Total Solution to Earthing & Lightning Protection |

9AKK106354A3360

2/5

2

6

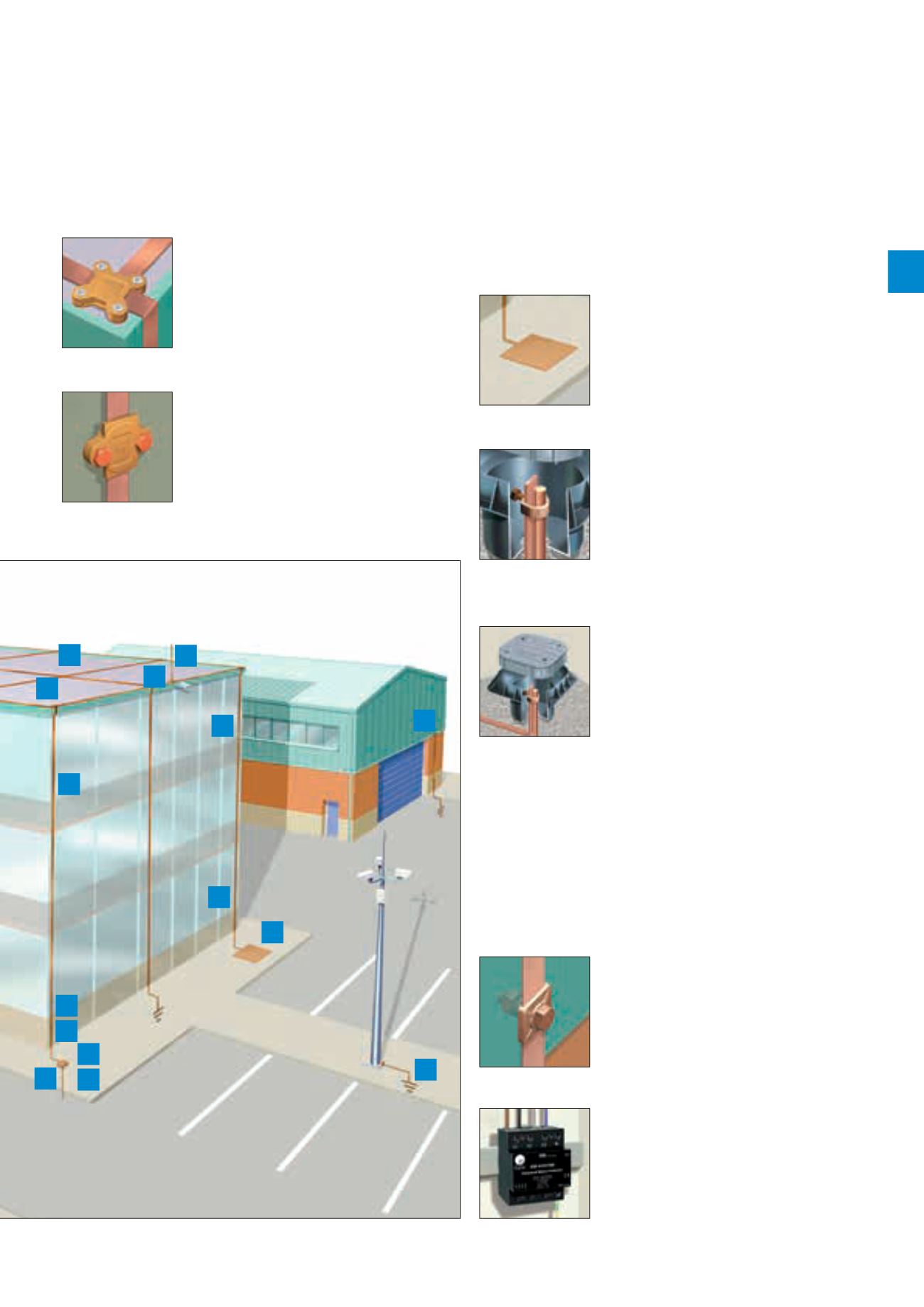

Down conductor network

6. Conductor jointing clamps

Select a component for the

interconnection of multiple conductors or

for changes of direction. Jointing clamps

will ensure a low resistance, corrosion

resistant connection between air

termination and down conductors.

7. Test clamps

In order to allow periodic disconnection

and testing of the earth termination

network, select a test clamp to be placed

within the run of each down conductor.

Earth termination network

The means of dissipating the current to the general

mass of earth.

8. Earth electrodes

Choose an earth electrode to suit the

system design i.e. Type A, Type B or

foundation electrode. Electrodes can be

constructed individually from earth

rods, earth plates, flat tape, stranded

cable or any combination of these.

9. Earth rod clamps

Select a high copper content alloy earth

rod clamp for the connection of the

earthing conductor to the earth rod. In

this below ground application, the clamp

must ensure a good electrical contact

and resist corrosion throughout the

lifetime of the installation.

10. Earth inspection pits

Select an earth inspection pit to protect

the earth electrode connections. High

strength pits are available in plastic

and concrete.

Equipotential bonding

Bonding is the most commonly employed method of

avoiding the damaging effects of side flashing. All continuous

metalwork should be considered for bonding. All metallic

services, e.g. cable armouring, gas, water or steam

piping, entering the building should also be bonded as

directly as possible to the earth termination network.

11. Bonds to metalwork

Select the correct type of metalwork

bond for the application, i.e. a flat

column face, a circular rainwater pipe or

a ribbed reinforcing bar.

12. Equipotential bonding SPDs

Designed to prevent dangerous sparking

caused by flashover, lightning current or

equipotential bonding SPDs must be

fitted to all metallic service lines with ‘live

cores’ entering or leaving the structure.

This illustration is designed to demonstrate the main aspects and

individual components of an external lightning protection system. It is not

intended to represent an actual scheme conforming to a particular

code of practice. The drawing is not to scale.

1

2

3

4

6

7

9

10

11

1

8

8

2

8

5

7

8

9

10

11

12