Total Solution to Earthing & Lightning Protection |

9AKK106354A3360

6/5

6

Connectors and terminations

An effective earthing system relies on joints and connections

to have good electrical conductivity with high mechanical

strength. Poorly chosen or badly installed joints and

connectors can compromise the safe operation of an earthing

system. We offer a range of connectors and termination

methods to suit a wide range of applications:

4. FurseWELD exothermic welding

A simple, self-contained method of

forming high quality electrical connections

which requires no external power or

heat source. Connections are made using

the high temperature reaction of

powdered copper oxide and aluminium.

FurseWELD connections allow conductors to carry higher

currents than other types of connections. They will

never loosen, are highly conductive and have excellent

corrosion resistance.

5. Compression connectors

For applications where exothermic

welding is not appropriate for creating

permanent connections, compression

connectors may be used.

Compression connectors produce very

robust joints which can be buried in the

ground or in concrete.

6. Mechanical clamps

Where permanent connections are not

appropriate, mechanical clamps offer the

ideal solution. These are typically used on

smaller scale installations where periodic

disconnection for testing is required.

All Furse mechanical clamps are

manufactured from high copper content

alloy. They have high mechanical

strength, excellent corrosion resistance

and conductivity.

7. Earth inspection pits

Regular inspection and testing of the

earthing system is essential. Inspection

pits allow easy access to earth

electrodes and conductors to facilitate

this procedure.

8. Earth bars

Earth bars are an efficient and

convenient way of providing a common

earth point. Integral disconnecting

links mean the earth bars can be isolated

for testing purposes.

9. Earth electrode backfills

Earth electrode backfills are to be used

in areas where required resistance

levels are difficult to achieve. These

products effectively act to increase the

electrode’s surface area thus lowering its

resistance to earth.

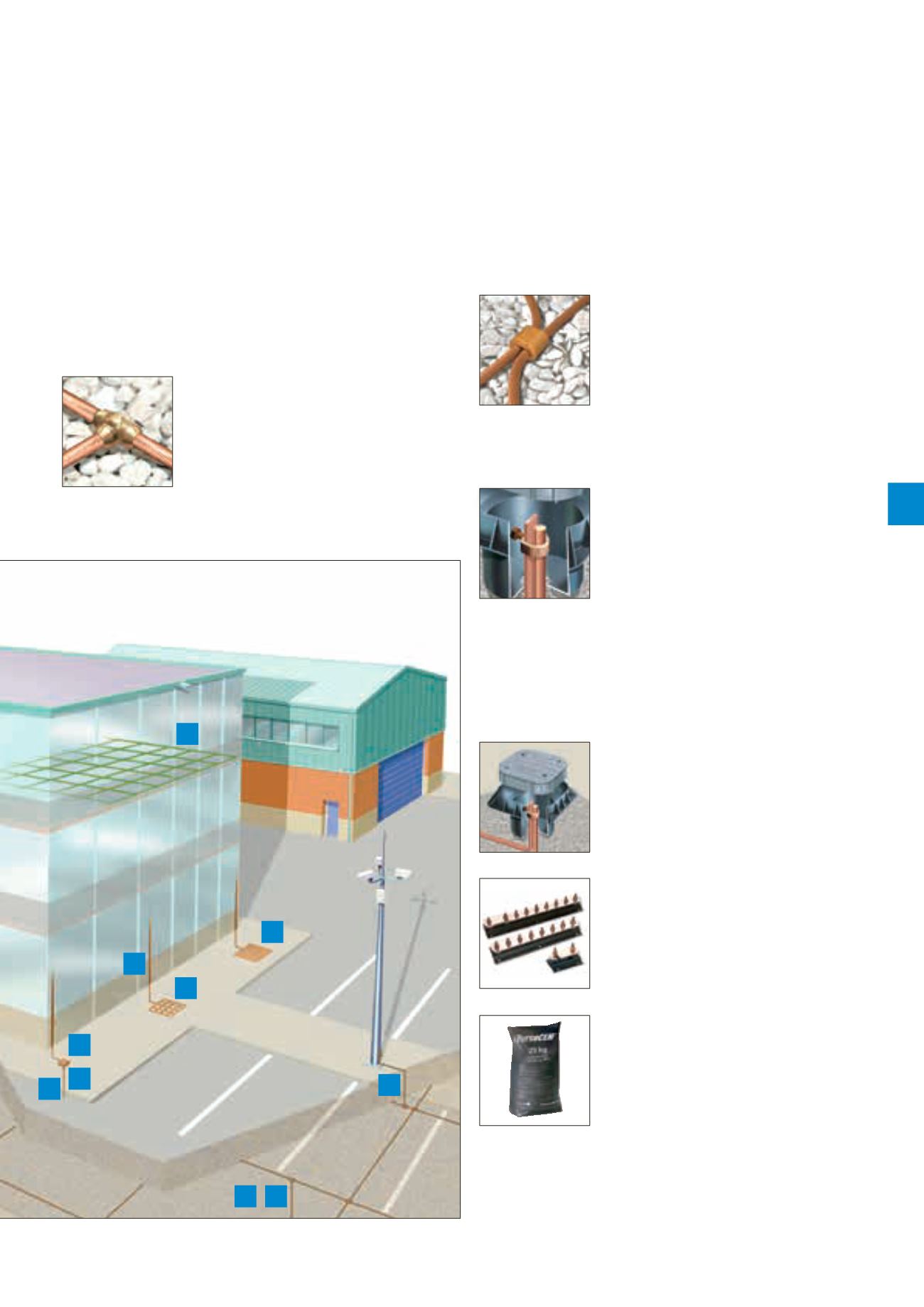

This illustration is designed to demonstrate the main aspects and

individual components of an earthing system. It is not

intended to represent an actual scheme conforming to a particular

code of practice. The drawing is not to scale.

3

6

7

1

5

6

7

8

9

2

3

2

1

1

4

9