B-58

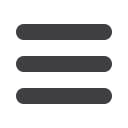

Form 2 partitioning

Distribution

Main distribution

Lateral partitioning

bb

Made of:

v

four supports that clip to the framework

v

five extruded slats that clip to the supports

v

two metal plates at the top and bottom that can be cut out to pass a PE or PEN

conductor, or one or two 30 x 60 mm trunking sections

bb

Compliance with standard IEC 695.2.1 concerning withstand to fire.

Side barrier

Restoration kit

Front or rear barrier

Dd383712.eps

DD385402.eps

Dd383714.eps

Dd381588.eps

Dd381589.eps

DD382528.eps

W = 150 mm

W = 300 mm

Characteristics

bb

Vertical barrier made of

insulating slats

bb

can be installed on both sides of

Linergy BS or Linergy LGY

busbars

bb

The space between the slats is

sufficient for prefabricated

connections (one copper bar, 5 or

10 mm thick, or insulated flexible

bars) or for cables up to 35 mm²,

while maintaining the degree of

protection IP2X

bb

This kit enables passage of the

connection between a device >

1600 A (NW, INS) and lateral

vertical busbars.

bb

It is made up of an insulated

plate (six modules high = 300 mm)

that can be cut as required,

supplied with supports and the

necessary hardware.

bb

It can be installed at any height

in the switchboard.

Can be installed in the front and rear of the busbar compartment.

Protects against direct contact with the busbars.

This barrier is not required in front when the cubicle is equipped with

a plain or transparent door.

vv

For 800 mm cubicles :

vv

the door is systematically supplied with a barrier.

vv

the cover frame is supplied with a wicket door, W = 150 mm, on

which devices can be mounted. A front barrier is indispensable.

bb

A barrier is required at the rear of the busbar compartment in

cubicles that are 600,800 and 1000 mm deep.

Catalogue

number

04922

04924

04921

04920

DD384521.EPS

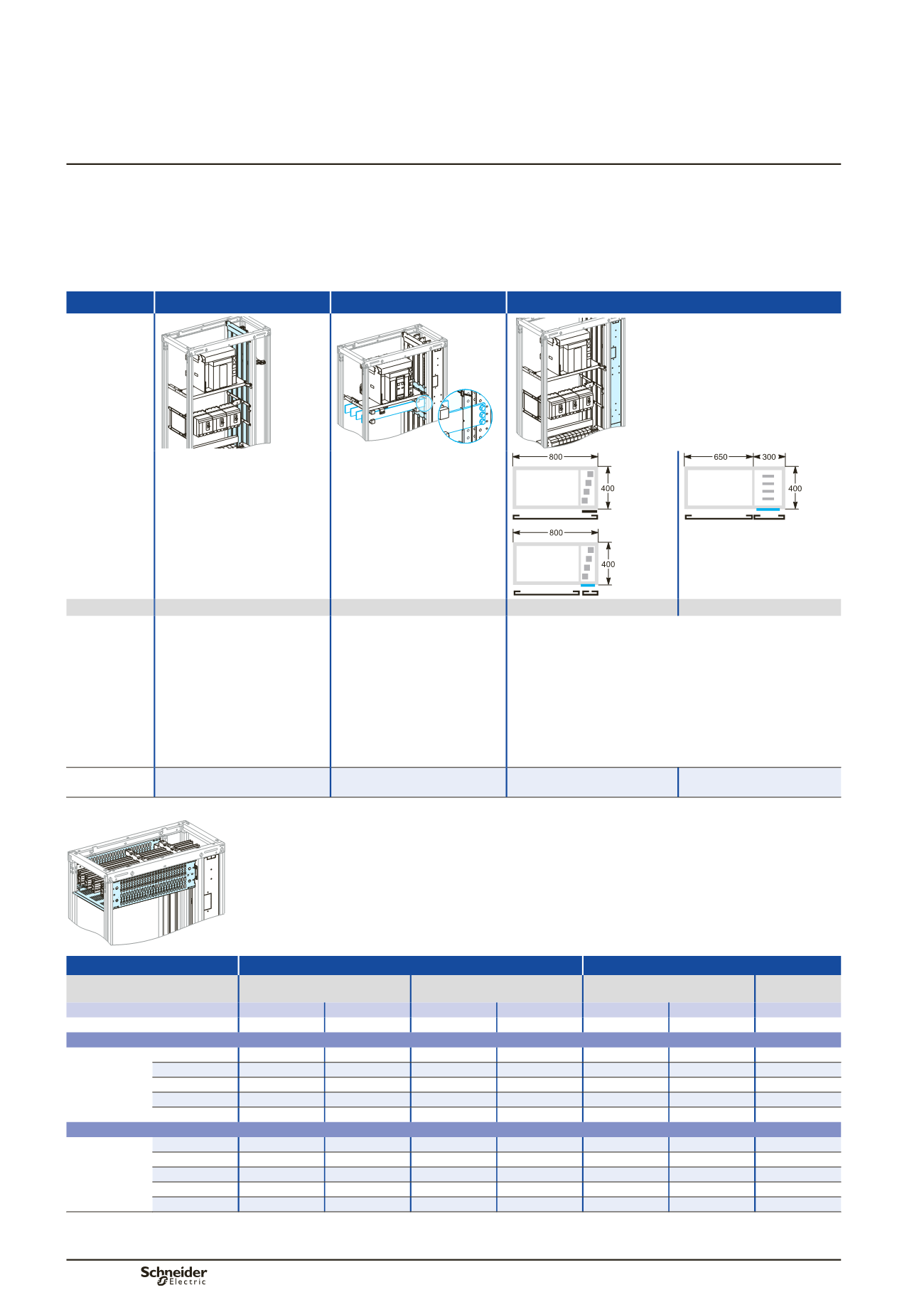

Horizontal partioning

bb

Set of two barriers (front and rear), plus a slotted rear panel for efficient natural

convection in the switchboard.

bb

The set can be used to partition horizontal busbars installed at the top or bottom

of the cubicle.

bb

The space required for the busbars is not increased.

Linergy LGYE

Linergy BS

Top position

Bottom position

Top position

Bottom

position

In

y

2500 A

u

3200 A

y

2500 A

u

3200 A

y

3200 A

4000 A

y

3200 A

Nb de modules

3

4

3

4

3

4

3

P400

Cover

W = 300

04973

04963

04973

+

04915 04963

+

04915 04973

04963

04973

+

04915

W = 400

04974

04964

04974

+

04915 04964

+

04915 04974

04964

04974

+

04915

L650

04976

04966

04976

+

04919 04966

+

04919 04976

04966

04976

+

04919

L650 + 150

04976

04966

04976

+

04919 04966

+

04919 04976

04966

04976

+

04919

L800

04978

04968

04976

+

04919 04966

+

04919 04978

04968

04976

+

04919

P600

Cover

W = 300

04983

04963

04983

+

04915 04963

+

04915 04983

04963

04983

+

04915

W = 400

04984

04964

04984

+

04915 04964

+

04915 04984

04964

04984

+

04915

L650

04986

04966

04986

+

04919 04966

+

04919 04986

04966

04986

+

04919

L650 + 150

04986

04966

04986

+

04919 04966

+

04919 04986

04966

04986

+

04919

L800

04988

04968

04986

+

04919 04966

+

04919 04988

04968

04986

+

04919

Note:

when the busbars are at the bottom of the cubicle, gland plates are mandatory, see page C-17.

Note:

To protect horizontal busbars installed at the bottom of the cubicle, the slotted slotted horizontal panel can be replaced by a plain barrier.(04915 or 04919).