540

Technical annexes

Properties of the plasticmaterials

Mechanical, electrical, physical

and fire-resistanceproperties

Plastic materials generally used to manufacture our products:

b

b

ABS.

b

b

Polycarbonate.

b

b

PVC (polyvinyl chloride).

b

b

Bayblend

®

= PC + ABS.

b

b

Polyester reinforced with fibreglass.

b

b

Altuglas.

b

b

Polypropylene.

b

b

Polystyrene.

b

b

Polyamide 6 and 12.

b

b

SBS.

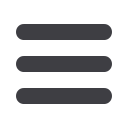

Specifications

Standards Units ABS Polycarbonate PVC

Bayblend

®

Polyester SBS

Mechanical properties

Tensile strength

ISO 257

MPa

44

> 65

45

35

85

5

Tensile strain

ISO 527

%

12

> 110

120 to 150 40

0

600

Impact resistance

ISO 179

kJ/m

2

125

No breakage

25

No breakage 60

No breakage

Notching resistance

ISO 179

kJ/m

2

19

25

20

25

50

-

Electrical properties

Stress point

IEC 60112 -

-

250-300

> 600

> 550

> 600

-

Surface strength

IEC 60093 ohm 1015

> 1015

> 1013

> 1014

≥1012

> 1013

Dielectric strength

IEC 60243 kV/mm 16.5

> 30

30

24

18-20

20

Specific resistivity

IEC 60093 ohm

cm 1015

> 1016

≥ 1015

1016

≥ 1012

> 1016

Physical properties

Softening temperature (Vicat B) ISO 306

°C

95

145-150

79-80

115

(1)

80

Temperature resistance

-

°C

-40...+90 -50...+125

-20...+65

-35...+90

-50...+150 -40...+120

Water absorption

ISO 62

%

0.2 - 0.45 0.15

< 0.1

0.2

0.2

-

Specific weight

ISO 1183

kg/dm

3

1.04

1.21

1.4

1.12

1.85

0.3 in 24 h

Fire resistance

Oxygen index

ISO 4589

%

19

26

45-50

22

24.4

18

Glow wire resistance, 2 mm

IEC 60695-2 °C

650

960

960

750

960

750° (1.5 mm)

Glow wire resistance, 3 mm

IEC 60695-2 °C

650

960

960

750

960

NA

(1) No softening of the polyester.

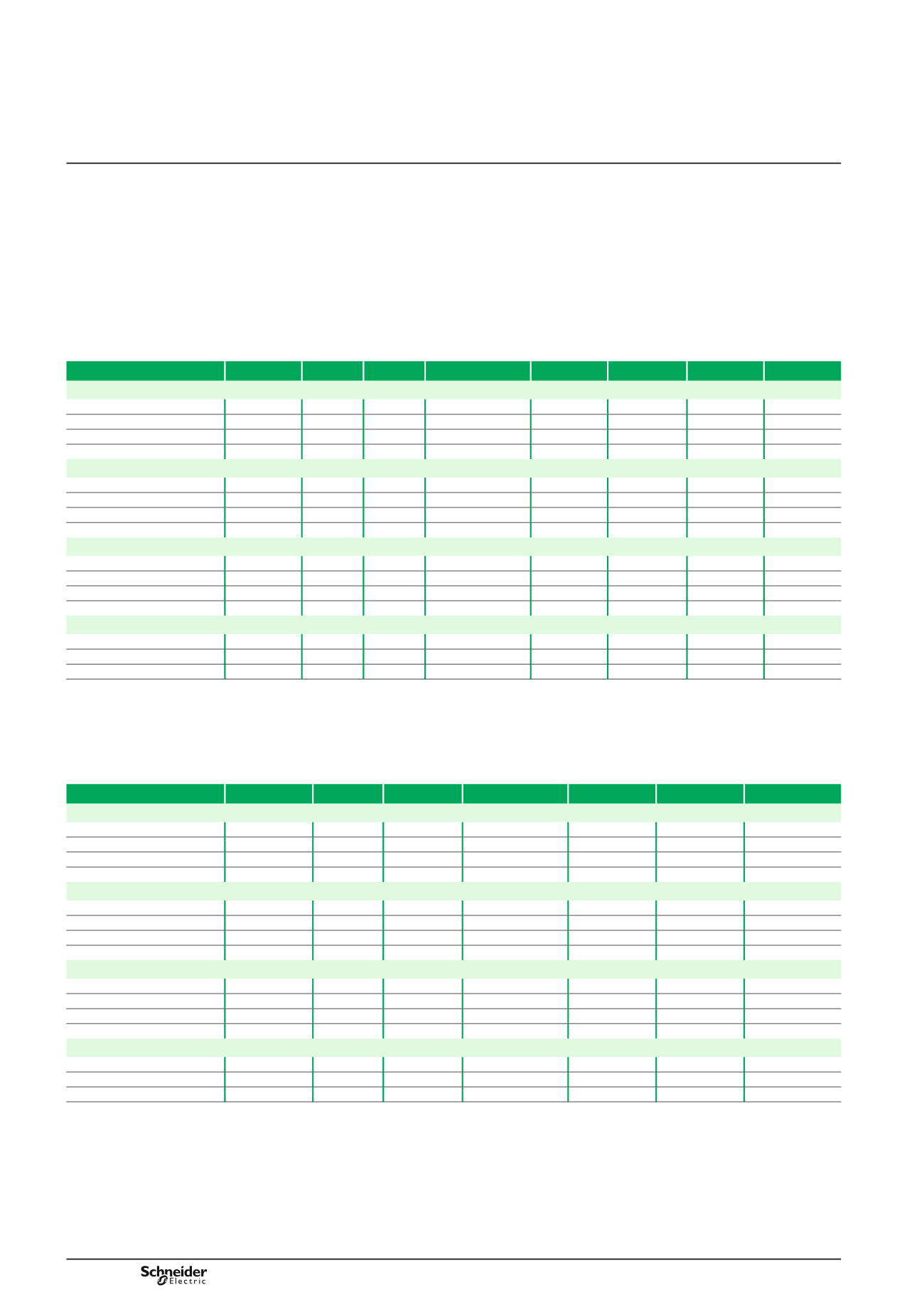

Specifications

Standards Units

Altuglas Polypropylene Polystyrene Polyamide 6 Polyamide 12

Mechanical properties

Tensile strength

ISO 257

MPa

30

35

24

40

30

Tensile strain

ISO 527

%

5

400

36

200

300

Impact resistance

ISO 179

kJ/m

2

20

20

63

No breakage No breakage

Notching resistance

ISO 179

kJ/m

2

3

5

50

31.2

15

Electrical properties

Stress point

IEC 60112

-

-

-

KB175

KB175

KB180

Surface strength

IEC 60093

ohm

≥ 1014

-

> 1013

1012

5 x 1010

Dielectric strength

IEC 60243

kV/mm 13-15

20

≤ 40

23

55

Specific resistivity

IEC 60093

ohm

cm > 1015

> 1016

> 1015

1011

3 x 1011

Physical properties

Softening temperature (Vicat B) ISO 306

°C

120-122

75 (vicat A)

79

230

140

Temperature resistance

-

°C

-20...+80

-10...+80

-15...+60

-20...+100

-50...+125

Water absorption

ISO 62

%

< 0.5

0.1 in 24 h

0.1 in 24 h

1.6

1.5

Specific weight

ISO 1183

kg/dm

3

1.18

0.91

1.06

1.14

1.03

Fire resistance

Oxygen index

ISO 4589

%

18.5

18

18

24

22

Glow wire resistance, 2 mm

IEC 60695-2 °C

-

650

650

750

650

Glow wire resistance, 3 mm

IEC 60695-2 °C

960

650

650

850

650