9/4

Total Solution to Earthing & Lightning Protection |

9AKK106354A3360

9

FurseWELD

Introduction

Moulds

The FurseWELD system of exothermic welding uses moulds

to contain the exothermic reaction that creates safe and

robust connections. Different types of moulds are available,

whose use depends on the requirements of the project.

Full-sized graphite moulds

Market leading FurseWELD graphite moulds are extremely

robust and capable of producing up to 75 connections each,

if not more when properly maintained.

Mini-Moulds

FurseWELD mini-moulds are a cost effective alternative to

full-sized moulds, especially where lower numbers of

connections are required. They are smaller overall, less robust

and therefore lower priced. Care is required in order to

achieve similar service lives to full-sized moulds.

FurseWELD products

–– A powder cartridge is required for each joint to be made

–– Handle clamps enable the mould to be handled when hot,

and the two halves of the mould to be opened and

clamped together

–– Packing is required when welding to reinforcing bar

Conductors

The range of FurseWELD moulds is designed to work with all

common conductor formats.

–– Flat tape conductor

–– Stranded conductor

–– Solid circular conductor

Conductors must be in the orientation shown to achieve

the correct connection. Furse offers technical support

to assist with selection of joint type. Please contact us where

unsure, e.g. where you may be using compacted stranded

conductor.

If connections shown do not meet your requirements,

please contact your local sales office.

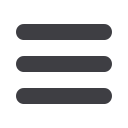

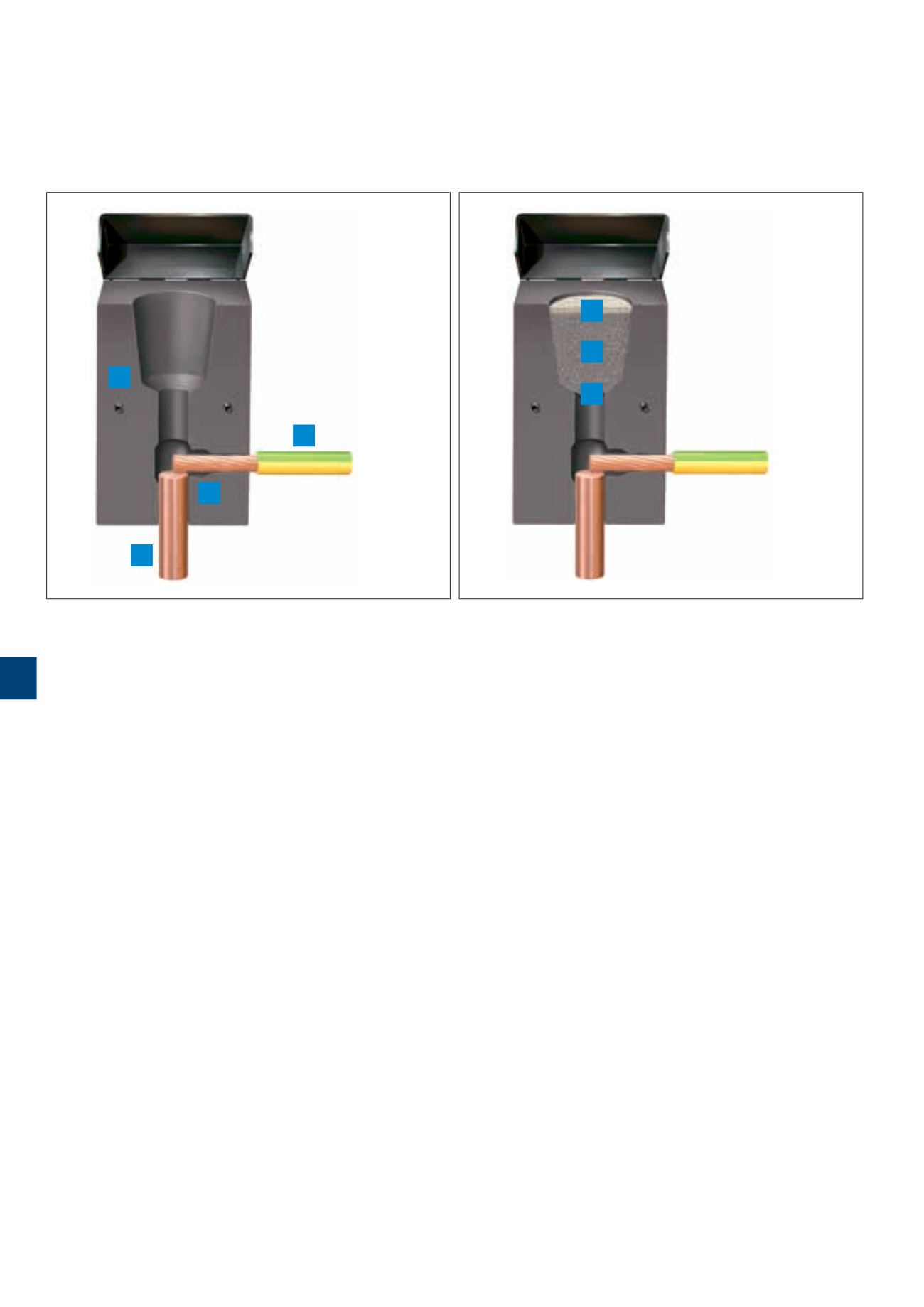

Making a FurseWELD joint is a simple procedure

1

2

Locate the steel retaining

disc in the base of the

crucible (D). Pour in the weld

powder (E) followed

by the starting powder (F).

Ignite starting powder

with a spark gun.

Locate the conductors (A)

to be joined in the weld

cavity (B) and close the

mould (C).

C

A

B

A

F

E

D