klik.system | Specification guide to prefabricated wiring systems

16

Protective conductor arrangement for high

protective conductor currents

Regulation 543.7.1.103 stipulates that, when the cumulative

protective conductor current of the circuit is likely to exceed

10 mA, it shall have a high integrity protective connection

complying with one or more of the five listed options.

Therefore, the designer should evaluate the likely

protective conductor currents in relevant parts of the

prefabricated wiring system, including those supplying

luminaires. This is because it is recognized, that some

luminaires can produce currents in the protective conductor

e.g. high-frequency fluorescent luminaires. When a significant

number of luminaires are supplied from a common system,

the protective conductor current may exceed 10 mA.

Wherever possible, protective conductor current should be

determined by consulting information provided by the

luminaire manufacturer.

A protective conductor current not exceeding 10 mA may be

difficult to avoid in particular sections of a prefabricated

wiring system e.g. the home run cable and link lead to a

Lighting Distribution Unit (LDU) therefore, a high integrity

protective connection would be required. However, the

system arrangement after the home run / LDU link lead could

be configured using LDUs supplying a suitable number of

luminaires, thus avoiding cumulative protective conductor

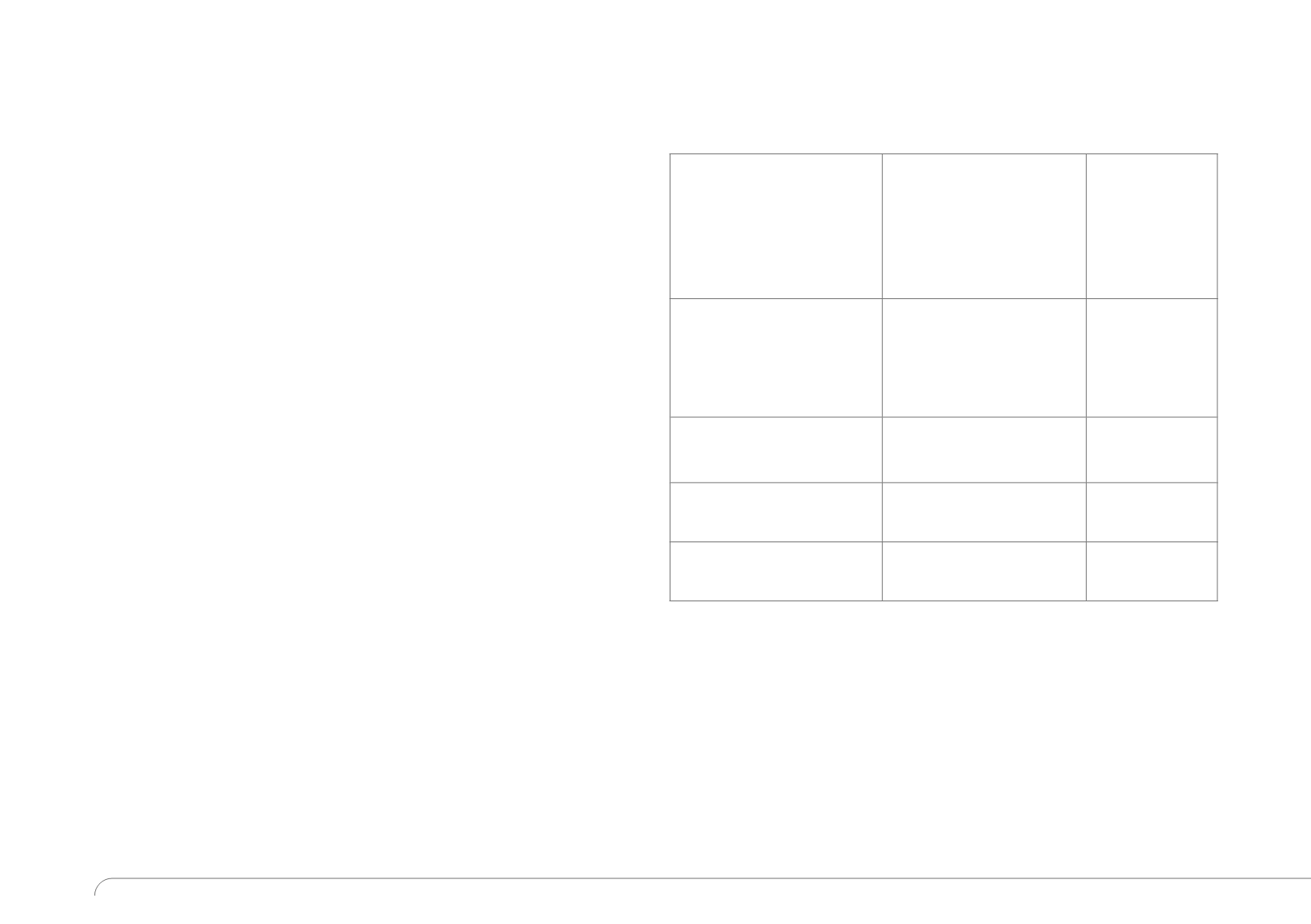

currents above 10 mA. Table 3 provides examples of

luminaire leakage current values.

Example

Luminaire type

Maximum

protective

conductor

current

(mA, r.m.s.)

BS EN 60598-1:2008 Class I intended for

permanent

connection. Supply

current ≤ 7 A.

3.5

Test result for specific

luminaire

Fluorescent with HF

ballast

0.2

Manufacturers data

Per fluorescent HF

ballast

0.5

Manufacturers data

LED driver: output

power 150 W

0.7

Table 3 - Examples of leakage current values

for conventional luminaires

“ A high integrity protective connection

may be required ”.