42

®

INNOVATORS IN CABLE MANAGEMENT

�

n

Dimensions and weights

straight lengths -

CF105

technical information

3 000

105

100

50

W

n

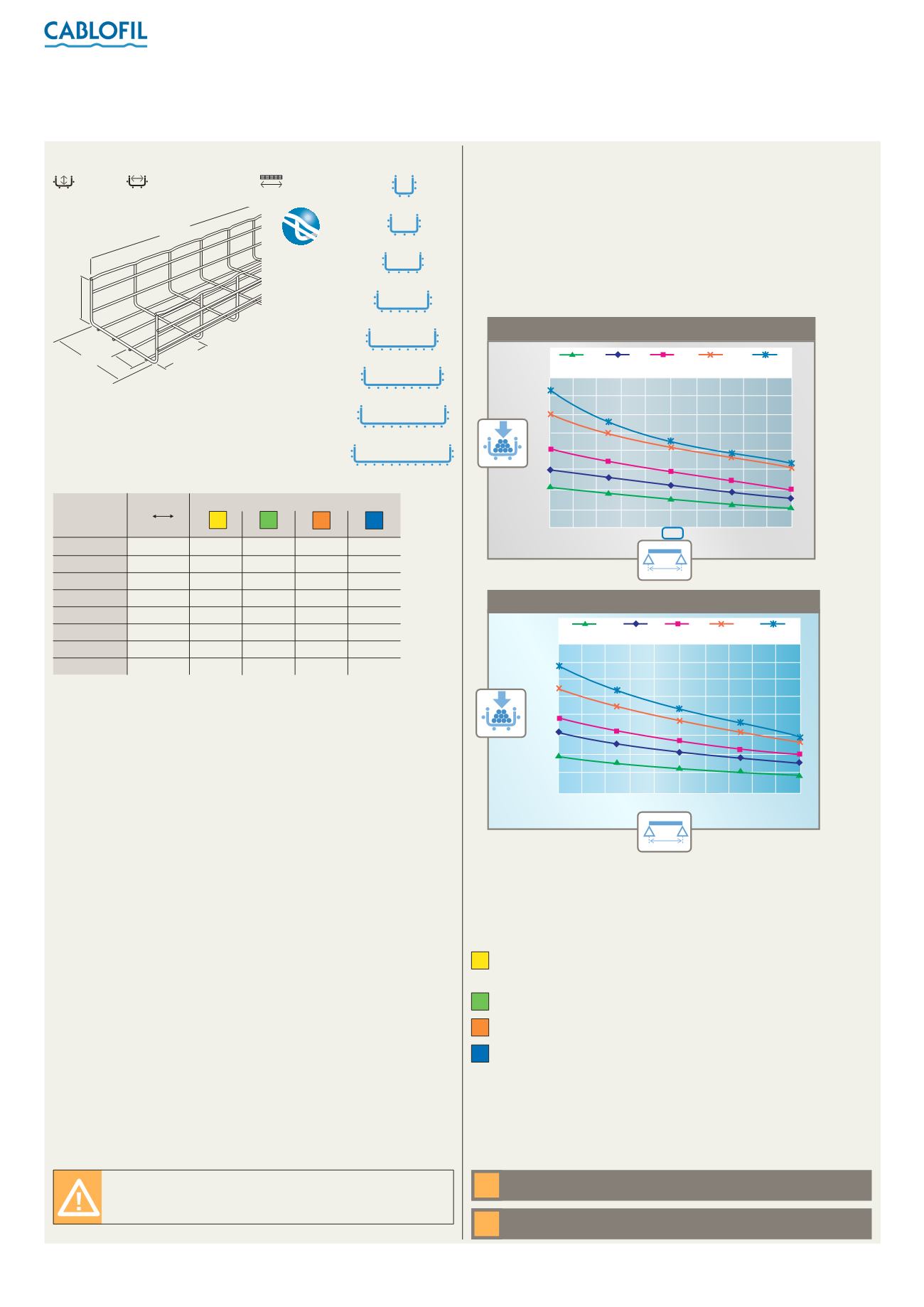

Loading graphs

CF105/100

CF105/150

CF105/200

CF105/300

CF105/400

CF105/450

CF105/500

CF105/600

105 mm

100 mm

Ú

600 mm

3 m

mm

L

kg/m mm

L

daN

F

1

mm

L

2

mm

H

kg/1 kg/100 daN.m

mm mm

L

W

CF105/100

100

4·07 4·23 3·50 3·50

CF105/150

150

5·23 5·43 3·97 3·97

CF105/200

200

6·13 6·37 5·14 5·14

CF105/300

300

9·15 9·51 7·92 7·92

CF105/400

400

10·42 10·83 9·06 9·06

CF105/450

450

11·25 11·40 9·45 9·45

CF105/500

500

11·69 12·15 9·63 9·63

CF105/600

600

12·96 13·46 10·20 10·20

Cat. Nos.

EZ

GC

304L

316L

Weight (kg/3 m)

All weights are given in Kilograms (kg) and are for a 3 m straight length

Please use Cat. No. when placing your order, see p. 13

B

o

r

d

S

é

c

u

r

i

t

é

B

r

e

v

e

t

é

Safety

edge

n

Finishes

Standard stocked finish :

EZ

Electrogalvanising after manufacture

Additional finishes :

GC

Hot dip galvanised after manufacture

304L

Stainless steel 304L

316L

Stainless steel 316L

For detailed information related to finishes, refer to

p. 116-117

Dividers : see p. 46

➔

Couplers : see p. 48-51

➔

Sheared steel (particularly stainless steel) does

have relatively sharp edges and protective gloves

must be worn during handling

All dimensions (mm) are nominal

Load tests carried out to IEC 61537 (safety factor 1·7 + joint

1

/

5

th

of the

way along the span). Permissable load should include all cable loads

and any other additional loads (eg: wind, snow)

NOTE:

For more information on loadings, see

p. 125

kg/m

mm

EZ - GC

CF105/100

CF105/150 CF105/200 CF105/300

è

400 CF105/500

è

600

1500 1600 1700 1800 1900 2000 2100 2200 2300 2400 2500

160

140

120

100

80

60

40

20

0

kg/m

mm

304L - 316L

160

140

120

100

80

60

40

20

0

CF 105/100

°

150 CF105/200 CF105/300 CF 105/400 CF 105/500

°

600

1500 1600 1700 1800 1900 2000 2100 2200 2300 2400 2500

The permissable load stated in this catalogue represents the load

that Cablofil steel wire cable tray is guaranteed to be able to bear. It

assumes loads are evenly spread and is given in daN/m. The standard

permits a deflection equivalent to 1/100th of the span. Legrand

imposes a stricter limit of 1/200th for both safety and aesthetic reasons.

For example, Legrand voluntarily restricts deflection to 10 mm for a

span of 2 m, whereas the standard would allow 20 mm.