Switch Disconnectors

3LD Main Control and EMERGENCY-STOP Switches up to 250 A

Introduction

7/4

Siemens LV 10 · 2014

7

■

Design

Design of the contacts

Each switch has three adjacent contact elements

1)

. A fourth

leading contact for switching the N conductor, a continuous

PE terminal, an auxiliary switch (1 NO + 1 NC) can be fitted to

each side of the switch. The auxiliary switches operate as

leading contacts on opening. On opening, the NO contact

opens before the main contacts, so that a contactor carries the

switching capacity in the circuit and the maintenance or safety

switch switches at zero current. On closing, the auxiliary switch

switches later than or at the same time as the main contacts.

Construction of rotary operating mechanisms

The rotary operating mechanisms of the switches for front or

floor mounting are mounted on control cabinet doors, front or

side panels with four-hole or center-hole mounting with a stan-

dard diameter of 22.5 mm and operated from the outside. In their

Off position, they can be locked with up to three padlocks with a

hasp thickness of 8 mm. Controls with defeatable door-coupling

rotary operating mechanism are available in addition.

• Switch position indicator:

The switch position is clearly marked with direction arrows and

an "O" for OFF and a "I" for ON at the front.

• Switches for front mounting:

The switches for front mounting are connected directly to

the rotary operating mechanism through the fixing screws or -

in the case of center-hole mounting - a special-purpose

coupling.

• Switches for floor mounting:

The switches for floor mounting are snapped onto 35 mm

standard mounting rails according to EN 60715 or screw-

mounted on mounting plates. The actuators are connected to

the lower section of the switch through a door coupling, which

can be released in its zero position, and a 300 mm long switch

shaft. When the control cabinet door is open, the switch can

be protected against inadvertent operation by removing the

switch shaft from the lower section of the switch.

The mounting depth can be adapted to individual require-

ments by adjusting the switch shaft length.

• Switches for distribution board mounting:

The switches for distribution board mounting are suited for

operation in distribution boards and for switching inside

control cabinets or distributors. They have cap and mounting

dimensions according to DIN 43880 and can be fitted under

the same cover together with miniature circuit breakers. The

selector switches can be locked in their OFF position with up

to 2 padlocks with a hasp thickness of 6 mm.

• Switches in molded-plastic enclosure:

For surface mounting of individual main control and

EMERGENCY-STOP switches, molded plastic-enclosed

switches to degree of protection IP65 are used. The actuators

can be locked in their OFF position with three padlocks with a

hasp thickness of 8 mm.

The molded-plastic enclosures each contain an N and/or

a PE terminal.

1)

16 A versions have four contact elements; 3-pole changeover switches

and 6-pole main control switches have six contact elements.

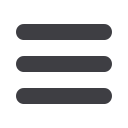

3LD2704-0TK53

switch for front mounting

with rotary operating mechanism

3LD2222-0TK1

switch for front mounting

with knob

3LD2122-7UK01 3-pole changeover

switch for front mounting with knob

3LD2103-3VK53 6-pole switch

for front mounting with rotary

operating mechanism

3LD2144-0TK53 switch for floor

mounting with rotary operating

mechanism and door coupling

3LD2530-0TK11 switch for

distribution board mounting

with knob

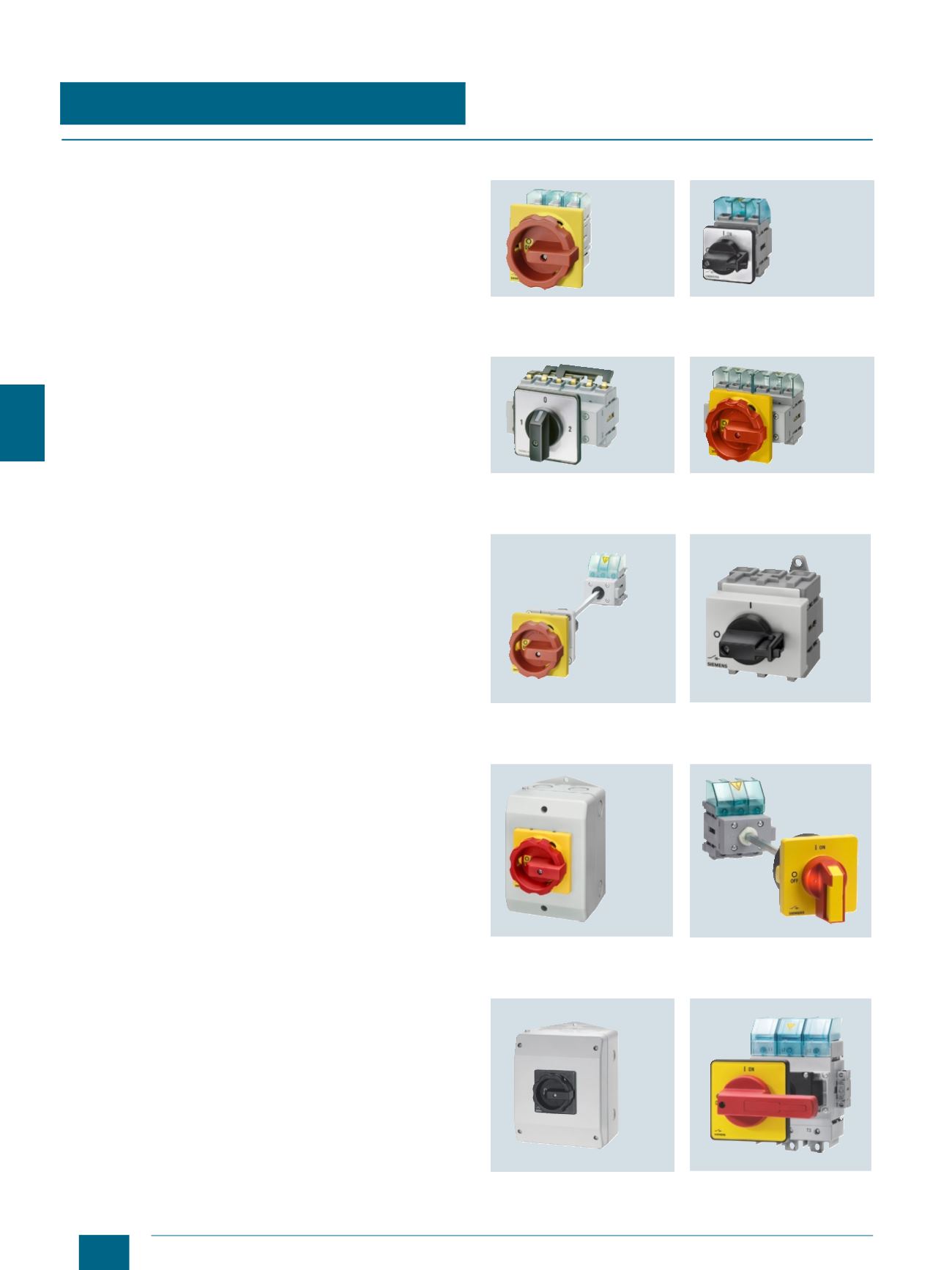

3LD2264-0TB5 switch in

molded-plastic enclosure

3LD2217-1TL13 switch for floor

mounting with rotary operating mech-

anism and defeatable door coupling

3LD2265-8VQ51-0AF6

solar plant isolator

3LD2418-0TK13 switch for floor

mounting, 250 A, with rotary operat-

ing mechanism and door coupling

© Siemens AG 2014