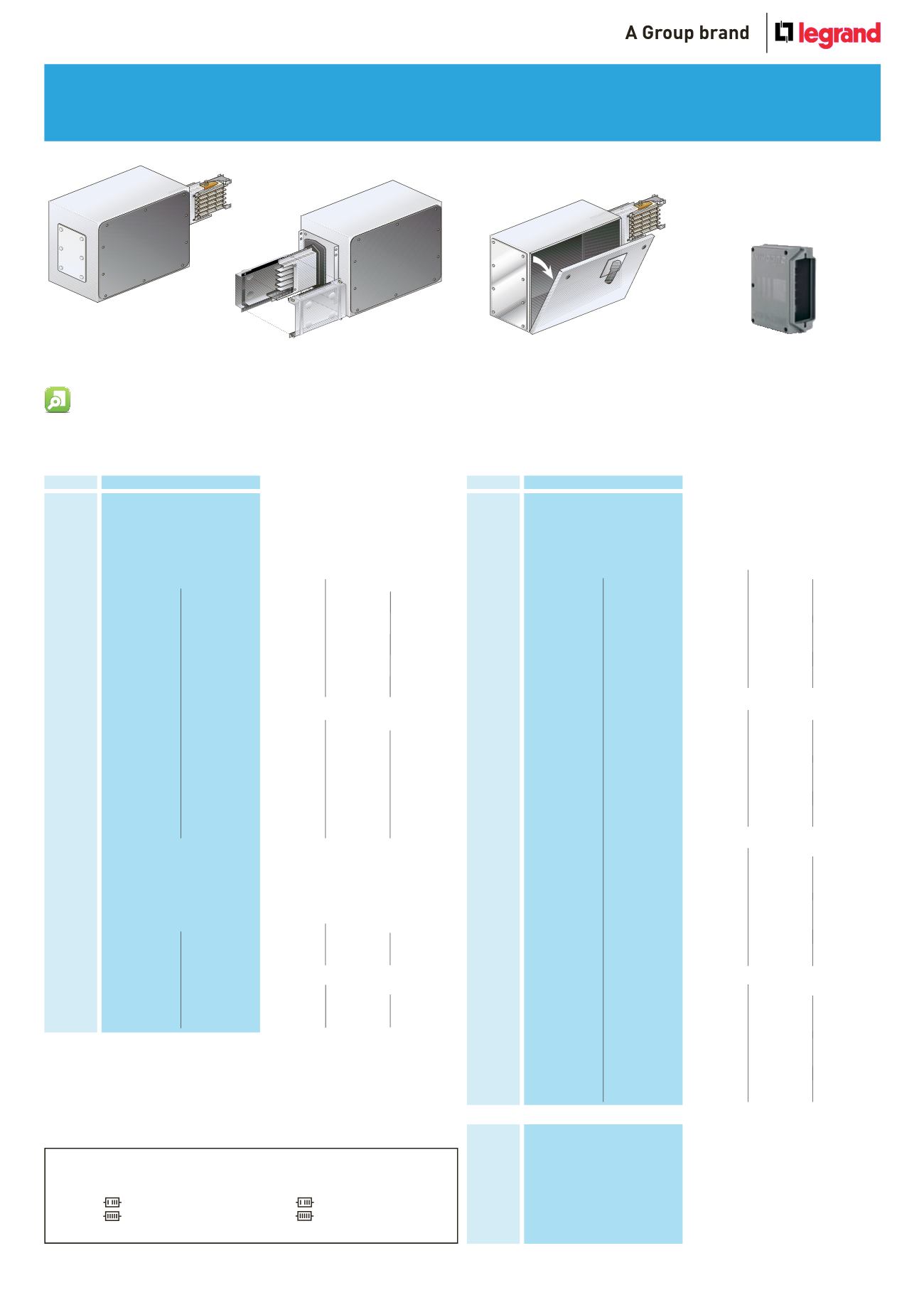

Key : How to select the correct configuration and finish

All examples on this page show 4 conductor galvanised lengths

No. of conductors and finish is dictated by the

red

number

0

= 4 conductors. Galvanised

2

= 4 conductors. Painted

1

= 5 conductors. Galvanised

3

= 5 conductors. Painted

Replace

0

with

1

,

2

, or

3

if required

4

5

- - -

0

- - - -

- - -

1

- - - -

- - -

2

- - - -

- - -

3

- - - -

Codes table

Conductors Case

Code

Painted

Painted

Galvanized

Galvanized

MR

MRF

MR-P

MRF-P

-

-

t l

t

i t

i t d

l

i

l

i

4

5

- - -

0

- - - -

- - -

1

- - - -

- - -

2

- - - -

- - -

3

- - - -

Codes table

Conductors Case

Code

Painted

Painted

Gal nized

Galvanized

MR

MRF

MR-P

MRF-P

-

-

-

t l

n t r

P i t

i t

l

i

G l

i

-

-

Dimensions and technical information p. 45 Measuring bespoke dimensions p. 49