63

MCBs - Technical

Data

GENERAL CONSTRUCTION

Wylex MCBs are of the thermal-magnetic current limiting type.

MCBs have an easy to operate handle with a trip-free toggle mechanism

– so even when the handle is held in the ‘on’ position the MCB is free

to trip.

AMBIENT TEMPERATURE CONSIDERATIONS

Wylex MCBs are calibrated to meet the requirements of BS EN 60898,

30°C Ref Calibration Temperature.

At other temperatures the following rating factors should be used:

At 60°C 0.9 At 20°C 1.0 At 0°C 1.1

Adjacent thermal-magnetic MCBs should not be continuously loaded at

or approaching their nominal rated currents when mounted in

enclosures. It is good engineering practice to apply generous derating

factors or make provision for adequate free air between devices.

In these situations, and in common with other manufacturers, we

recommend a 66% diversity factor is applied to the MCB nominal rated

current where it is intended to load the MCBs continuously (in excess

of 1 hour).

METHOD OF OPERATION

1 Moderate overload conditions

Detection of moderate overload conditions is achieved by the use of a

thermo-metal element which deflects in response to the current passing

through it.The thermo-metal element moves against the trip bar

releasing the trip mechanism.

2 Short circuit conditions

When the current flowing through the MCB reaches a predetermined

level, the solenoid directly pulls in the plunger which forcibly separates

the contacts and simultaneously releases the trip mechanism.

3 Establishment of arc between fixed and moving contacts

As the moving contact moves away from the fixed contact, an arc is

established.The arc runs along the arc runner to the arc chamber

where it is split up between the plates and extinguished.

The low inertia and consequent high speed of the moving contact has a

limiting effect on the flow of fault current.The rapid development of the

arc, together with its accelerated extinction in the arc chamber,

BS EN 60898-2 gives a typical operating time of 3.5-5 milliseconds for

a type B curve MCB.

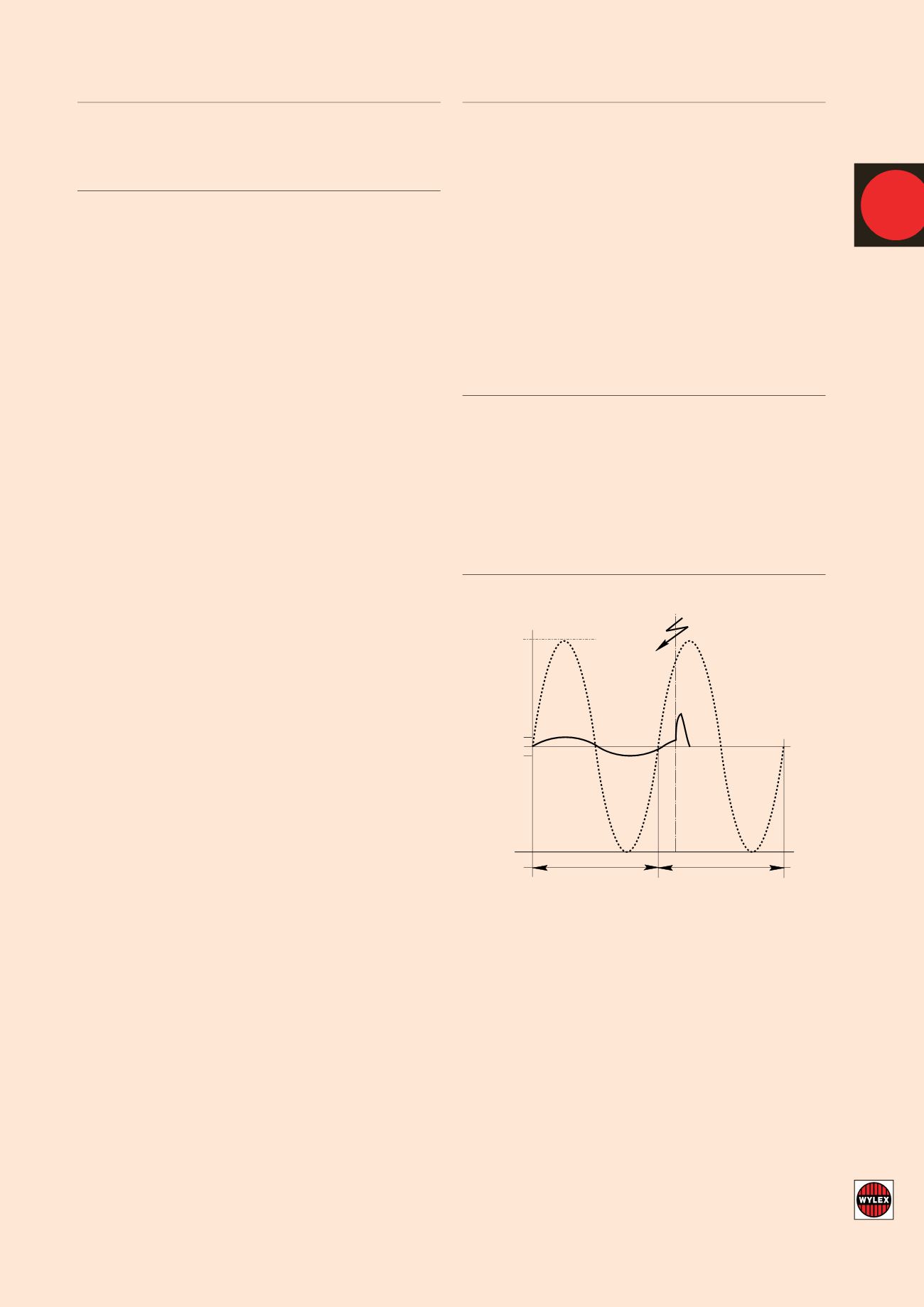

CURRENT LIMITING ACTION

The high speed current limiting action ensures that the MCB operates

before the full prospective fault current is allowed to develop.

Under fault conditions, damage can be sustained to the installation and

associated equipment due to the amount of energy that passes before

the current is completely interrupted.The total energy let-through

depends on the value of current and the time for which it flows, and is

denoted by the symbol I

2

t.The high speed current limiting action of

MCBs ensures that the energy let-through and any subsequent damage

is minimised.This reduced energy let-through assists greatly with both

back-up and discrimination considerations.

CURRENT LIMITING EFFECT

Maximum

prospective

fault

current

Healthy

circuit

current

Fault

20ms

20ms