49

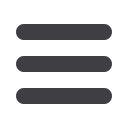

joint strips –

length to length coupling

ED275 - ED1100

1x

BTRCC

1x

CE25

1x

ED275

3x

BTRCC

3x

CE25

1x

ED275

n

Dimensions and weights

L

18

7 x 12·5

25

54 / 105 / 150 mm

50

600 mm

50

100

150

200

300

400 500

600

A B A B A B A B A B A B A B

CF54

2 0 2 0 2 0 2 0 2 1 2 2 2 3

CF105

– – 2 1 2 1 2 1 2 2 2 3 2 3

CF150

– – – – – – 2 2 2 2 2 3 2 3

CFG

– – 2 1 2 1 2 1 – – – – – –

The table below indicates the recommended quantity of ED275/ED1100

joint strips per width and also KITASSTR (p. 50) as a base coupler

Installation

Electrogalvanising after

manufacture

Hot dip galvanised after

manufacture

Stainless steel 304L

Stainless steel 316L

GC

304L

316L

For detailed information related

to inishes, refer to

p. 116-117

Key :

EZ

n

Assembly

All dimensions (mm) are nominal

Straight lengths : see p. 38-44

➔

ED275

275

0·08

0·10

0·08

0·08

ED1100

1 000

0·49

0·55

–

0·38

mm

L

Cat. No.

GC

316L

Weight (kg)

304L

EZ

Use to provide additional support for length to length coupling

Fasteners are required to secure joint strips to the tray (see below)

ED275 supplied in packs of 50 without fasteners. ED1100 supplied

singly without fasteners. Not suitable for 30 mm or 80 mm deep tray

Joint strips attach to the side wire of the tray across the joint when

used as a length to length coupler. Fasteners required (not supplied)

For lighter loads, use a single

fastener

For heavier loads, increase the

number of fasteners

A

A

= side coupling

B

= base coupling (CAA)

All weights are given in Kilograms (kg)

Please use Cat. No. when placing your order, see p. 18

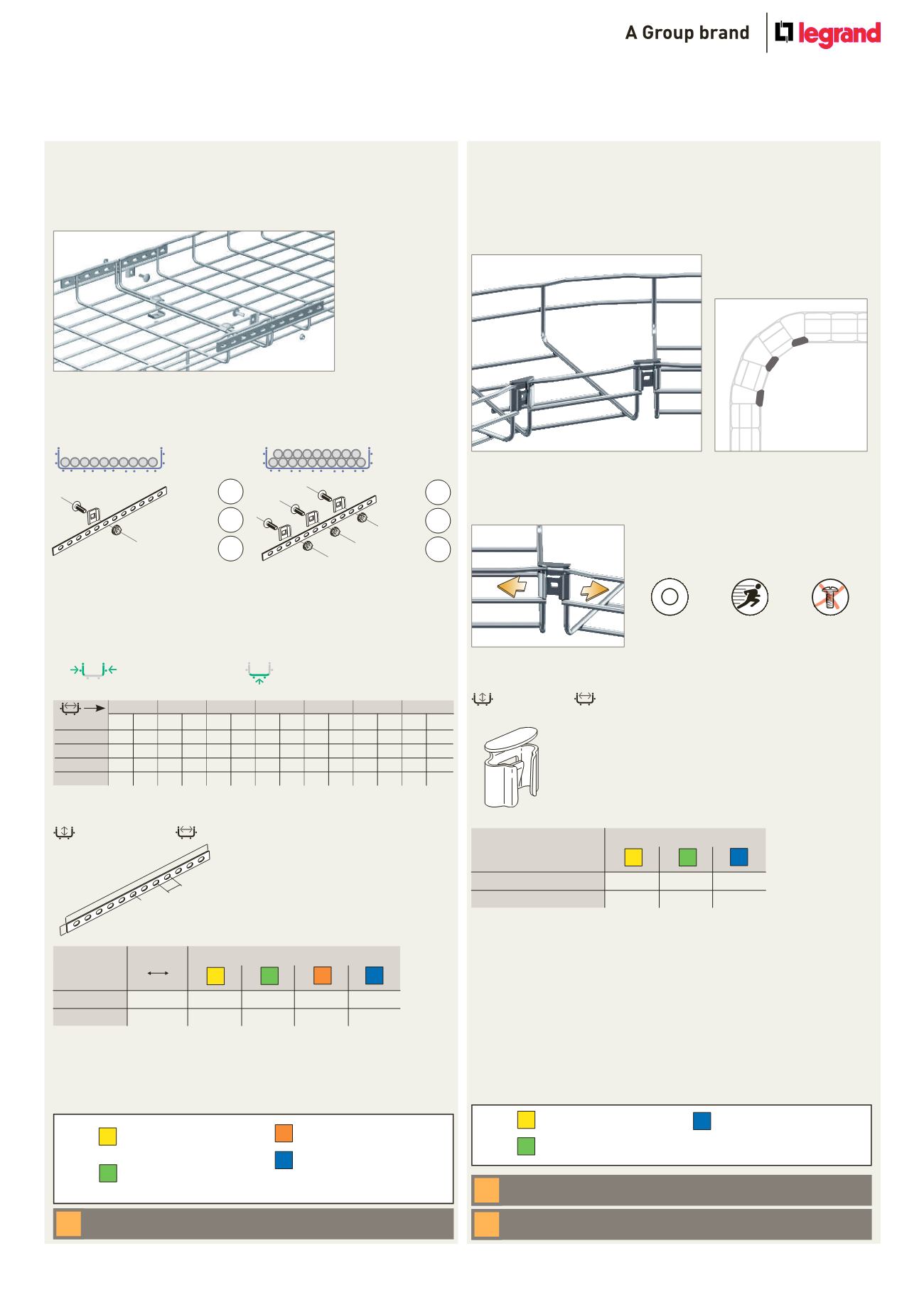

couplers –

fabricated fittings

FASLOCK AUTO

n

Dimensions and weights

Installation

30

150 mm

100

600 mm

n

Assembly

Installing FASLOCK AUTO : see p. 97-99

➔

FASLOCK AUTO S

0·01

0·01

0·01

FASLOCK AUTO XL

0·01

0·01

0·01

Cat. Nos.

316L

Weight (kg)

DC

EZ

FASLOCK AUTO is positioned on the internal angle of a radius bend after

steel wire cable tray has been cut. No fasteners required

FASLOCK AUTO is used to form radius bends. For 100 mm and 200

mm wide steel wire cable tray use FASLOCK AUTO S (small). For 300

mm wide to 600 mm wide tray use FASLOCK AUTO XL (large)

Supplied in packs of 25. No additional fasteners or tools required.

For detailed installation instructions see p. 97-99

P

A

T

E

N

T

E

D

Patented

Fast

assembling

Fixing without

nuts and bolts

All dimensions (mm) are nominal

All weights are given in Kilograms (kg)

Please use Cat. No. when placing your order, see p. 18

Clip FASLOCK AUTO into place. Safety

edges protect both the cables and the

installer

Creating a radius bend : see p. 98-101

➔

Electrogalvanising after

manufacture

Geomet

Stainless steel 316L

316L

For detailed information related

to inishes, refer to

p. 116-117

Key :

DC

EZ