220

PB500477-12

PB500824-24

PB500807-24

SM

SM

SMX

SD

SDX

Telequick

Telequick

SF

SF

SM

SMX

SF

SFX

SFX

SFX

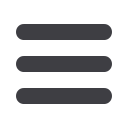

Accessories

Mounting

Mountingplates for floor-standing

enclosures

Characteristics Plain mounting plate

Perforated mounting plate "Telequick" Partial mounting plate

b

b

Depth adjustable with a pitch of

25 mm, provided with plastic shoe for

easier sliding.

b

b

Once the plate is fixed, in advanced

position, the sliding shoe can be easily

removed, to increase the available

plate surface.

b

b

In sets made up of two or more

enclosures with mounting plates, it is

possible to obtain a continuous plate

surface using intermediate mounting

plates (see page 221).

b

b

Allows the installation of switchgear without drilling

or screwing.

b

b

Plate designed for quick fixing of switchgear by means

of clip-on nuts ref.

NSYKNM3

to

NSYKNM6

.

b

b

Vertical continuity is guaranteed by the vertical

installation of plates.

b

b

The top plate must be fixed in the third hole, 80 mm

from the top frame.

Partial mounting plate, provided

with reinforcement flange on its

four sides.

Material

Galvanised steel

Zinc-coated steel

Galvanised steel

Fixing

Fixing options:

b

b

At the sides of the enclosure with the

orthogonal brackets (see page 224)

b

b

Back-to-back, with the brackets for

fixing the mounting plates in back-to-

back position (see page 225)

Fixing options:

b

b

Directly to the vertical uprights of the structure,

by means of self-tapping screws (only Spacial SF)

b

b

To the technical vertical uprights, by means of sliding

nuts, page 228; to standard uprights by means of flat

nuts, page 228 or self-tapping screws, and to cross rails

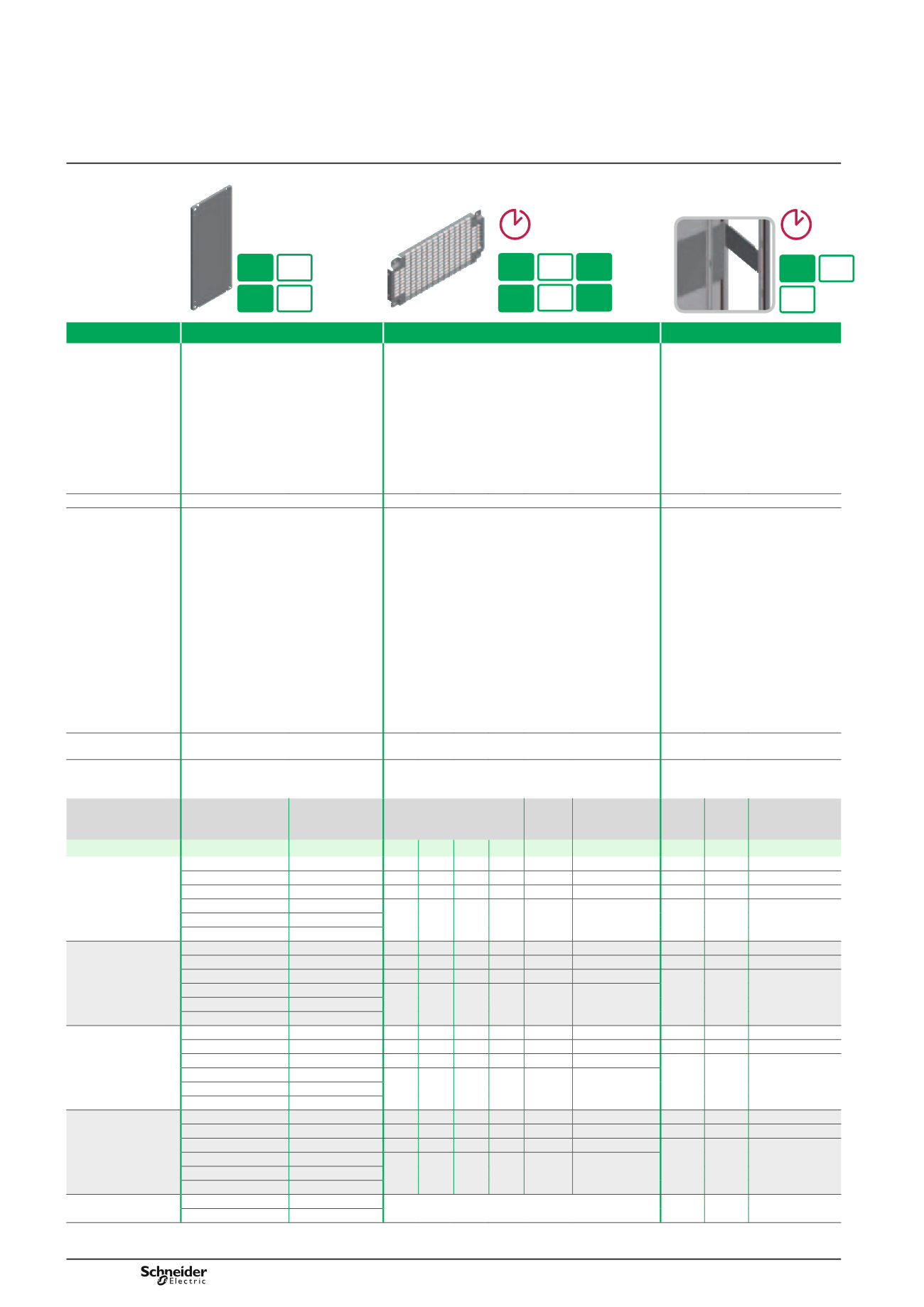

Fixing options:

b

b

Spacial SF, SFX:

v

v

Fixing to the vertical uprights

of the structure

v

v

Fixing to the technical or standard

vertical uprights, see page 228

v

v

For installations in advanced

position, fixing to cross-rails,

see page 232

b

b

Spacial SM:

v

v

Fixing by means of adaptation

profiles and 40-mm universal

cross-rails (1 row) in vertical

position, or also on horizontal

universal cross-rails

v

v

It can be mounted horizontally,

as a tray, by means of depthwise

cross rails, see page 232

Maximum load

600 kg in the back of the enclosure and

500 kg in the intermediate position

-

-

Supply

One mounting plate and sliding shoes One perforated mounting plate and fixing elements for

technical uprights and screws for fixing to the structure

or cross rails

Partial mounting plate and fixing

elements

Dimensions (mm)

Dimensions (mm) References

Plate height (mm)

Useful

surface

(dm

2

)

References Plate

height

(mm)

Plate

length

(mm)

References

Width (B)

Height (A)

D E F G

H B-100

600

1200

NSYMP126

450 200 -

100 11.4

NSYSTMP2260

247 500

NSYSPMP2560

1400

NSYMP146

450 425 -

325 22.8

NSYSTMP4560

247 750

NSYSPMP2575

1600

NSYMP166

450 575 125 475 30.4

NSYSTMP6060

397 500

NSYSPMP4060

1800

NSYMP186

450 800 250 700 11.9

NSYSTMP8260

597 500

NSYSPMP6060

2000

NSYMP206

2200

NSYMP226

800

1200

NSYMP128

650 200 -

100 15.9

NSYSTMP2280

247 700

NSYSPMP2580

1400

NSYMP148

650 425 -

325 31.8

NSYSTMP4580

397 700

NSYSPMP4080

1600

NSYMP168

650 575 125 475 42.4

NSYSTMP6080

597 700

NSYSPMP6080

1800

NSYMP188

650 800 250 700 58.4

NSYSTMP8280

2000

NSYMP208

2200

NSYMP228

1000

1200

NSYMP1210

850 200 -

100 20.4

NSYSTMP22100

247 900

NSYSPMP25100

1400

NSYMP1410

850 425 -

325 40.8

NSYSTMP45100

397 900

NSYSPMP40100

1600

NSYMP1610

850 575 125 475 54.4

NSYSTMP60100

597 900

NSYSPMP60100

1800

NSYMP1810

850 800 250 700 74.9

NSYSTMP82100

2000

NSYMP2010

2200

NSYMP2210

1200

1200

NSYMP1212

1050 200 -

100 24.9

NSYSTMP22120

247 1100

NSYSPMP25120

1400

NSYMP1412

1050 425 -

325 49.9

NSYSTMP45120

397 1100

NSYSPMP40120

1600

NSYMP1612

1050 575 125 475 66.5

NSYSTMP60120

597 1100

NSYSPMP60120

1800

NSYMP1812

1050 800 250 700 91.5

NSYSTMP82120

2000

NSYMP2012

2200

NSYMP2212

1600

1800

NSYMP1816

Order two 800-mm plates

397 1100

NSYSPMP40160

2000

NSYMP2016