198

Schneider Electric enclosures comply with standard IEC 62208 for empty

enclosures. The sheet metal used for Schneider Electric enclosures receives an

anti-corrosion epoxy electrophoresis treatment and a coating of a thermosetting,

polyester-resinmodified epoxy powder for colour and appearance.

This two-coat system provides excellent finish and corrosion protection.

The characteristics of this coating are much better than those of traditional epoxy

powders:

b

b

improved colour stability

b

b

wider operating temperature range.

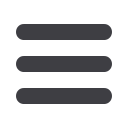

Mechanical properties of enclosures

Static load on doors, wall-mounted and floor-standing enclosures and

cubicles

Floor-standing enclosure

64 kg

Wall-mounted enclosure

48 kg

Floor-standing enclosure door

4 kg

Wall-mounted enclosure door

4 kg

Mechanical properties of powder coated surfaces

Test conditions

Test piece made of 1 mm thick steel sheet, degreased, iron phosphated, final

rinsing with 100000

W

cm DI water, 15 microns of anti-corrosion

electrophoresis treatment and 35 microns of powder paint.

Adhesion (cross-hatch and pull-off)

class 0 required (ISO 2409)

Impact strength

(1)

> 1 kg/50 cm (ISO 6272)

Mandrel bending test

(2)

< 10 mm

(ISO 6860)

Persoz hardness

300 s

(ISO 1522)

(1)

No cracking of the paint film after dropping a weight of one kilogram on the test piece from

a height of 50 centimetres.

(2)

Film cracks over a length of 10 millimetres maximum.

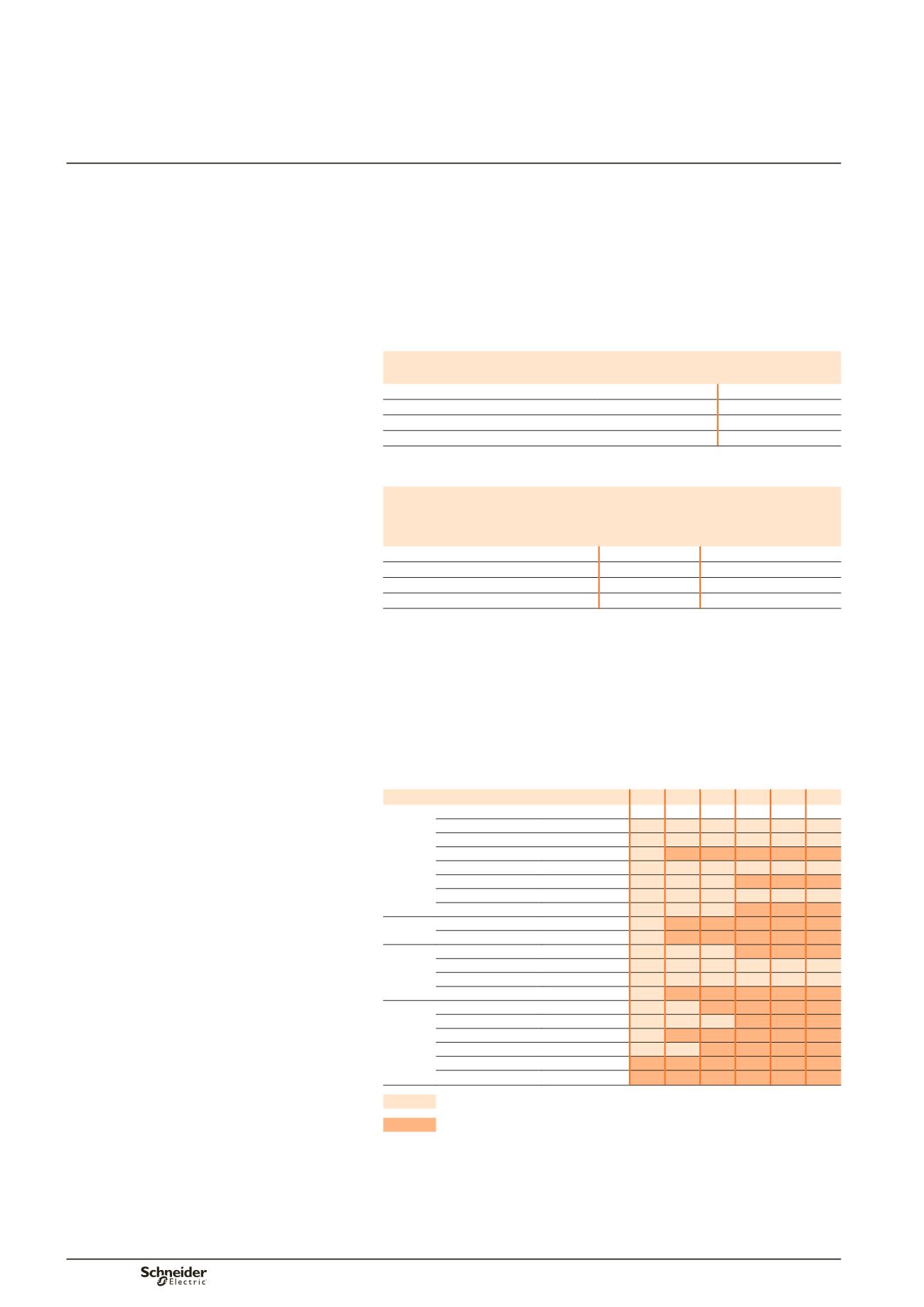

Chemical properties of powder coating

Tests carried out at ambient temperature on phosphated test pieces coated

with a 150 to 200 micron film.

Test duration (months)

2 4 6 8 10 12

Acids

Concentration

Acetic

20 %

Sulphuric

30 %

Nitric

30 %

Phosphoric

30 %

Hydrochloric

30 %

Lactic

10 %

Citric

10 %

Bases Soda

10 %

Ammonia

10 %

Water

Distilled water

Seawater

Tap water

Diluted bleach

Solvents Petrol

High alcohols

Aliphatics

Aromatics

Ketones, esters

Tri-perchlorethylene

Film intact.

Film damaged (blisters, yellowing, loss of shine).

Artificial ageing test on

powder coating

Test conditions: two tests carried out on the same

1 mm thick steel sheet test piece.

b

b

cyclical damp-heat test:

v

v

as per standard IEC 68-2-30

-- six 24-hour cycles at temperatures higher than 40 °C

b

b

continuous resistance to neutral salt mist:

v

v

the tests were carried out over a period of 400 hours,

far more than the 48 hours required by the standard for

indoor installations

v

v

as per standard IEC 68-2-11 and ISO 7253

-- 400 hours without blistering for normal surface on

test piece

-- 250 hours for a scratched surface.

Evaluation of corrosion as per ISO 4628:

b

b

adhesion: class y 1

b

b

blistering: degree 1 dim.1

b

b

rusting: Ri 1

b

b

cracking: class 1

b

b

flaking imp. 1 dim. 1

b

b

propagation of corrosion under scratch with respect

to the scratch axis: 3 mm max.

Additional information

Enclosure characteristics

Properties ofmetal enclosures