2010 CA08103002Z-EN

www.eaton.comCam switches, switch-disconnectors

Switch-disconnectors – safety switches

Without emergency switching off/

emergency stop function

2)

Surface mounting

IP65

Part no.

Article no.

Price

See price

list

Std. pack

Notes

P1-25/I2-SI-SW

3)

207309

1 Off

P1-32/I2-SI-SW

3)

207330

P3-63/I4-SI-SW

3)

207362

P3-100/I5-SI-SW

3)

207387

P1-25/I2-SI/HI11-SW

3)

207311

P1-32/I2-SI/HI11-SW

3)

207332

P3-63/I4-SI/HI11-SW

3)

207364

P3-100/I5-SI/HI11-SW

3)

207389

P1-25/I2-SI/N-SW

3)

207313

P1-32/I2-SI/N-SW

3)

207334

P3-63/I4-SI/N-SW

3)

207366

P3-100/I5-SI/N-SW

3)

207391

T5B-3-8342/I4-SI-SW

4)

207251

T5-3-8342/I5-SI-SW

4)

207448

T5B-4-15682/I4-SI-SW

4)

207255

T5-4-15682/I5-SI-SW

4)

207286

T5B-4-8903/I4-SI-SW

4)

207259

T5-4-8903/I5-SI-SW

4)

207290

Engineering

Maintenance, repair and safety switches all have

the same electrical function. They are designed to

safely isolate electrical installations (loads) from

mains power during maintenance and repair work

and to ensure that a hazard does not arise which

endangers personnel, machinery and production

materials.

A safety switch is an additional enclosed main

switch = isolator dedicated to an individual

electrical load and mounted in the immediate

vicinity of the motor or the electrical load.

This is particularly important if there is any danger

of the main switch being inadvertently operated.

Application

By using his padlock (up to 3), each fitter/electrician

involved can protect themselves by preventing

unauthorized personnel from switching the unit on.

Maintenance/manual override switches are simply

additional enclosed main switches with a

padlocking feature.

Enclosed main switch with padlocking facility

Features

• Safety switches are always housed in insulated

enclosures and have an inscription saying

"Safety Switch" on a bright orange label.

• Switches to be used for emergency stop switch-

ing have a red handle and yellow locking collar in

accordance with STOP category O (as per

IEC/EN 60204/VDE 0113).

• If the switch is not approved for emergency stop

switching, both parts will be black ("SW" part no.

suffix).

• The cover and handle are interlocked by fitting a

padlock.

Selection

The switches must be selected according to the following per-

formance specifications:

1) According to motor switching capacity, when the switch is

fitted in such a way that the operator may use it for operational

ON and OFF switching.

2) The rating data always applies to 3 poles. When the motor

rating is divided between 6 poles, such as for star-delta

switching, a 6 pole switch can be used to control 1.73 times

the rated power.

3) If the switch has a load-shedding Contact (LA), you can

select the appropriate switch according to the uninterrupted

current. The load-shedding contact is an auxiliary contact,

which is closed in the ON position and opens early when

switching off, so that a contactor located in the circuit takes

over the switching duty and the maintenance/safety switch

operates at zero load. When switching on, the load-shedding

contact closes later than or at the same time as the main con-

tacts. With P and T switches this is the N/O auxiliary contact.

4)The "ON" position can be locked with a padlock (by altering

the handle).

This is not permissible for switches with a red/yellow handle.

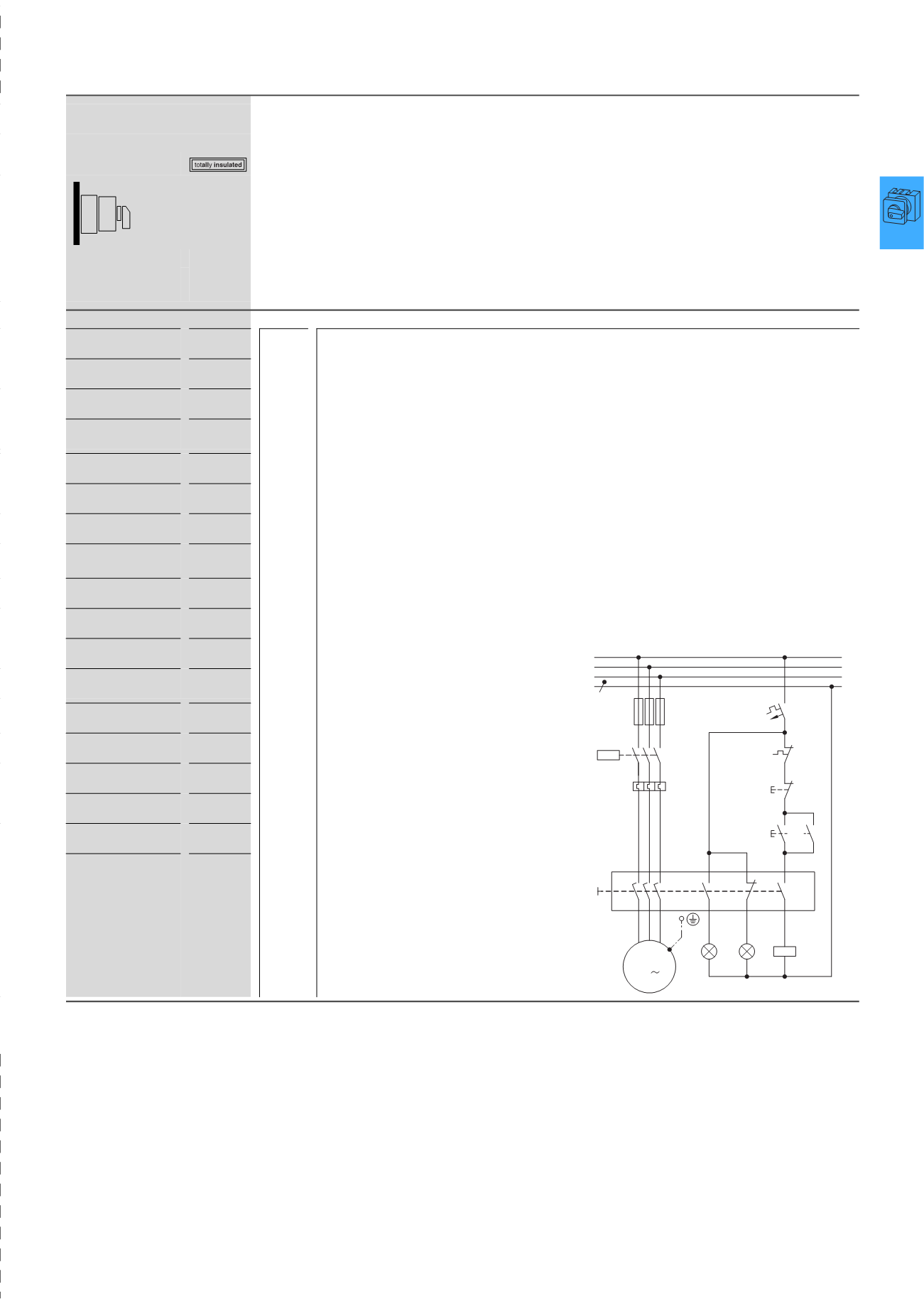

Safety switch with load shedding and signaling

Q11

L2

N

L3

L1

F1

Q11

2

1

4

3

6

5

F2

1 3 5

2 4 6

M

3

7

9

11

8

10

12

Q1

U V W

A2

Q11

A1

P1

P2

F0

95

96

21

22

F2

O

13

14

I

13

14

FAZ-

B4/1-HS

4/31

T, P

HPL04031EN